Applications of Gas Analysis

Environmental Monitoring

Gas analysis is vital for environmental applications, enabling the quantification of greenhouse gas (GHG) emissions and their geographical distribution. Industries such as agriculture, manufacturing, and transportation rely on accurate gas measurements to assess their impact on climate change and comply with environmental regulations.

Medical Diagnostics

In the medical field, precise gas analysis is indispensable. A prominent example is capnography, a non-invasive technique that continuously measures carbon dioxide (CO2) concentration in a patient’s breath. This real-time data is critical for assessing ventilatory status, confirming endotracheal tube placement, and monitoring patients during sedation or anesthesia.

Process Analytical Technologies

In industrial settings, gas analysis is crucial for process monitoring and control, ensuring quality assurance, yield optimization, and regulatory compliance. The technologies utilized in this arena are collectively referred to as Process Analytical Technologies (PAT), which enhance operational efficiency and safety.

Advantages of Optical Gas Sensing

Absorption Spectroscopy

While several gas sensing technologies are available, optical technologies have some distinct advantages over the others. Optical gas sensing techniques rely on spectroscopy principles, using the unique absorption characteristics of gases for their quantification [Fig. 1]. These methods do not require consumables such as chemicals or adsorbents, resulting in high energy efficiency, long measurement life and low cost per test.

Furthermore, optical gas sensing technologies can be seamlessly integrated into automated systems used in applications that require continuous operation. In recent years, optical gas sensing technologies has seen a surge in popularity. This is due to advancements in light source and detector technologies operating in the near- and mid-infrared regions[2] (NIR and MIR) of the optical spectrum where gas absorption is strong.

Key Requirements for Optical Gas Sensing in Process Control

Choosing the right source or detector for optical gas sensing hinges on the application’s specific demands. For process control and monitoring – one of the most challenging gas sensing contexts – the following criteria are imperative:

High Sensitivity

Ability to detect trace gas concentrations.

High Selectivity

Accurate quantification of individual gases within complex mixtures.

Rapid Measurements

High throughput while maintaining accuracy.

Robustness

Reliability and accuracy maintained over extended periods.

Failure to meet these requirements can result in substantial losses, especially in large-scale

industrial operations that depend on reliable process control and monitoring. In scenarios involving toxic or polluting gases, non-compliance with emission regulations can lead to severe

penalties.

Quantum Cascade Lasers (QCLs) – an Ideal Solution

Quantum cascade lasers (QCLs) are some of the best MIR light sources for analytical applications.

These are small semiconductor lasers that can be operated in both continuous and pulsed modes.

Unlike most MIR sources, the linewidth of QCLs is extremely narrow (< 1 MHz), which is required for a high degree of spectral selectivity in applications like gas sensing, where absorption peaks in the MIR region are narrow. In a mixture of gases, the absorption bands of gases in a mixture often lie close together spectrally. To distinguish one from the other, narrow-linewidth light sources like QCLs are the appropriate choice.

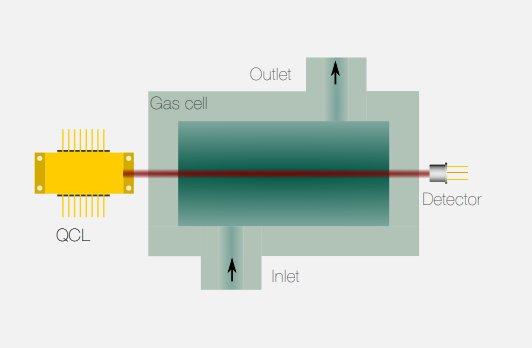

According to Beer-Lambert’s law, gas sensing uses absorption spectroscopy whose signal strength

depends on the concentration of the gas, light intensity, and the interaction path length [3]. Being

lasers, QCLs’ output can be easily collimated into a high-intensity beam, which is an advantage in

sensing low concentrations (a few parts per million). Moreover, the collimated beam also makes it easy to design multipass gas cells [Fig. 2], also known as Herriott cells. The purpose of Herriott cells is to increase the interaction path length. The more collimated a light source is, the easier it is to increase the number of passes in a Herriott cell, eventually heightening the sensitivity. Therefore, QCLs have a twofold advantage over non-laser-type MIR sources in terms of sensitivity.

