- Kögel Telematics: Two trailer telematics modules are available

- Transparency in the supply chain with Kögel Telematics

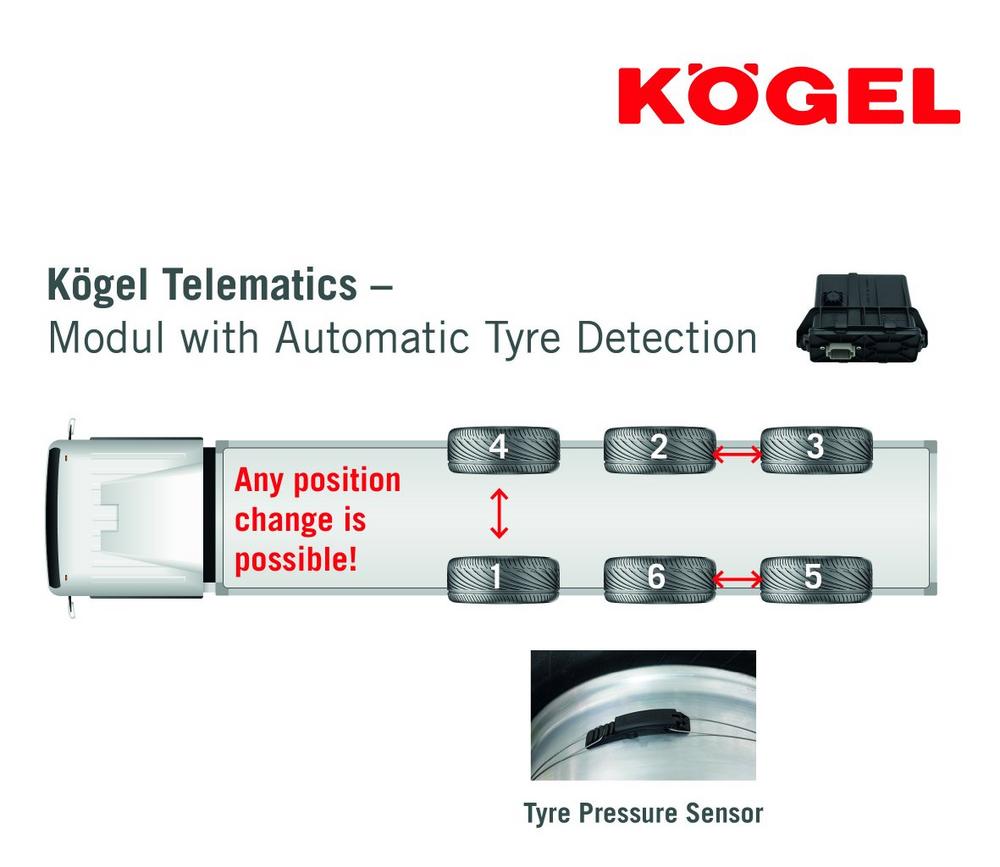

At Solutrans 2017, Kögel is presenting a new trailer telematics module with automatic tyre detection for the first time. This globally unique system automatically localises the tyre pressure monitoring sensors in each tyre. This means that tyres can be quickly and easily changed in any workshop. This is because there is no longer any need for the tedious and expensive manual sensor teaching process using software or special scanners, as required by previous systems.

From the second quarter of 2018, Kögel’s customers can therefore choose between two Kögel trailer telematics modules: either Kögel’s own trailer telematics module or the new trailer telematics module with automatic tyre detection, developed in co-operation with LDL Technology. Both modules are specially designed for systems coordinated with Kögel trailers and offer real-time access to trailer EBS, tracking, cooling, tyre and trailer data on a Kögel web portal that is clear, self-explanatory and easy to use.

Benefits of the new trailer telematics module with automatic tyre detection

The new Kögel trailer telematics module possesses an integrated tyre pressure monitoring receiver. This makes it possible to determine the exact position of every tyre pressure sensor, and thus every tyre. Kögel customers can therefore use any workshop to have their tyres changed, because the time-intensive and expensive teaching process of the tyre pressure sensors and reprogramming using special hand-held terminals are now a thing of the past. There is no need for the workshop employees to attend training courses and have software knowledge. The new trailer telematics module detects the tyre pressure sensors in the tyres and the position on the trailer automatically. This means that all the tyres equipped with a tyre pressure sensor can be replaced quickly and easily in the whole fleet. Naturally, this system also improves the reaction time in cases of pressure loss and reduces the risk of failure and accidents.

In conjunction with the EBS modulator and a cooling device, the new Kögel trailer telematics module with automatic tyre detection also supplies important data on the operating status of the trailer. The Kögel Telematics web portal can be used to evaluate this data as needed. It is also possible to define the geo-fencing in the Kögel telematics web portal and to set alarms that then notify the forwarder, the repair shop or the fleet manager, either by text or email, about defined deviations in the set parameters. The Kögel Telematics app, the Kögel web portal or the fleet management system can be used by forwarding companies to access the following real-time data in addition to the standard "PosControl" telematics data, such as locations, driving times and progress: "EBSControl" provides information from the electronic braking system (EBS) on items such as the braking response, mileage, speed, axle load, tyre pressure and brake wear. "TrailerControl" shows the current coupling status, the opening state of the doors and the battery status, as well as whether the ignition of the tractor unit is switched on or off. "TempControl" helps to monitor and control the temperature inside the refrigerated box vehicle and continuously monitors and documents the cooling chain, while also providing information about operating and service cycles.

Kögel Telematics is available for all vehicles in the Kögel product portfolio. Depending on the trailer type, there are various options for data transfer, optional hardware equipment and pricing.

Kögel Telematics is, of course, also available as a retrofit. This enables operators to retrofit vehicles that are already a part of their fleet with Kögel telematics.

Kögel is one of the leading trailer manufacturers in Europe. Since it was established in 1934, the company has manufactured more than 550,000 trailers. With its commercial vehicles and solutions for freight-forwarding companies and the construction industry, the company has been providing ‚Made in Germany‘ engineering quality for more than 80 years. During this period, it has maintained its passion for transport and innovation, enabling it to offer proven, long-lasting added value to freight-forwarding companies. The company headquarters and main production facility of Kögel Trailer GmbH & Co. KG are located in the Bavarian town of Burtenbach. Kögel also has factories and offices in Ulm (Germany), Duingen (Germany), Chocen (Czech Republic), Verona (Italy), Zwolle (Netherlands) and Moscow (Russia).

www.koegel.com

Kögel Trailer GmbH

Am Kögel-Werk 1

89349 Burtenbach

Telefon: +49 (8285) 88-0

Telefax: +49 (8285) 88-905

http://www.koegel.com

Leiter Öffentlichkeitsarbeit

Telefon: +49 (8285) 88-12301

Fax: +49 (8285) 8812284

E-Mail: patrick.wanner@koegel.com