Industrial practice soon shows how differently RFID labels react to their surroundings. Especially uses on glass, metal, or in ESD settings call for designs that have been precisely coordinated with those conditions. “Those challenging scenarios are particularly prone to showing the stability of a label’s design and the care invested in preparing it for its service in the field,” explains Natalia Biedulski, RFID product manager at SPT. “Standard solutions frequently reach their limits in those settings, whereas customized RFID systems are fully effective exactly where there’s a maximum need in the place where they’re deployed.”

RFID as a Strategic Process Element

Whether in water treatment, where users benefit from end-to-end documentation of maintenance processes and high system availability, or in special machinery engineering, where Item Match Control as a lock and key model prevents tampering with consumables: These examples illustrate how RFID becomes a strategic element of industrial processes. Many customers are currently faced with the question of how processes can be designed for automation and future viability. The decisive impetus is rarely on the individual RFID label per se but on the careful consideration of the entire process.

Process Stability and Security as Competitive Factors

In markets with narrow margins, the stability of processes often determines a company’s competitiveness. Businesses that deploy RFID with pinpoint accuracy and in line with their requirements achieve higher levels of machine availability and fewer downtimes that clearly translate into competitive advantages. To ensure that applications not only function reliably but are also secure, Schreiner ProTech integrates the utilization of Hardware Security Modules in the production process. They offer protection against attacks and ensure that every RFID identity is generated, stored, and processed in tamper-proof ways. That provides customers not only with a label but with a protected total solution.

Prospects for Data-Based Industrial Processes

In the coming years, the precise availability of data will be a crucial factor for resilient industrial processes. That’s why the product portfolio of standard RFID solutions has been revised and is now available in a new generation featuring the powerful UCODE9 chip family. Anyone interested in learning more about the potential of the RFID-DistaFerr product family or the Robust-RFID technology can obtain information at the AIM booth in Hall 2, Stand 2B05 and experience how forward-looking solutions are being developed for industry with high technical expertise and a strong vision.

About Schreiner ProTech

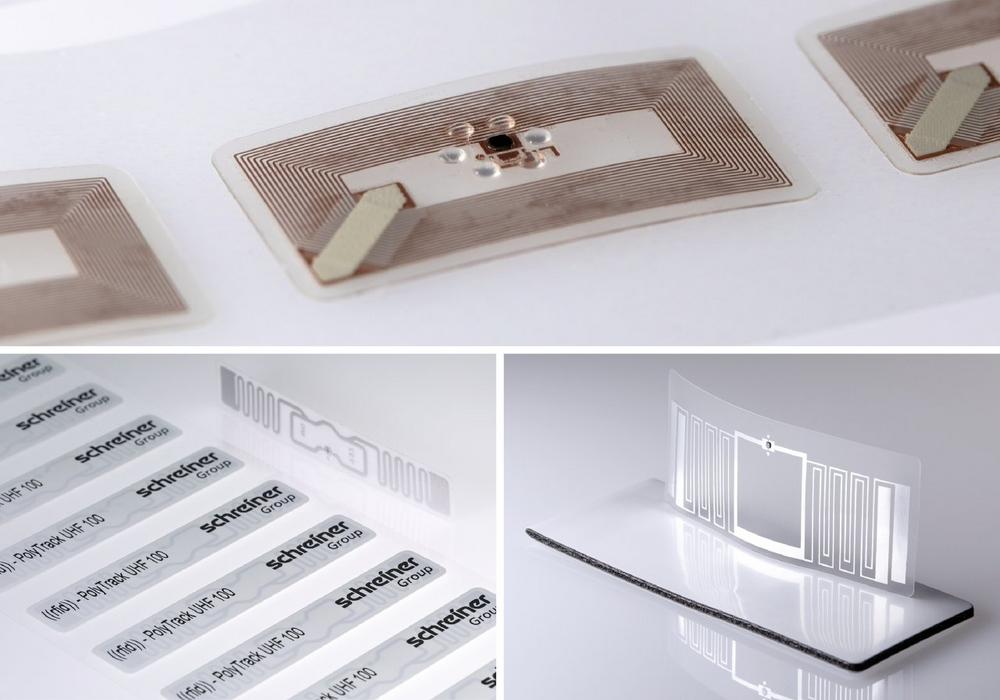

Schreiner ProTech, a business unit of Schreiner Group GmbH & Co. KG based in Oberschleissheim near Munich (Germany) and production sites in Blauvelt (USA) and Shanghai (China), develops innovative film-based functional components and industrial marking and security solutions. From thermal-transfer printing, laser marking and RFID solutions all the way to pressure compensation seals and printed electronics: the certified development partner and systems supplier offers solutions which help optimize processes, reduce costs, make life healthier and safer, and enhance human mobility. All of Schreiner ProTech’s solutions for the mobility and electronics markets as well as for mechanical engineering are specifically tailored to meet customers’ needs.

Schreiner Group GmbH & Co. KG

Bruckmannring 22

85764 Oberschleißheim

Telefon: +49 (89) 31584-0

Telefax: +49 (89) 31584-5166

http://www.schreiner-group.com

Produktkommunikation

Telefon: +49 (89) 31584-5517

E-Mail: iris.cuntze@schreiner-group.com

![]()