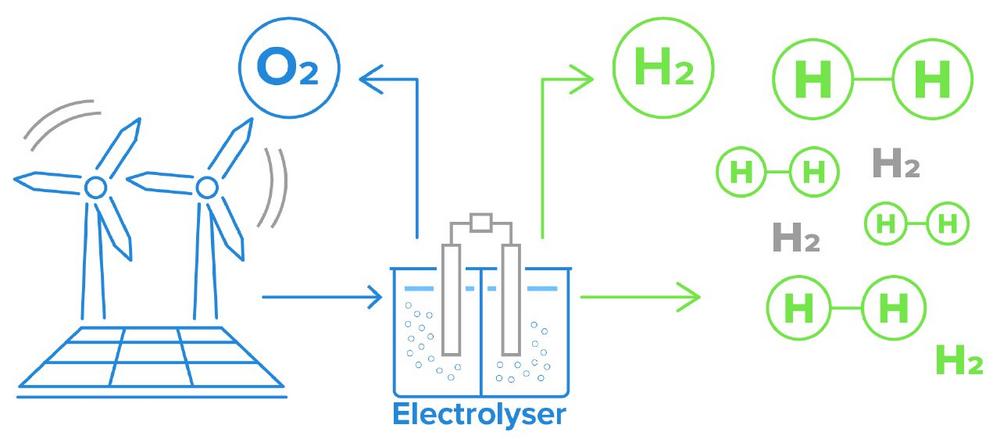

The efficiency of an electrolyser is defined by how much hydrogen it can generate relative to the electrical energy consumed. Therefore, accurately measuring the hydrogen output is critical.

However, the hydrogen generated is initially saturated with water vapour and most flow meters are not very accurate when measuring wet or humid hydrogen due to the different properties of hydrogen and water vapour. It is essential to dry the hydrogen after it exits the electrolyser and before the flow measurement.

LEANCAT (https://lean-cat.com/), a manufacturer and developer of hydrogen systems, including testing stations for electrolysers, conducted a study to determine how humidity affects the accuracy of thermal gas mass flow meters. Their findings showed that if the hydrogen’s dewpoint is above -10°C, calibration errors become significant.

Based on these results, we strongly recommend drying hydrogen coming from a electrolyser to a dew point of -10°C or lower when using a thermal mass flow meter or controller. For optimal performance, the device should be calibrated with real hydrogen, offer a dynamic range of at least 1:100, provide excellent long-term stability, and exhibit a low pressure drop.Vögtlin offers hydrogen flow solutions ranging from 0–0.01 to 0–2900 ln/min that meet these requirements.

In conclusion, drying hydrogen to a dew point of -10°C or lower is essential for accurate measurement.

We recommend consulting with our experts to determine the best solution for your specific application.

Vögtlin Instruments GmbH

St. Jakob-Strasse 84

CH4132 Muttenz

Telefon: +41 (61) 756 63 00

Telefax: +41 (61) 756 63 01

https://www.voegtlin.com

Marketing/Kommunikation

Telefon: +41 61 756 63 314

E-Mail: s.ahrens@voegtlin.com

![]()