“The machine is specially geared towards lines with a low output,” explains Cornelius Adolf, labeling product manager at KHS. During development particular attention was paid to simple operation and a high degree of economy. The table machine is not only of interest to craft breweries but also to companies in the food sector, such as manufacturers of canned food, sauces or dressings.

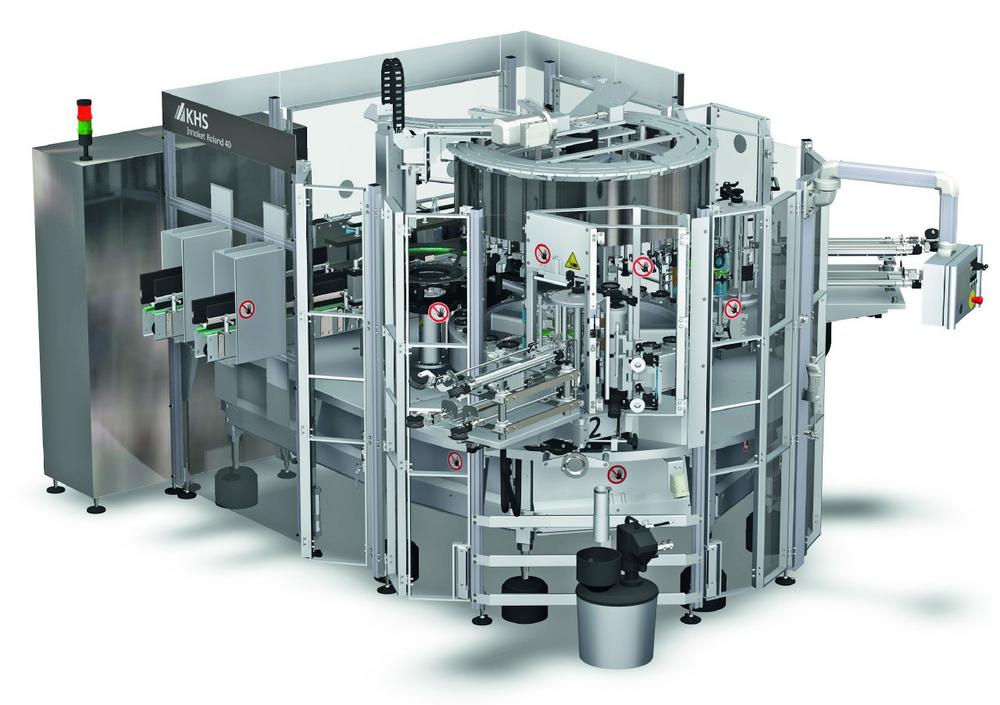

In its standard version the Innoket Roland 40 comes with two cold glue stations. This allows shoulder and neck labels to be applied at two levels by the first station, for instance, with the second station affixing back labels to the bottles. Alternatively, self-adhesive stations, a combination of cold glue and self-adhesive technology and hot melt labeling processes can be used.

Proven components from the high-capacity range

Inside the Innoket Roland 40 are countless quality-determining components taken from the established high-performance KHS Innoket Neo labeling machine. These include the carousel, infeed and discharge stars, folding doors, installation and format parts and guides and on the cold glue station the gripper cylinder and label magazine. The Innoket Neo servo feed screw has also been applied and integrated here, permitting gentle bottle stops.

Plenty of upwards scope

The KHS development also provides many different opportunities for extension to cater for individual labeling tasks. It is possible, for example, to equip the Innoket Roland 40 with the KHS VarioDrive electronic bottle plate control system. Other options include mechanical alignment by side notch in the infeed star and the fitting of traveling applicators, the latter used for cap or lid labels. U-shaped labels – as tamper-evident seals for twist-off caps, for instance – can also be labeled and rolled on. Optional sensors check for the presence of labels at certain points, for example in the label magazine or on the gluing roller, and for other factors such as broken bottles. With its many expansion options the KHS Innoket Roland 40 is thus perfectly suited to cater for all requirements in the low capacity range.

At Anuga FoodTec the Innoket Roland 40 demonstrates its perfect suitability for the food industry through its point of display alone. The technology can be viewed live not at the KHS booth but at Florin Gesellschaft für Lebensmitteltechnologie mbH at booth E20/F29 in hall 10.1 where the system designed for an output of 2,500 to 25,000 containers per hour will be exhibited.

KHS is one of the leading manufacturers of filling and packaging systems for the beverage, food and non-food industries. The KHS Group includes the following companies: KHS GmbH, KHS Corpoplast GmbH, NMP Systems GmbH and numerous subsidiaries outside Germany.

KHS GmbH manufactures modern filling and packaging systems for the high-capacity range at its headquarters in Dortmund, Germany, and at its factories in Bad Kreuznach, Kleve and Worms. The KHS Group’s PET expertise is pooled at KHS Corpoplast GmbH in Hamburg, Germany, where innovative PET packaging and coating systems are developed and produced. NMP Systems GmbH, a wholly-owned subsidiary of KHS GmbH based in Kleve in Germany, designs and markets new, resource-saving packaging systems for PET bottles.

In 2016 KHS and its 4,995 employees achieved a turnover of around €1.18 billion within the Salzgitter consolidation. The companies in the KHS Group are 100% subsidiaries of the MDAX-listed Salzgitter AG corporation.

KHS GmbH

Juchostr. 20

44143 Dortmund

Telefon: +49 (231) 569-0

Telefax: +49 (231) 569-1541

http://www.khs.com

Presse- und Öffentlichkeitsarbeit

Telefon: +49 (251) 62556121

Fax: +49 (251) 62556119

E-Mail: wopen@sputnik-agentur.de

![]()