Impact of surface finish

Generally the chip flow is dependent on surface smoothness. When the chips are able to flow better, there is less tailback on the cutting edge. This significantly reduces the pressure on the cutting edge. As the chips are removed from the chip groove more quickly, the chips are heated less. These positive effects of the smooth surface mean that higher cutting speeds and significantly longer tool life can be achieved. The smooth surface also reduces the risk of fusing with the material being machined. The polish enables higher cutting values and feed rates to be achieved.

Additional effect

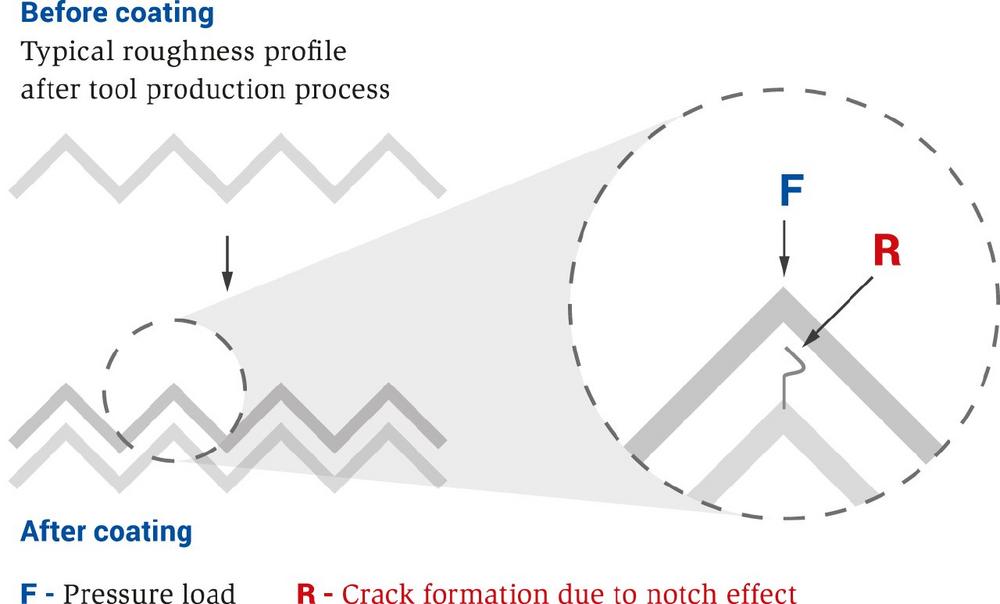

To increase the quality of cutting and forming tools, these are often coated with carbide layers. These are applied either in the PVD or CVD process. These coatings are intended to increase tool life and contribute to higher cutting speeds. The quality of these coatings depends largely on the surface finish, deburring condition and sharpness of the cutting edge. A rough surface with pointed contours increases the notch effect under load, leading to chipping of the hard material coating. (Figure 1) Coatings generally increase the roughness parameters. This is another reason why it is desirable to smooth the surface before coating. OTEC has developed a process in which these roughness peaks are rounded. This significantly improves the surface finish and considerably reduces the notch effect. (Figure 2) The OTEC process not only ensures a smooth, polished flute, but also improves the adhesion of coatings.

The surface treatment is carried out manually by the drag finishing process. The tools are clamped in special holders and dragged at high speed in circular motion through a container with grinding or polishing granulate. Due to the fast movement, a high contact pressure is generated between the workpiece and the processing medium, which achieves an optimum finishing result in the shortest possible time. The special dry polishing process produces a high gloss finish in the quality of a hand polish. For example, the surface roughness of an end mill can be reduced from Ra 0.31 µm to Ra 0.03 µm. The smooth surface provides ideal conditions for the subsequent coating and improves its adhesion. With minimal material removal, OTEC’s finishing processes are economical, technically advanced and achieve the best results. Depending on the requirements and production size, stream finishing systems with automation solutions can also be used for processing. OTEC offers the right machine technology not only for the polishing of hard metal workpieces, but also for the precise rounding of cutting edges of cutting tools.

OTEC Präzisionsfinish GmbH offers precise technology for perfect surface finish. OTEC machines for deburring, grinding, smoothing and polishing guarantee an efficient and perfect surface finish of tools and products. Operating a worldwide distribution network, OTEC is represented locally for international customers from various industries. Thousands of customers benefit from the extensive know-how of the technology leader OTEC in the development of a perfected interplay of machine and process media.

OTEC Präzisionsfinish GmbH

Heinrich-Hertz-Straße 24

75334 Straubenhardt

Telefon: +49 (7082) 4911-20

Telefax: +49 (7082) 4911-29

http://www.otec.de

Telefon: +49 (7082) 491120

Fax: +49 (7082) 4911142

E-Mail: m.mutter@otec.de

![]()