Every year, inVision awards prizes to ten particularly innovative or trend-setting products from the fields of image processing, embedded vision, and 3D metrology. An independent jury classifies these products and solutions as worthy of recognition for outstanding technical innovation, usability, and the potential to penetrate new market segments.

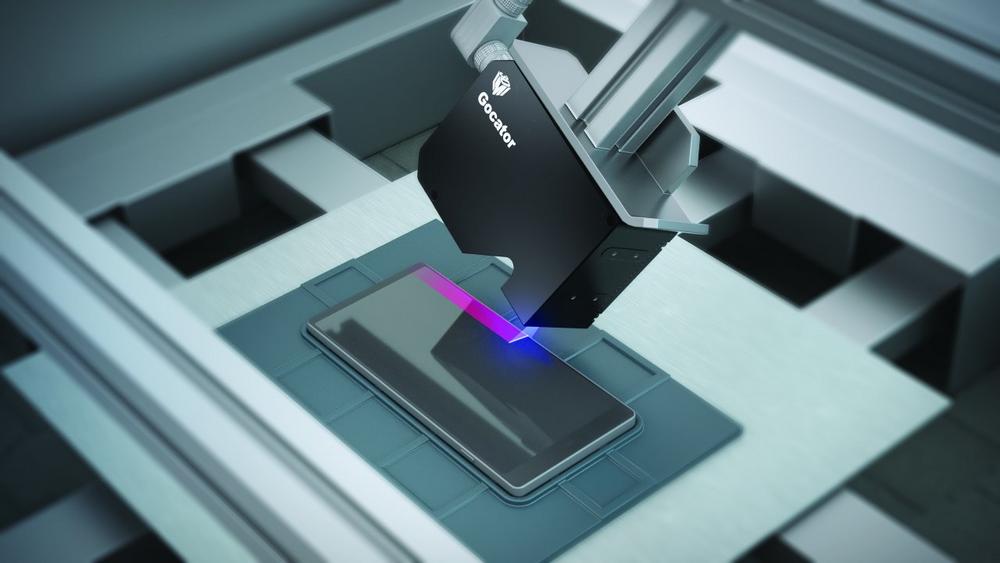

The Gocator 2512 sensor was chosen by jurors for its unique ability to scan specular and diffuse surfaces simultaneously. This is a valuable capability in cell phone display assembly inspection where different types of specular (i.e., reflective) materials are present. In this particular application, the 2512 sensor is able to generate a precision 3D scan of the cell phone display glass in a surrounding metal or plastic frame, then deliver robust measurement and inspection of critical assembly tolerances such as flushness, gap, and offset.

In addition, Gocator 2512 leverages specialized laser projection technology that gives the sensor the flexibility to handle a wide range of surface angles, material types, and surface colors, which helps manufacturers minimize system downtime and operational costs incurred by frequent production cell changeover.

“It’s an honour to have the Gocator 2512 recognized by a jury of discerning experts. This award gives us even greater motivation to develop smart 3D solutions that address specific customer needs. Congratulations to all the winners this year, and happy innovating in the year ahead!” said Terry Arden, CEO, LMI Technologies.

At LMI Technologies we work to advance quality and productivity with 3D sensor technology. Our award-winning, FactorySmart® laser, snapshot, and line confocal sensors improve the quality and efficiency of factory production by providing fast, accurate, reliable inspection solutions that leverage smart 3D technologies.

Unlike contact-based measurement or 2D vision, our products remove complexity and dramatically reduce implementation cost while achieving repeatable, highly accurate measurement results.

To learn more about how LMI’s inspection solutions can benefit your business, we invite you to contact us at contact@lmi3d.com or visit us at www.lmi3d.com to explore the possibilities of smart 3D technology.

About inVision

The trade journal inVISION (7th year, circulation 15.000 copies) covers topics in Machine Vision, Embedded Vision, and 3D inspection technology. In addition to the printed edition of 15.000 copies, inVISION is sent as an e-paper to more than 16.000 subscribers of the inVISION / VISION Newsletter.

inVISION is divided into the categories of cameras & interfaces, components, embedded vision & industrial PCs, and systems & applications, with a focus on highlighting the components and systems that are necessary to overcome current technical problems and inspection tasks. Visit www.invision-news.de to explore the InVision online magazine and download past issues.

LMI Technologies

Warthestraße 21

14513 Teltow

Telefon: +49 (3328) 9360-0

Telefax: +49 (3328) 305188

http://www.lmi3d.com

Regional Marketing Manager – EMEAR

Telefon: +49 (3328) 9360161

E-Mail: vgermann@lmi3d.com

![]()