- Outdated drives and motors replaced with a new drive system, featuring 20 percent higher torque, thereby extending the plant’s aluminum processing capabilities

- This comprehensive upgrade covers the plant engineering, electrics and automation, equipment procurement and manufacturing, and installation and commissioning supervision

- The project highlights the companies’ excellent partnership built on innovative solutions

For Gulf Aluminium Rolling Mill B.S.C. (GARMCO), a leading aluminum producer based in Manama, Kingdom of Bahrain, SMS group has successfully upgraded the motors and drives in the one-stand reversing hot rolling mill, originally built by a third-party rolling mill supplier. This project marks a significant milestone for both companies and aims to enhance the mill’s operational efficiency and reliability while equipping it to meet future demands in the aluminum processing sector.

The scope of the project included the replacement of outdated DC motors with three-phase AC motors and state-of-the-art drive technology, including variable frequency drive systems powered by active front ends and new transformers. The novel drive system, built to deliver 20 percent higher torque compared to the mill’s original design capacity, has restored GARMCO’s hot rolling mill to full operational capacity and positioned it as a future-ready facility capable of advancing research and development in aluminum hot rolling.

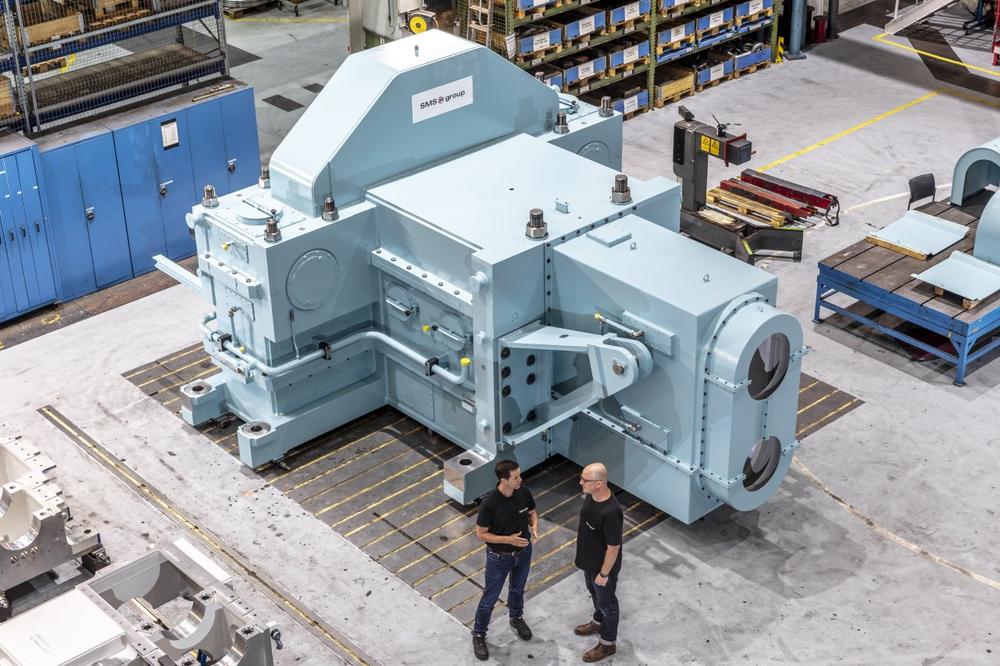

Central to the modernization was SMS’s cutting-edge twin-motor drive train equipment. Key components included a tailored gearbox for combining two electric motors with a rated power of 2150 kilowatts each and two SMS giant torque spindles. Combined with SMS’s highly advanced gear design, this drive train concept provides unique power capabilities and significantly reduces both investment costs and space requirements, while allowing for some degree of redundancy. In addition to the two main motors for the mill, SMS also supplied the X-Pact® Drive low-voltage frequency converter for the entry and exit coilers, a medium-voltage converter operated in load share mode, as well as transformers to feed the new systems. The equipment is tailored to meet the rigorous demands of GARMCO’s operations, which include the production of aluminum coils, tread plates, slit coils, and foils for diverse industrial applications such as packaging and heat exchange systems.

This successful collaboration was the first of its kind between both companies, with GARMCO choosing SMS group for its reputation for reliable, high-performance solutions boasting superior technical features and an optimized power factor. The new drive system guarantees enhanced torque capability over the entire speed range, a critical advantage for rolling operations requiring high torques at elevated speeds.

Commenting on the partnership, Ebrahim Khalil, Executive Manager Operations at GARMCO stated, “The completion of this modernization project is a testament to our commitment to maintaining world-class operational standards. SMS group’s expertise and advanced technological solutions have provided us with greater reliability and efficiency in our hot mill operations.”

The successful completion of this project underscores the strong ties between GARMCO and SMS. Over the years, SMS has supported GARMCO with technical services for its scalper machine, building a foundation of trust and collaboration. With this upgrade now complete, GARMCO’s hot rolling mill is poised to deliver sustained operational excellence, ensuring the production of high-quality aluminum products for its global customer base.

SMS group is renowned worldwide for its future-oriented technologies and outstanding service for the metals industry. The company applies its 150 years of experience and its digital know-how to provide the industry continuously with innovative products and processes – even beyond its core business – and generates worldwide sales of around 4 billion euros. SMS is the right partner for challenging projects and supports its customers throughout the lifecycle of their plants, enabling profitable and resource-efficient value creation chains. Paving the way for a carbon-neutral and sustainable metals industry is the company’s stated goal. As a global player with German roots, SMS takes responsibility for more than 13,500 employees.

SMS group GmbH

Am SMS Campus 1

41069 Mönchengladbach

Telefon: +49 2161 350-4449

http://www.sms-group.com

Corporate Communications and Marketing

E-Mail: thilo.sagermann@sms-group.com

![]()