- Radial forging machine: SMX 800 / 25 MN with 100 MN total press force enables direct conversion of ingots into billets and bars

- Next-level energy efficiency: Energy requirements reduced by 50 percent

- Patented “2+2 forging” strategy: Alternating of forging tool pairs to achieve targeted core deformation and controlled microstructural refinement in high-performance alloys

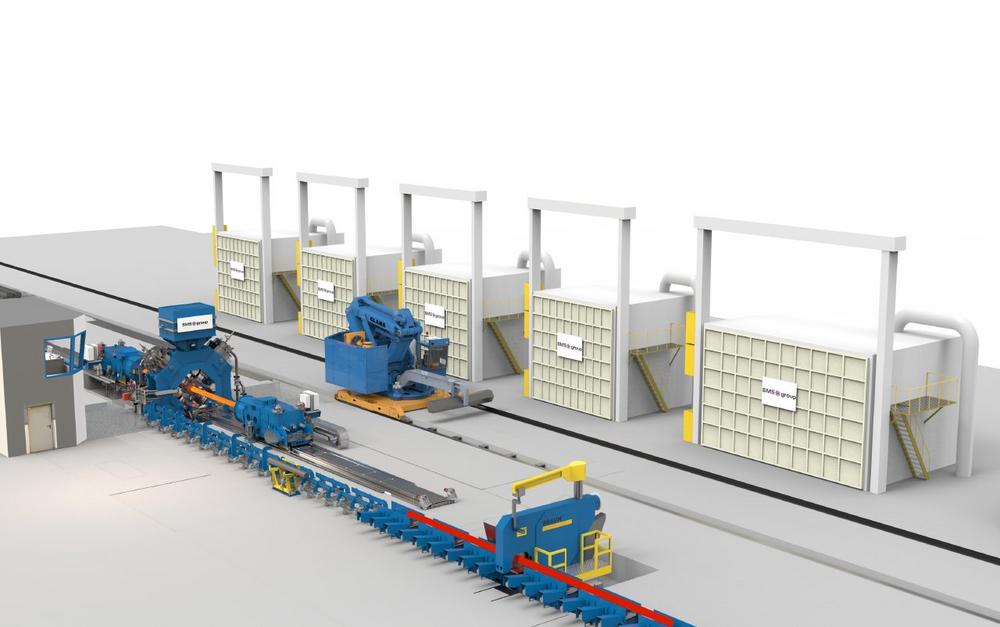

Haynes International Inc., a leading manufacturer of nickel‑ and cobalt‑based alloys, headquartered in Kokomo, Indiana and part of North American Stainless is a subsidiary of the Acerinox Group, and has commissioned SMS group to supply a powerful hydraulic radial forging line. The project includes the supply of the radial forging line from SMS group, comprising the SMX 800 / 25 MN hydraulic radial forging machine, reheating and annealing furnaces and quenching equipment. The line is completed by loading robot, cutting, unloading and bar finishing equipment providing a fully integrated, automated solution for high performance alloy component production.

The new plant investment will also include a vacuum induction melting facility and is part of Acerinox Group’s strategy to expand its global footprint in high-performance alloys.

Haynes International Inc. is part of North American Stainless, a subsidiary of the Acerinox Group. With its new hydraulic radial forging line, Haynes, together with North American Stainless, is expanding its production capability to serve demanding end markets such as aerospace and chemical processing in the United States. The project is scheduled for completion in 2027.

The SMX 800 / 25 MN is a powerful radial forging machine and will deliver 25 MN per forging cylinder, providing a combined total of 100 MN pressing force. This corresponds to approximately 11,240 short tons of pressing force and enables the direct conversion of ingots into billets and bars for aerospace and other high-performance applications.

At the heart of SMX hydraulic radial forging technology is a hydraulic drive system that integrates essential components into a compact, preassembled unit to reduce spatial requirements and improve energy efficiency. Incorporating latest developments, the new SMX hydraulic radial forging machine reduces installed electrical power requirements by about 50 percent and peak power demand by about 60 percent. These savings are achieved while preserving the hydraulic system’s core advantages, including constant pressing force, full process control and superior force stability. Hydraulic radial forging machines provide the required force over the entire stroke of the forging cylinder, enabling constant available force, precisely controllable forming speeds and high core deformation for effective void closure and reproducible microstructures.

SMS group’s modern reheating and annealing furnaces are specifically designed to achieve and control stock temperature in accordance with AMS 2750 tolerance and uniformity requirements. The furnaces will be equipped with low-NOx burners to ensure emissions remain consistently below the applicable EPA standards and will use an integrated recuperative system to enhance process efficiency.

Integrated with SMS group’s MIDIS production and control system, the forging line will orchestrate all production sequences and enable operator-free operation. Advanced software tools, including Comforge®, will be used to optimize forging strategies by adapting to actual material behavior, improving consistency and yield. Haynes’ ability to produce high-performance alloy products more efficiently and with superior metallurgical quality is increased.

Thomas Winterfeldt, Head of Forging Plants at SMS group, emphasizes the innovation behind the project: “We are proud to be building a high-performance hydraulic radial forging line for Haynes that shows our commitment to pushing the limits of capability and efficiency. The SMX hydraulic radial forging machine enables the forming of large, critical components for the aerospace industry.”

SMS group looks forward to continuing its long‑standing partnership with the Acerinox Group and North American Stainless as they expand capabilities in high‑performance alloy production with innovative hydraulic radial forging technology.

SMS group is renowned worldwide for its future-oriented technologies and outstanding service for the metals industry. The company applies its 150 years of experience and its digital know-how to provide the industry continuously with innovative products and processes – even beyond its core business – and generates worldwide sales of around 4 billion euros. SMS is the right partner for challenging projects and supports its customers throughout the lifecycle of their plants, enabling profitable and resource-efficient value creation chains. Paving the way for a carbon-neutral and sustainable metals industry is the company’s stated goal. As a global player with German roots, SMS takes responsibility for more than 13,500 employees.

SMS group GmbH

Am SMS Campus 1

41069 Mönchengladbach

Telefon: +49 2161 350-4449

http://www.sms-group.com

Fachpresse

Telefon: +49 2161 350-4449

E-Mail: thilo.sagermann@sms-group.com

![]()