In many companies, knowledge about the products used is stored in device databases. In daily practice, however, existing projects or project templates suitable for a new project are copied and then adapted to the tasks at hand. Yet components that have been discontinued or existing errors, for instance in the drilling patterns for a component, etc., are often copied into the new project. These errors are typically only noticed much later, either in procurement or production. These require adjustments and ultimately lead to increased costs and longer throughput times. It would be much better if relevant changes were known about earlier in the process and could be directly accounted for.

Changes visible immediately

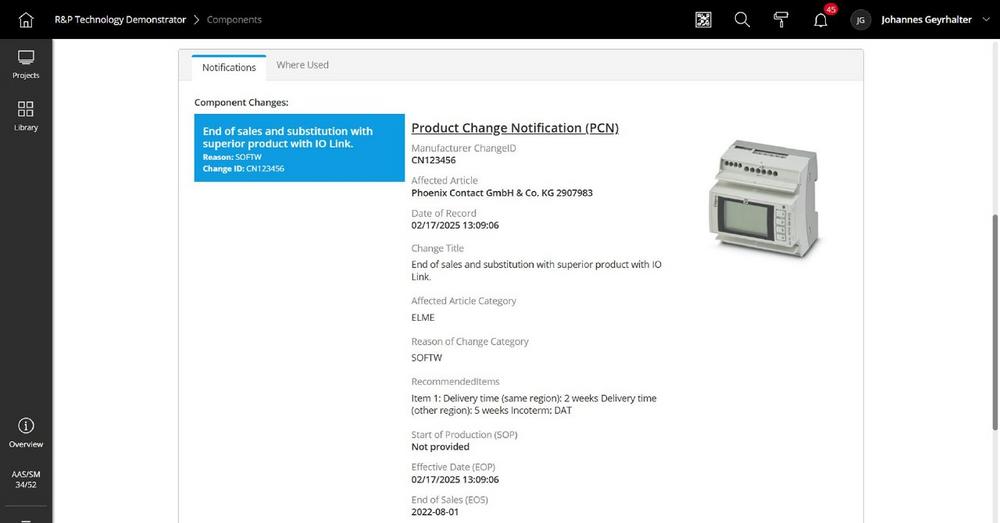

This is precisely where the product change notifications (PCNs) come into play. Specialists at Eplan and Phoenix Contact have developed a solution based on the Asset Administration Shell (AAS) that will be presented at the SPS trade show. Phoenix Contact provides information about its own components and any potential changes using AAS. The Eplan software receives this information via the AAS and thereby updates the Data Portal. This results in a message on the portal, which is automatic, consistent and error free. Designers thus receive an immediate notification about the changes and can immediately see where the affected parts are installed in existing equipment and can then quickly and efficiently respond as needed. The prerequisite for this is that the customer project is stored in the Eplan cloud.

Collaboration in the ecosystem

Eplan Senior VP for Strategy & Corporate Programme Dr Marco Litto explains: “With PCN and AAS, component manufacturers can provide their customers with targeted information or, as an example, important firmware updates that can be necessary after a security vulnerability has been discovered. Machine builders, system integrators and control cabinet manufacturers hereby receive important, relevant update information. They can incorporate the changes into their engineering processes early on, almost in real time.”

The Asset Administration Shell (AAS)

AAS is a manufacturer-independent standard developed by the IDTA that all manufacturers have agreed to use to improve cooperation. AAS allows complex data sets to be quickly reviewed, makes relevant information visible and helps alternative to quickly be found where necessary. Why is this so important? It now makes it possible to digitally depict the cooperation between automation companies. The benefits are clear: faster reaction to product changes, automated procurement and higher equipment availability.

The AAS was developed by the IDTA and is increasingly being used in more and more automation processes. Thanks to its complete interoperability, it paves the way for greater digital value creation. It simplifies data management for both non-smart and smart devices. Furthermore, it depicts the entire life cycle of products, devices, machines and plant systems. This occurs based on the digital twin, which contains all the information that characterises the features and behaviours of an asset. Traditionally, an AAS consists of a series of submodules that describe all the data and functionality of a specific asset, including features, properties, states, parameters, measurement data and capabilities.

In conclusion

Product change notification and AAS open up new horizons for change management because outdated components can be replaced in good time and delivery bottlenecks avoided. At the same time, the visibility of component manufacturers in the engineering workflow is increased – directly at the critical interface with the customer. Eplan hereby makes partners such as Phoenix Contact an active part of the ecosystem of collaborative engineering – standardised, interoperable and future-proof.

Eplan provides software and service solutions in the fields of electrical, automation and mechatronic engineering. The company develops one of the world’s leading design software solutions for machine and panel builders. Eplan is also the ideal partner to streamline challenging engineering processes.

Both standardised as well as customised interfaces to ERP and PLM/PDM systems ensure data consistency along the whole value chain. Working with Eplan means boundless communication across all engineering disciplines. No matter whether small or large enterprises: Customers can apply their expertise more efficiently. Worldwide, Eplan supports 73,100 customers. Eplan wants to grow further with customers and partners and pushes integration and automation in engineering forward. Within the Eplan Partner Network, open interfaces and seamless integrations are realised together with partners. „Efficient engineering“ is the focus.

Eplan was founded in 1984 and is part of the owner-operated Friedhelm Loh Group. The group operates worldwide, with 13 production sites and 95 international subsidiaries. It has 12.600 employees and posted revenues of €3,1 billion euros in fiscal 2024. In 2023, the Friedhelm Loh Group was presented with the “Best Place to Learn” and “Employer of the Future” awards.

For more information, visit www.eplan-software.com and www.friedhelm-loh-group.com.

EPLAN GmbH & Co. KG

An der alten Ziegelei 2

40789 Monheim

Telefon: +49 (2173) 3964-0

Telefax: +49 (2173) 3964-25

http://www.eplan.de

Presse- und Öffentlichkeitsarbeit

Telefon: +49 (2173) 3964-180

Fax: +49 (2173) 3964-163

E-Mail: hagelschuer.b@eplan.de

![]()