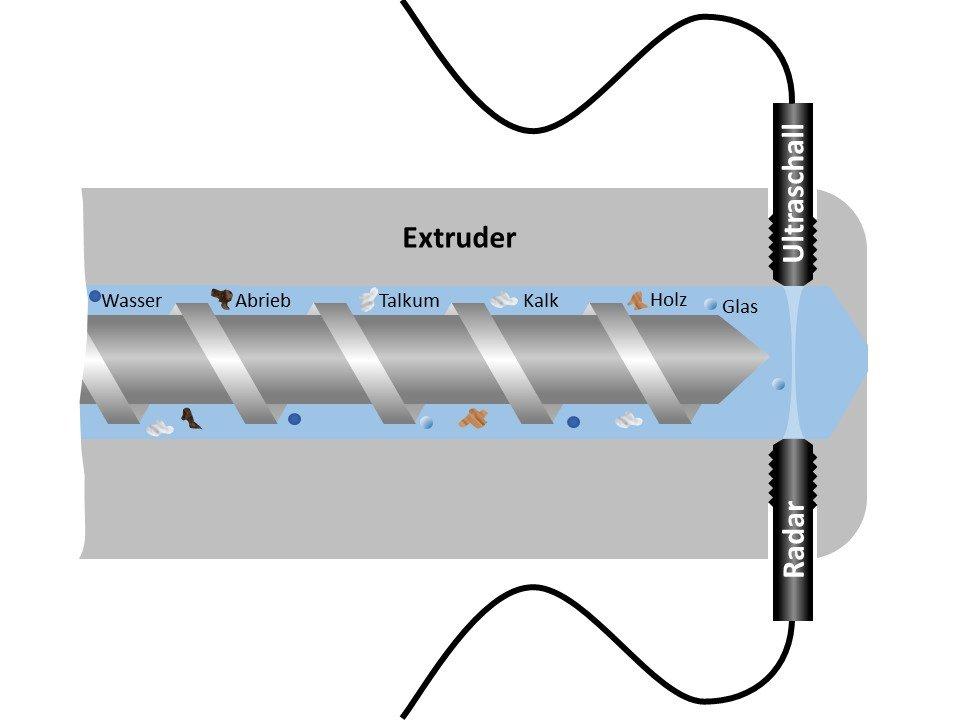

Whether glass particles, wood residues, or metal abrasion—foreign materials in plastic melts can have serious effects on product quality. They pose a particular challenge during extrusion and injection molding. The SKZ (Plastics Center) offers a practical solution for this: advanced inline testing systems that detect even the smallest contaminants at an early stage, thereby significantly improving quality and process reliability in plastics processing.

Technology that sees further – ultrasound and microwaves instead of just metal detection

Unlike conventional metal detectors, the systems developed at SKZ detect not only metallic but also non-metallic foreign materials such as glass, cardboard, wood, or stone. This is made possible by the use of ultrasonic and microwave methods that measure continuously during the running process – without interrupting or impairing it.

In addition, the systems are also able to identify non-homogeneous plastics or degraded material. This sets them apart from conventional screening inserts and opens up new possibilities for quality assurance in sensitive or highly specialized production processes.

Many years of development – industry-oriented solutions

The SKZ has been working on the development of industrial-grade measuring and testing systems for plastic melts for over ten years. The solutions are developed in close cooperation with industry – from the initial feasibility test to complete integration into existing production lines.

As a member of the Zuse Community, SKZ not only offers technological expertise, but also the entire process chain from a single source: from conception and validation to integration into the manufacturing process, SKZ ensures that the customized solutions

More quality, less waste

SKZ’s inline testing technology enables quality control where it has the greatest impact – directly in the melt. This means that foreign materials are precisely detected before the final component is manufactured. Manufacturing companies benefit from higher product quality, less scrap, and more efficient production.

The SKZ is a climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

SKZ – Das Kunststoff-Zentrum

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

Senior Scientist | Non-destructive Testing

Telefon: +49 (931) 4104-469

E-Mail: p.pfeffer@skz.de

![]()