OTEC offers a cost-effective process for the surface refinement of fashion jewellery and acces-sories: its disc finishing machines achieve the highest surface quality in the shortest possible time. The jewellery is polished to a high gloss, producing an impressively perfect finish. Compared with conventional processing in vibrators, the process times in OTEC disc finishing machines are consid-erably shorter and can produce better results. Depending on the workpiece size, shape and weight, surfaces can be good enough to go straight on sale.

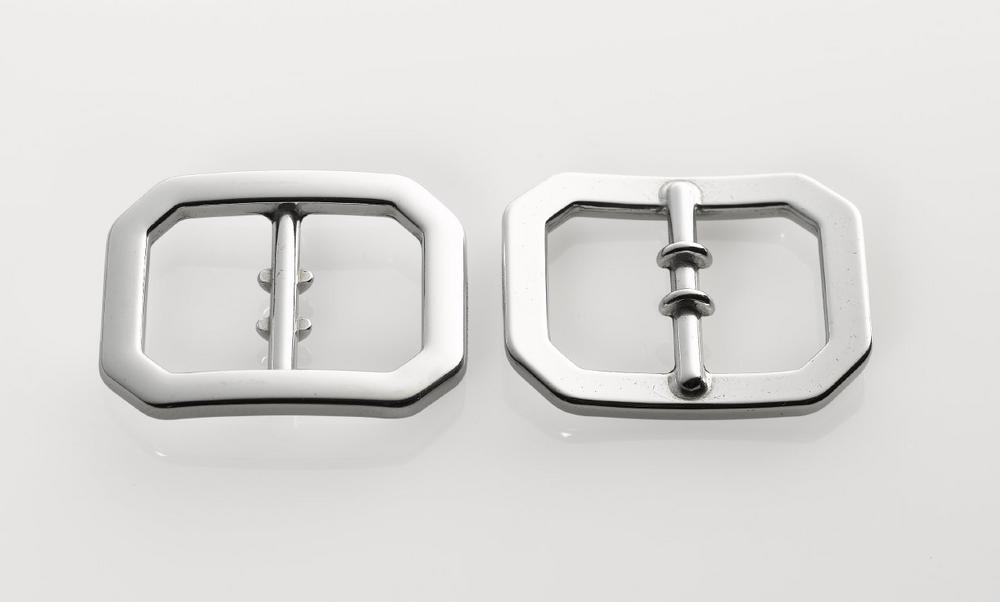

OTEC’s CF machine series uses a centrifugal process where workpieces are immersed in a rotating abrasive or polishing media turned by a revolving plate at the base of the process container, which is separated from the container wall by an adjustable gap. The various centrifugal forces make the processing highly intensive – up to twenty times more effective than conventional vibrators, for example. Achieving the perfect surface involves numerous process parameters, and for optimal results they must all interact correctly. OTEC has developed a process that is individually adapted to the piece of jewellery. For a very smooth surface, fashion jewellery such as decorative clasps, ornaments or belt buckles are usually finely ground with special plastic polishing media. The subse-quent wet polish ensures a flawlessly glossy finish.

For industrial jewellery production, the CF series disc finishing machines offer fast, reliable processing with the simplest handling. All the important process parameters such as speed, processing time, water-compound concentration and rinse cycles can be set and stored via a Siemens touchscreen control. With the optionally available dosing unit, the water and compound mixture can be automatically prepared and the dosing selected using the control system. This guarantees a stable process sequence for the reliable processing of costume jewellery. What’s more, the components used in the CF machines are just as reliable. Only high-quality materials and components ensure trouble-free operation and a long machine service life.

OTEC Präzisionsfinish GmbH offers precise technology for perfect surface finish. OTEC machines for deburring, grinding, smoothing and polishing guarantee an efficient and perfect surface finish of tools and products. Operating a worldwide distribution network, OTEC is represented locally for international customers from various industries. Thousands of customers benefit from the extensive know-how of the technology leader OTEC in the development of a perfected interplay of machine and process media.

OTEC Präzisionsfinish GmbH

Heinrich-Hertz-Straße 24

75334 Straubenhardt

Telefon: +49 (7082) 4911-20

Telefax: +49 (7082) 4911-29

http://www.otec.de

Marketing

Telefon: +49 (7082) 4911-20

E-Mail: info@otec.de

![]()