The AI breakthrough is based on the improvement of the algorithms and neural networks, that allowed for more parallel processes and so more scalable training on larger data volumes. More data equals better models. The growing adoption, the parallelization and need for large amounts of data inference leads us to the projected power demand growth of 165 % by 2030 [source].

These AI data centers work fundamentally differently than ordinary cloud services: the term AI factory is a new term that is thrown around. Instead of CPUs saving or loading cat pictures, GPUs either train, infer or generate according to prompts. The basic workload can be broken down into tokens, basic input and outputs of an AI model. The processing speed and efficiency of the tokens is key to the economic performance of the data center and like many processes, there are economies of scale prevalent. For this reason, chip producers are pushing the processing power of the GPU racks into the MW range. Considering that a “normal” rack uses around 20 kW, this is power increase requires a total overhaul and rethinking of the data center architecture for the power supply.

Why 800 VDC is the New Basis for AI Factories

Supplying 20 kW with standard three-phase low-voltage AC is straightforward and widely practiced. However, delivering 1 MW at low voltage is simply not feasible. Cable cross-sections become too large, the systems too heavy, and the infrastructure too costly. In addition, IT hardware ultimately runs on DC, so rectification is required, further increasing size, losses, and expense. Although the concept of DC-based data centers dates back to the early 2000s and several have been built. The high rack powers of today are pushing data-center designers and hyperscalers to reconsider it.

An 800 V DC rack architecture is being investigated, operating either at 800 V or ±400 V. The higher voltage reduces the required current, and DC systems inherently exhibit lower effective resistance than AC systems due to the absence of the skin effect. As a result, less copper is needed for power distribution. Major hardware manufacturers are developing power shelves that step down the 800 V supply to hardware-level voltages such as 48 V. This approach reduces copper usage, increases efficiency, and simplifies the overall system.

The 800 V rack addresses the question of how power will reach the rack, but the design of the distribution system remains unclear. Typically, operating voltage is increased to deliver more power; however, bringing medium voltage into a data center creates additional space and regulatory challenges. This is where superconductors come in.

Increasing Efficiency with High-Temperature Superconductors

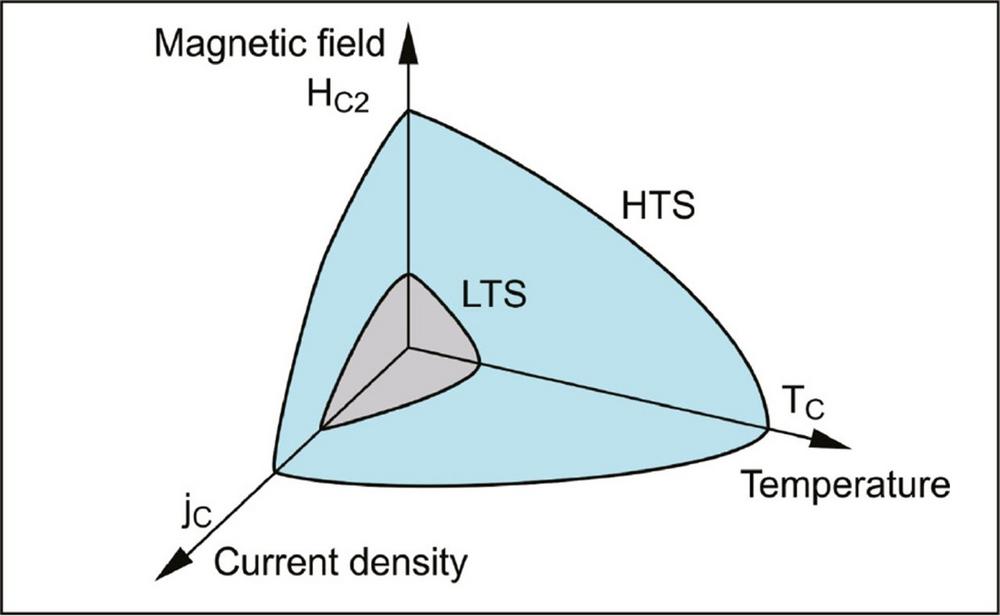

Superconductors don’t possess a DC electrical resistance. The current that can flow through them is dependent on the operating temperature and the magnetic field they are placed in. Due to the absence of electrical resistance and ability to carry extremely high current densities, superconductors make it entirely feasible to transmit megawatts of power at low voltage. 50 MW at 800 V would require an operating current of around 60 kA, a realistic current for superconductors.

To date, low-temperature superconductors (LTS) have been widely used in MRI systems, particle accelerators, and fusion reactors as high-field magnets. High-temperature superconductors (HTS) are replacing LTS now. HTS can be cooled with liquid nitrogen, making them much more economical, as liquid nitrogen is much cheaper and helium.

