BAUDIS IoT is the consistent enhancement of the BAUDIS diagnostic system developed by Baumüller, which has successfully been in use for more than 20 years. BAUDIS increases the process reliability and availability of production and is successfully used worldwide in machines and plants.

The BAUDIS IoT can be used independently of the manufacturer of the automation components and the sensors and therefore can easily be retrofitted and upgraded. It is therefore equally suitable for greenfield and brownfield plants, i.e. for the digitization of new and existing production facilities.

Intelligent Diagnostic and Communication System

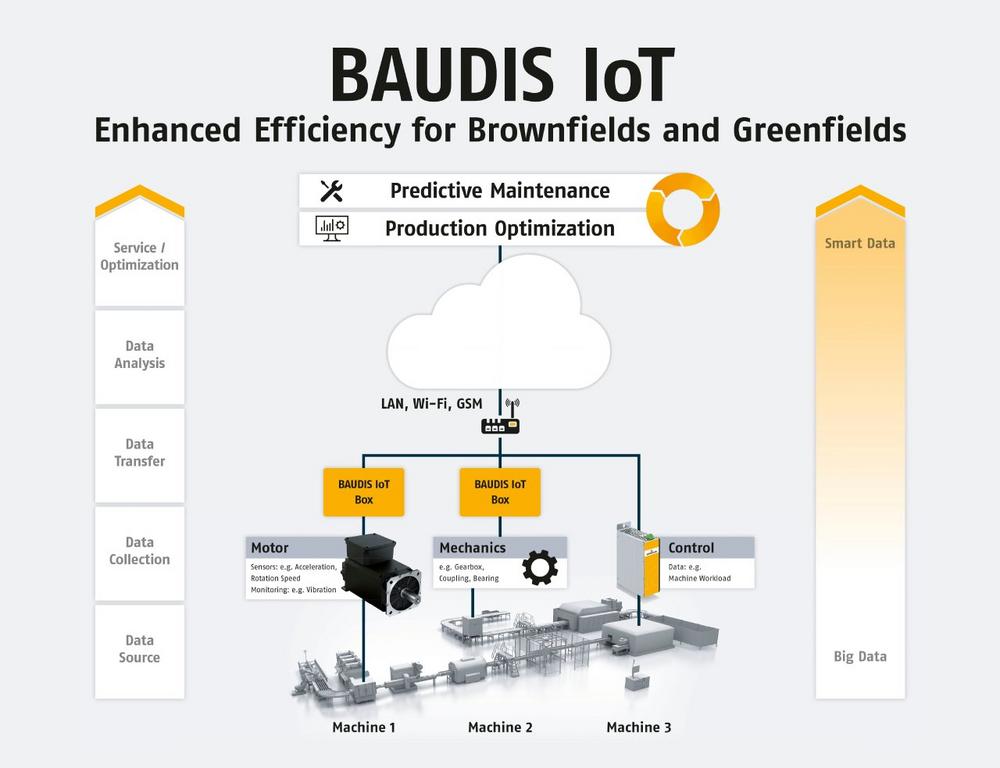

With brownfield plants, the networked system consists of sensors, a BAUDIS IoT box and an easy-to-use software with smart data algorithms. Data is recorded by local sensors on the drive or also on other electrical or mechanical components. For example these record the engine state, such as reporting resulting bearing damage or creating a vibration measurement, in order to detect wear on mechanical components at an early stage. The recorded data is collected in the BAUDIS IoT box with the Baumüller solution and is passed on to an evaluation unit. Subsequent recommendations for action are derived from this. With greenfield plants, the required data is read directly from the control system.

BAUDIS IoT from Baumüller allows for the continuous monitoring of automation components and machine states, data recording and analysis and the generation and output of a recommendation for action. The evaluation always occurs with the latest available algorithms. The system is thus continuously made more intelligent and uses algorithms to develop independent solutions (machine learning). By avoiding production errors, productivity increases and does so automatically through a self-regulating process.

Two versions for data archiving and evaluation

In principle, two versions for linking machines and systems are available. If the decision favors the local version, the data recorded on the drive will be evaluated directly by the operator on site. If the remote option is preferred, the data is uploaded to the cloud and is archived and analyzed either centrally at the customer’s location or externally at a service provider’s location for example. The benefits of the second version: The networking of plants and locations in the cloud or via a central server, i.e. an evaluation unit, allows for additional comparisons and evaluations. In addition, the updates can occur centrally. Externally, the evaluation always occurs with the latest available algorithms.

Smart data analysis saves time and money

Industry 4.0 applications create countless opportunities to improve machines, optimize drives, increase availability and make service more efficient. BAUDIS IoT is an industry 4.0 technology solution and provides for an intelligent networking of systems. With BAUDIS IoT, machine operators have an ideal system available to them in order to monitor their production and, in the event of a looming failure, to be able to act or react quickly or in a timely manner, thus increasing the running times of the machines and systems by means of scheduled maintenance measures. This saves time and money and improves the machine availability as well as the productivity. For the machine manufacturer, BAUDIS IoT is a good way to offer the system as an option and thus to create added value for his customers. Baumüller can completely take over the installation, monitoring and maintenance of the BAUDIS IoT system if desired.

Based in Nuremberg, Baumüller is a leading manufacturer of electric automation and drive systems. Around 1,800 employees are planning, developing, fabricating and installing intelligent system solutions for mechanical engineering and e-mobility at six production locations and 40 branches worldwide – from the user interface to motion control software as per PLCopen, software modules and controls all the way to converters, electric motors and the entire service program for automation solutions.

Baumüller’s full range of services also includes the areas of service, installation, assembly and relocation. Baumüller is one of the leading automation partners in mechanical engineering worldwide.

Baumüller Gruppe

Ostendstraße 80-90

90482 Nürnberg

Telefon: +49 (911) 5432-0

Telefax: +49 (911) 5432-130

http://www.baumueller.com

Marketing Communications Manager

Telefon: +49 (911) 5432-319

Fax: +49 (911) 5432-231

E-Mail: stefanie.lauterbach@baumueller.de

Ansprechpartner Presse

Telefon: +49 (911) 5432-549

E-Mail: susanne.reinhard@baumueller.de

![]()