The OWD series is part of a comprehensive portfolio that covers the capacity range of all BITZER screw compressors, both in single and parallel operation, and is compatible with a variety of synthetic refrigerants like HFC, HFC-HFO blends, HFO and hydrocarbons.

Although specially developed for tried-and-tested HS and OS screw compressors, it also offers a reliable solution in combination with the products of other manufacturers.

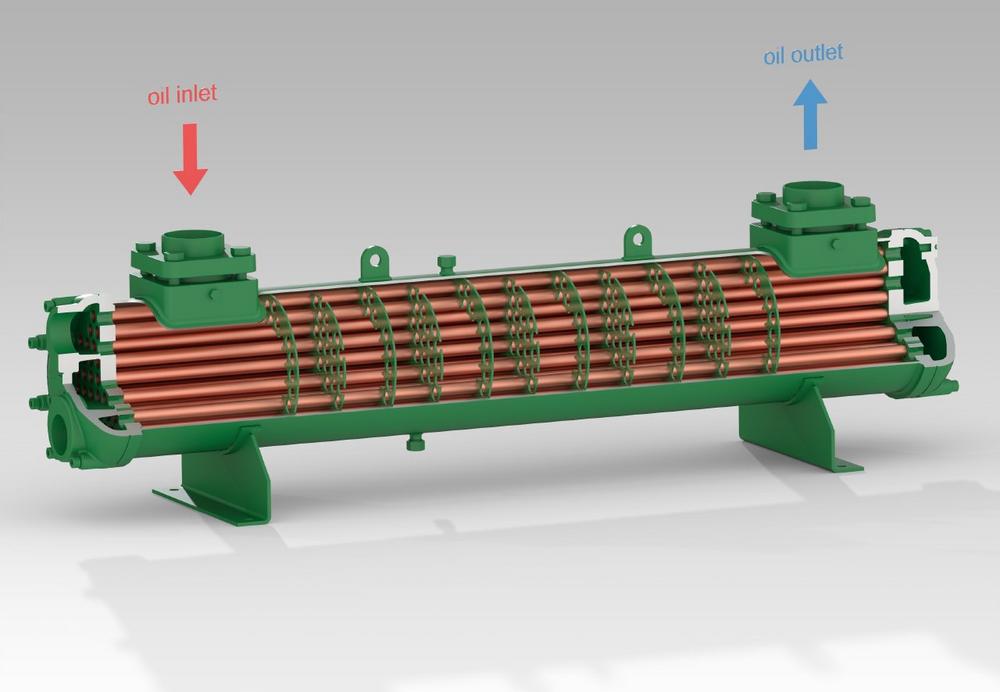

It therefore takes oil cooler efficiency and versatility to a whole new level – with optimised performance, increased compatibility and maximum adaptability for many different applications. (Fig. 1)

A wide capacity range paired with innovative design

In addition to a much wider capacity range, the OWD series also offers maximum oil cooler capacity of up to 300 kW, regardless of the operating conditions, which makes it possible to efficiently tackle even the most demanding cooling tasks in high temperature heat pump and low temperature applications. A special feature of this series is its use of disc and doughnut baffles, ensuring even oil distribution throughout the cooler tubes. This technology improves heat transfer on the oil side and reduces flow surges with minimal pressure loss.

OWD oil coolers are available in 17 product variants, which come in 2-pass and 4-pass designs.

This flexibility enables optimal adjustment to the specific requirements of different applications. (Fig. 2)

The technological benefits of disc and doughnut baffles

The new disc and doughnut baffles enable a symmetric flow for even oil distribution and maximum heat transfer. The optimised flow control improves the flow pattern and minimises unwanted turbulence, which not only increases efficiency, but also boosts operational stability and thus extends the lifetime. Regardless of the size of the oil cooler, the OWD series optimises flow velocity with adjusted baffle distances, thus achieving an optimal balance between heat transfer and pressure drop, even with larger devices.

