Under the motto "Integrated Industry", an independent panel of experts consisting of professors, scientists, industry experts and journalists chose the “BEST OF” the best. What counts is the progress (novelty, product maturity and future orientation) as well as the economic, social, ecological and technological benefits of the submitted solutions.

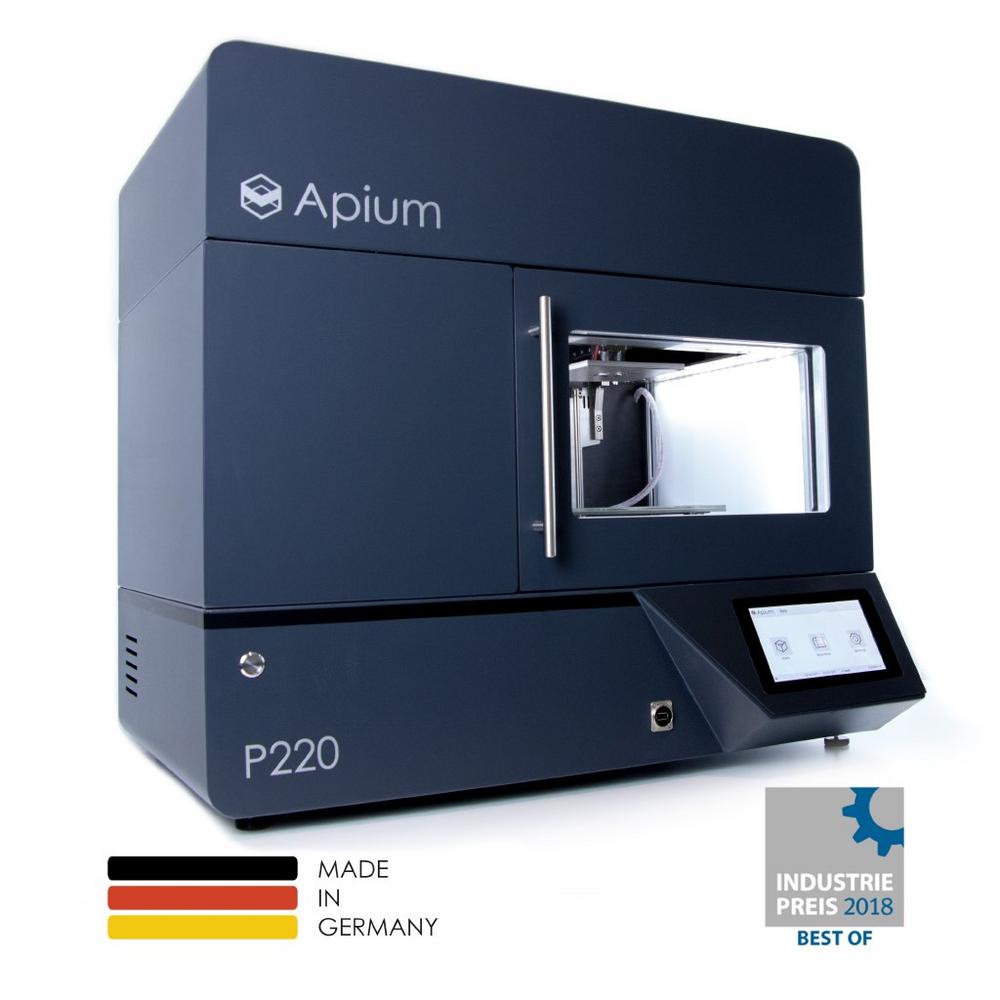

Apium received this special award for the category „Research and Development“ in recognition of "Apium P220 Series" 3D printers. With this high-end solution, we provide research groups, institutes, universities and schools in the emerging field of additive manufacturing (AM) with a unique tool for processing high performance polymers and composites. Already more than 25 universities and research institutes worldwide use the manufacturing potential of our advanced 3D printer to stay one-step ahead of the competition.

Apium P220 Series machines are equipped with high-quality closed-loop drive system and offer tailored solution for your choice of material and part geometry. This series of Apium 3D printers offer the unique ability to control the degree of crystallinity in parts 3D printed from semi-crystalline polymeric materials by regulating the melt to solid state transformation rate thus offering research and development groups a unique leverage on science and engineering at the manufacturing level.

"This special award fills us with pride and drives our ambition to continuously improve our research and development products as well as services and to make a significant contribution at positioning an innovative future" – Tony Tran-Mai, CEO of Apium Additive Technologies GmbH

We research, develop and produce Fused Filament Fabrication 3D printing filaments made from high performance polymers along with 3D printers to process them. After intensive research, we became the first company worldwide able to make PEEK (poly ether ether ketone) printable with the FFF 3D printing technology. As pioneers, we assure the best and most reliable print quality on the market. With our expertise and experience in practical applications, together with basic research, we have a unique competence center for small and medium enterprises from industries that use high performance polymers for the most demanding environments and applications.

With our strong core-competencies we strive to become the largest technology supplier of high performance filament materials and 3D printers for FFF 3D printing technology within the European market. Our goal is to set the industry standard in terms of quality and reliability at FFF 3D printing of high performance polymers. As a competence center we claim on the legitimacy to be present on the market and to take over a long-term leading role. Through our know-how and our expertise in the field of FFF 3D printing we assure our customers the highest quality and the best service.

Apium Additive Technologies GmbH

Siemensallee 84

76187 Karlsruhe

Telefon: +49 (721) 13 20 95 0

Telefax: +49 (721) 13 20 95 77

http://www.apiumtec.com/

Head of Marketing and Quality Management

Telefon: +49 (721) 6803087-0

E-Mail: pinar.karakas@apiumtec.com

![]()