With growing industrial adoption, they are also beginning to replace conventional copper and aluminum conductors. High voltage HTS cables have been recently tested for a distribution grid application in Munich, Germany in the SuperLink project and last year currents up to 200 kA were demonstrated in an industrial environment in an aluminum plant for the Demo200 project.

In short: superconductors extend the advantages of the 800 VDC rack architecture all the way to the data center’s power distribution. Smaller, efficient conductors simplify the electrical infrastructure. The medium voltage distribution is exchanged for stainless-steel pipes (cryostats, 200 mm in diameter) that are thermally insulated and contain a liquid nitrogen circulation that keeps the conductors at operating temperature of around -200 °C. While decreasing the weight and size of the power distribution, operating costs are also reduced: 90% of the electrical losses are saved.

The main alternative to superconductors is water-cooled cables or busbars. Water can dissipate heat far more effectively than air, allowing these systems to operate at much higher current densities. It makes sense to use these for short distances inside a POD, bridging the distance between sidecar and rack, however, using them to distribute power in the data center is costly: much higher electrical losses and the need for active cooling to remove the additional generated heat.

At a current density of around 10 A/mm², a data center operating at 10 MW would incur nearly 1,000 kW of electrical losses for 100 m of water-cooled cables.

Using an HTS conductor, the electrical losses can be eliminated completely. Instead, only the heat leak into the system must be cooled away, around 1-2 W/m and the cooling for the initial current lead and sidecar terminations, around 100 W/kA in total for both. Also, no additional cooling is needed in the white space

What Superconductivity in the Data Center Looks Like

What does the superconducting system look like? A superconducting power distribution system is built around compact, extremely high-current conductors cooled to cryogenic temperatures. Figure 2 shows 8 pairs of HTS conductors inside a cryostat. Each conductor can carry up to 11 kA, enough to supply a POD with 10 MW, or 20 rack at 500 kW.

The inner and outer stainless-steel pipe make up the cryostat, the thermal insulation. Between the two pipes a vacuum in created to limit the heat transfer. Inside the inner tube liquid nitrogen is circulated, with a temperature range of 68 to 77 K (-205 to -196 °C). It absorbs the heat entering the system from the outside.

At each end of the system, termination units interface with the rectifier on the input side and the POD sidecar on the output side. These terminations cool the conductors and provide the electrical and mechanical connection to the rest of the power infrastructure.

The technology is currently being engineered, with several components such as the sidecar terminations, DC-DC converters, and protection systems requiring further optimization. Vision Electric Super Conductors is actively developing the needed HTS-busbars, current leads and sidecar terminations. Thanks to industry groups such as Current/OS and the Open DC Alliance (ODCA), direct-current applications are becoming better developed, more widely understood, and increasingly adopted. The Open Compute Project is also advancing 800 VDC system components and standards that will accelerate DC power distribution.

Energy Savings on a Massive Scale

While the superconducting system is more complex than its copper-based counterpart, it compensates with lower operational costs, fewer voltage transformations, and significantly more space-efficient conductors. For the data-center industry, the potential energy savings are substantial: even a 5% reduction in installed power translated into gigawatts saved across the globe.

However, before widespread adoption, data-center operators must be fully convinced of the reliability of cryogenic systems. In an industry driven by redundancy, uptime, and strict outage targets, reliability matters more than efficiency.

Future trends point toward HTS as the conductor of choice. HTS tapes continue to decrease in cost while improving in performance and current-carrying capability. In contrast, copper prices have been rising steadily and are expected to rise further as global demand for electrical infrastructure grows. Given the economic advantages and the trend toward ever-higher power densities, the question is no longer if superconductors will be adopted, but when.

Vision Electric Super Conductors GmbH (VESC), Kaiserslautern, Germany, founded in 2013, develops superconducting busbar systems for trasmisson of electricity at high power and low voltage levels.

Our vision is to use superconducting power transport systems to accelerate the electrification of the world to a higher and more efficient level. Superconductors contribute to a sustainable environment for us and future generations.

Our solutions complement conventional high-current busbar technology. VESC focuses on application projects with special requirements on busbar systems and cables, in terms of energy efficiency , construction effort and personal protection. The company’s founder, Dr. Wolfgang Reiser, is one of the recognized experts in high-current supply systems with global project experience and was founder and co-owner of of the technology companies for high-current applications, Vision Electric GmbH and EMS Elektro Metall Schwanenmühle GmbH.

Vision Electric Super Conductors GmbH

Morlauterer Str. 21

67657 Kaiserslautern

Telefon: +49 631 627983-0

Telefax: +49 631 627983-19

http://www.vesc-superbar.de/

Projektingenieur

Telefon: +49 (631) 627983-15

E-Mail: abrell@vesc-superbar.de

![]()