The OWD series is designed to reduce dead space in the heat exchanger compared to its predecessor, the OW series, which is a great benefit. The result is increased efficiency in the use of the entire tube surface and a boost in heat throughput. In addition, the optimised space requirement enables integration of a higher number of tubes for ultra-high power density. Calculations show that the new oil cooler series reduces CO2 equivalents by more than 40% compared to the predecessor and thus makes a key contribution to sustainability.

The baffles are also temperature-resistant and can easily withstand temperatures of over +150°C, making the OWD series well equipped for demanding environments.

Using state-of-the-art methods such as flow simulations (CFD) and extensive laboratory experiments, the OWD series has been specially developed for applications in refrigeration and heat pump technology. Thanks to precise coordination with requirements and optimisation for use with BITZER products, it ensures extraordinary efficiency and operating reliability. (Fig. 3)

A wide range of applications

Designed for reliable use in a whole host of applications, the OWD series is compatible with fresh water and seawater and covers a wide range of temperatures and pressures. It can handle oil temperatures of –20°C to +150°C, oil pressures of up to 32 bar and water temperatures of –20°C to +95°C at 10 bar.

OWD oil coolers fulfil stringent requirements in terms of temperature resistance, pressure strength and corrosion protection, and comply with the stipulations of the CE-PED, SELO CML, BV and DNV certifications, which qualifies them for use in heat pump and low temperature applications in maritime and industrial sectors as well as in the high temperature range.

Selection and software

The OWD series can be combined with BITZER open drive OS and semi-hermetic HS screw compressors in the BITZER SOFTWARE.

BITZER SOFTWARE allows users to manually select the compressor of their choice or recommends a suitable compressor based on capacity, operating conditions and specific requirements. Once the compressor has been specified, the accessories can be selected. If it is an HS or OS compressor, the BITZER SOFTWARE calculates the required cooling capacity and, if necessary, recommends a suitable oil cooler. Alternatively, the user can select the “External oil cooling” option manually in the “Additional cooling” section. With all the relevant technical data presented in a straightforward format, the user can make adjustments based on their requirements and review the selection. Temperatures can also be customised on the secondary page, thus guaranteeing optimal coordination of components. This automated process simplifies configuration and ensures an efficient, reliable system design. (Fig. 4)

Summary

The new OWD series offers an impressive combination of high heat transfer, minimal pressure drop, efficiency and versatility. With innovative technologies like the disc and doughnut baffles, a highly expanded capacity range and an increased range of application, it is the ideal choice for cooling applications and high temperature heat pumps with low-GWP refrigerants, which require a reliable, high-performance oil cooler.

Thanks to its robust design and adaptability, it also fulfils the most stringent requirements and is setting new benchmarks in oil cooling.

As an independent specialist for refrigeration, air conditioning and heat pump technology, BITZER is present all over the world: with products and services for refrigeration, air conditioning and process cooling as well as transport, BITZER ensures optimum temperature conditions for trade in goods, industry processes and indoor climate control – always striving for the highest possible energy efficiency and quality. BITZER is represented all over the world with 75 sites in 41 countries, including its sales companies and production facilities. Trade and service partners included, the BITZER network of manufacturing, development and sales extends to almost all countries in the world. In 2024, 4,500 employees generated a turnover of €1.12 billion; expenditure for research and development totalled €67 million.

Overview of images

Images may only be used for editorial purposes. This usage is free of charge if ‘Photo: BITZER’ is provided as the source and a free copy of the publication is sent. Images may not be modified or altered, except to crop out the background surrounding the main subject.

BITZER Kühlmaschinenbau GmbH

Peter-Schaufler-Platz 1

71065 Sindelfingen

Telefon: +49 7031 932-0

Telefax: +49 7031 932-147

http://www.bitzer.de

Head of Corporate Communications and Marketing Content

Telefon: +49 (7031) 932-4327

Fax: +49 (7031) 932543-70

E-Mail: stefanie.holst@bitzer.de

![]()