Direct access to all relevant component information

Before the implementation of the design guidelines for die-casting tools in Strategic Parts Management, there were only links and references within the design to individual details and other documents. Now the design guidelines are available as a PDF document directly in PARTsolutions and links to the engineering data within Strategic Parts Management are possible. The design guidelines specify how the die-casting tools are to be designed and which parts to be used within the company group.

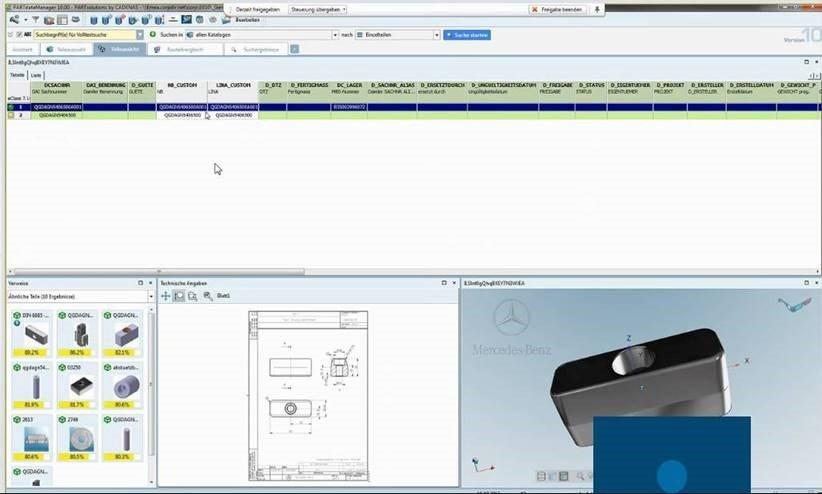

In addition, internal employees and engineers have direct access to 3D engineering data within the CADENAS solution, which can be inserted directly from the carmaker’s PDM system Smaragd into the respective designs in the CAD system NX.

Easier working conditions for external service providers

External service providers or suppliers also require access to on-going projects and internal standards. In the process, the respective engineering data must always be current. It must be clearly evident for external service providers, which standards are preferred in the designs. The supplier portal PARTcommunity Enterprise from CADENAS provides a direct connection for the customer to the Strategic Parts Management PARTsolutions and enables access to a great deal of parts information from the PDM system Smaragd and the ERP system SAP. External project participants therefore have access to all component information necessary for their designs via the online supplier portal. Any modifications in the construction lines are shown and are available to all participants. By simply enabling and disabling access for external service providers, the company can maintain control over the access to internal data.

The advantages of implementing the design guidelines for die-casting tools in PARTsolutions are obvious: The official guidelines are maintained in a central location and published automatically. Moreover, all the information about 3D engineering data as well as the respective 2D and 3D drawings are also available in one location.

CADENAS is a leading software developer in the areas of Strategic Parts Management and parts reduction (PARTsolutions), as well as Electronic Product Catalogs (eCATALOGsolutions). With its customized software solutions, the company acts as a link between the component manufacturers with their products and the purchasers.

With its 320 employees at 17 international subsidiaries, the name CADENAS (Spanish: process chains) has been standing for success, creativity, support and process optimization since 1992.

More information can be found on our homepage at: www.cadenas.de/en

CADENAS GmbH

Schernecker Str. 5

86167 Augsburg

Telefon: +49 (821) 258580-0

Telefax: +49 (821) 258580-999

http://www.cadenas.de

![]()