What does it take?

The following Siemens technologies were used to set up the digital twin of HEKUdish GEN 2 and put it into virtual operation: S7-PLCSIM advanced was opted for to create and simulate the S7-1500 CPU. Connected by way of an interface to the SIMIT simulation platform and NX Mechatronics Concept Designer (MCD), this technology package can be used to create a comprehensive simulation environment. The MCD transfers the hardware with all physical information, i.e., fully kinematized, to the simulation. Before any real hardware is available, its functionality can be fully tested and the machine behavior validated. "A major benefit was the fact that we were also able to commission the interfaces of HEKUdish GEN 2 to third-party equipment, such as the injection molding machine, and test them upstream. This is precisely what takes up a lot of time and incurs costs in real-world commissioning," as Christoph Behner, Director of Operations at BBS in Hallbergmoos, relates. SIMATIC WinCC Unified was also selected for the new user interfaces on large panels.

What was the result?

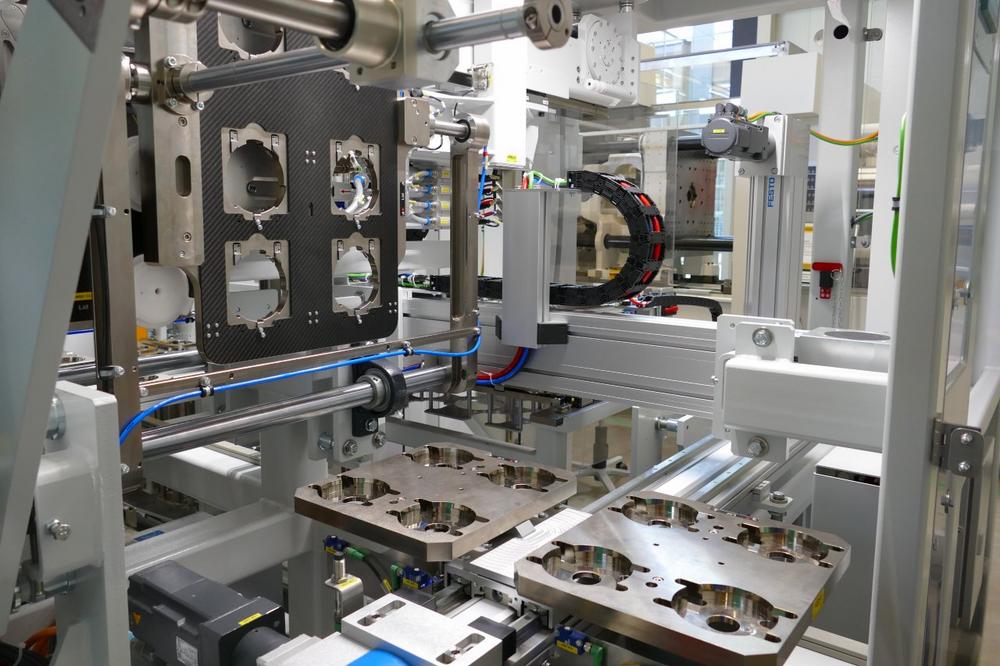

Markus Schmidt, CEO of BBS Automation Hallbergmoos, briefly explains the fundamental strengths of BBS solutions at the Hallbergmoos site: "Our systems are utilized wherever small, complex parts have to be taken out from injection molding tools with many cavities. In the process, we achieve very short mold opening times." The new HEKUdish GEN 2 is a machine platform that, in contrast to the previous concept, takes out Petri dishes and Contact dishes from injection molding tools and performs all the further processing steps, i.e., the assembly of lids and bases, stacking, as well as the subsequent vacuum sealing and packaging of the dishes. Compared to the previous concept, the innovative feature here is that it can be used for both the production of Petri dishes and Contact dishes right from the outset by way of a simple changeover. Even the handling of different product configurations, such as different dish diameters, is possible. In addition to this high degree of flexibility, the machine also focuses on further reducing cycle times and boosting technical availability – which is why the latest motor, drive, and control technology from Siemens was opted for. "Due to the short time frame until delivery and the extensive technology we were using for the first time, virtual commissioning was really important for us in order to set everything up, gain experience, and reduce risks in the course of engineering," says Behner.

How did you get there?