Signal strength in absorption spectroscopy

∞ Conc of target gas × Intensity of light × Interaction path length

Enhanced Performance Features

The high sensitivity of QCL-based gas analysis, combined with fast, low-noise detectors, shortens

acquisition times. This enables frequent and precise measurements necessary for process control, a process dependent on input and output flow rates. When high gas flow rates are required, equally fast gas analysis methods are required for effective monitoring and control. QCLs’ fast response allows fast switching and high frequency modulation, further aiding high speed gas sensing.

Semiconductor Lasers –

Durability and Reliability

QCLs are robust semiconductor lasers. When coupled with an appropriate thermoelectric cooling mechanism and a low noise power supply, they maintain wavelength stability and operational efficiency under demanding conditions with little intervention. These factors make QCLs one of the best MIR sources for gas sensing in process control and monitoring.

Hamamatsu Photonics QCL Technology

With over a decade of experience, Hamamatsu Photonics has been providing quantum cascade

lasers (QCLs) for process control and monitoring applications. The company has continually

enhanced its QCL product line, offering improved packaging options, compact sizes, integrated

thermoelectric cooling mechanisms, and a variety of wavelength selections. While a limited set of QCL wavelengths is listed online [4], custom options between 4-12 µm are available on request.

Additionally, Hamamatsu offers a diverse selection of RoHS-compliant mid-infrared (MIR) detectors [5] available in various packages and spectral ranges.

Hamamatsu stands out for its commitment to developing QCL technology and accompanying MIR

detection solutions. For further inquiries regarding custom wavelengths or product specifications,

please contact Hamamatsu’s team of experts[6] or email info@hamamatsu.eu

Further details available here: Hamamatsu QCL Products

References

[1] https://www.hamamatsu.com/…

[2] https://www.hamamatsu.com/…

[3] https://www.sciencefacts.net/…

[4] https://www.hamamatsu.com/…

[5] https://www.hamamatsu.com/…

[6] https://www.hamamatsu.com/…

Hamamatsu Photonics ist der japanische Hersteller für optoelektronische Detektoren, Lichtquellen und Systeme. Das Unternehmen wurde 1953 in der Stadt Hamamatsu City gegründet und hat bis heute dort seinen Standort für Forschung und Produktion.

Hamamatsu Photonics zählt weltweit zu den Innovationsführern in der Photonik; entwickelt und produziert Komponenten auf der gesamten Bandbreite lichtbasierter Technologien und ist führender Hightech-Zulieferer für verschiedenste Industrien wie: chemische Analytik, Medizin-, Automobil-, Sicherheits- oder Röntgentechnik sowie Sensorik.

Im Bereich Systeme werden eine breite Palette von Bildverarbeitungssystemen hergestellt, die in Life Sciences, der digitalen Pathologie, der Halbleiterfertigung, der Prozesskontrolle als auch der Grundlagenforschung ihre Anwendung finden.

Die seit 1986 in Herrsching am Ammersee ansässige Hamamatsu Photonics Deutschland GmbH, beschäftigt mehr als 100 Mitarbeiterinnen und Mitarbeitern und betreut neben Deutschland auch die Länder: Bulgarien, Dänemark, Griechenland, Israel, Kroatien, Montenegro, Niederlande, Österreich, Polen, Rumänien, Slowakei, die Tschechische Republik, Türkei sowie Ungarn.

Geschäftsführer ist Dr. Reinhold Guth.

Hamamatsu Photonics Deutschland GmbH

Arzberger Str. 10

82211 Herrsching am Ammersee

Telefon: +49 (8152) 375-0

Telefax: +49 (8152) 375-199

http://www.hamamatsu.com

Public Relations

Telefon: +49 (8152) 375-171

Fax: +49 (8152) 375-111

E-Mail: pgenitheim@hamamatsu.de

![]()