In the course of the digitalized engineering of the HEKUdish GEN 2, a multitude of tasks were performed in parallel rather than sequentially – which raised questions within the team. For example: Writing software without a circuit diagram? Motions without existing mechanics? The digital approach makes assumptions for these and other aspects.

The commissioning team did not have to wait for the machine to be set up on the shop floor, which meant that a lot of things became apparent at a very early juncture: "For example, what influence a particular sensor has, how it should be adjusted, and whether it is even accessible to the commissioning team," explains Fischer. "This gave rise to many ‚aha‘ moments, which once again underlines the fact that the digital twin is far more than merely a 3D animation."

Together with the machine platform, entirely new software was written, including a safety structure integrated into the Siemens control system – and also pre-validated on the digital twin. Knowing that the software works as intended by risk assessment increases confidence in the hardware commissioning, which is restricted to the validation of real processes. The activities that previously had to be carried out in the assembly hall on tied-up capital were reduced to the absolute minimum.

And how did it all work out?

Fischer emphasizes the smooth and seamless cooperation with the Siemens team, which actively participated in the digital implementation of the machine: "We needed this support plain and simple because we lacked the time and expertise. And regardless of what issues we encountered, whether simple or complex, everything was solved and always in a timely manner." This also allowed the BBS team to gain experience. Whenever something was discovered on the digital twin, it could be presented to the Siemens team and confirmed or refuted. "We received the most support, however, in the MCD area, i.e., the kinematics of the CAD involved, where we were really breaking new ground," explains Fischer.

What‘s next on the agenda?

BBS has decided to continue along the digitalized engineering course. There are increments, however, between "all or nothing." That is why a decision matrix is being developed addressing questions about the project’s risk potential and the benefits of digitalization. This leads on to three different outcomes, which Fischer explains as follows: "Firstly, a complete twin with physics is created, i.e., with kinematics. Secondly, a twin without physics is created, which we use to simulate the software, but without involving motion. In this case, you should already be familiar with the machine, for example, as in the case of a repeatable system. And thirdly, there is no simulation in the case of our simpler machines for example."

What are the benefits?

Using the example of the HEKUdish GEN 2 development project, the project duration was reduced by approximately 25 percent by comparison with the conventional approach. The search for the underlying reason leads to interesting conclusions: it wasn’t that less work was involved, but rather the advantages resulting from parallelization that proved decisive. In particular, the resources required for hardware commissioning were reduced due to software commissioning being brought forward. "Ultimately, our customers will also benefit tremendously from faster delivery times," says Schmidt, coming full circle on direct customer benefits.

And looking even further into the future?

The question of the benefits of the digital twin, however, can be viewed even more comprehensively. With fully parameterized, configured devices, ready-to-run hardware configurations, written function and software modules – all of which are stored in the TIA portal database for reuse and further development. This has resulted in many ideas for new business models delivering genuine added value. For example, in responding to typical customer requests: In order to automatically take out and process new parts produced with an existing machine, exchange sets are required. The conversion of the machines often involves software changes – which could be tested in advance on the digital twin, so that the machine is back in production more quickly. "If a customer knows that they will need exchange sets in the future, we could offer them the digital twin directly upfront, arguing that it will reduce their downtime and that the machine will be productive right from day one because training would also be carried out in advance on the digital twin," as Schmidt relates, describing one of several business models being discussed.

BBS Automation, a leading automation provider with 2,500 employees in 20 sites worldwide, offers a broad range of solutions, including assembly & test, winding, insertion and take-out technology, feeder & palletizing systems. Serving mobility, medtech, consumer goods, new energy, & electronics industries, BBS delivers solutions from a single source. BBS has sites in Europe, North America & Asia. Since 2023, BBS has been part of the Dürr Group.

The BBS site in Hallbergmoos, with approximately 200 employees, specializes in insertion and take-out technology in and from injection molding machines and the associated requirements for complex production processes with the highest quality and overall system availability.

BBS Automation Hallbergmoos GmbH

Dornierstr. 14

85399 Hallbergmoos

Telefon: +49 (811) 999 77 0

http://www.bbsautomation.com

Senior Marketing Manager

Telefon: +49 (811) 999 77 301

E-Mail: maria.goetz@bbsautomation.com

![]()