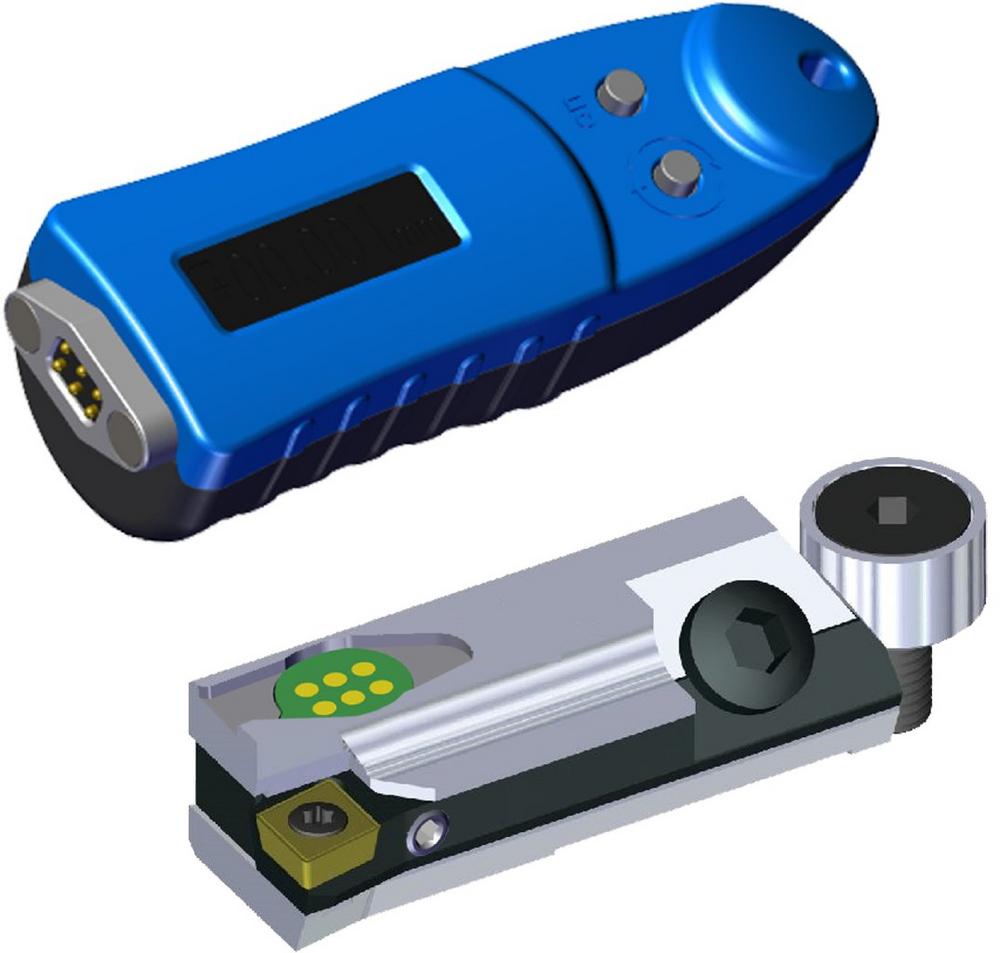

"Our digital precision drilling module saves users the legwork between the machine and the tool room," says Peter Heinemann, business manager of Tools at Swiss Tool Systems AG. The Swiss have developed a precision drilling module that can be set digitally, directly on the machine. It allows simple, fast and accurate length and diameter adjustments in the μ range and in ambient conditions. The adjustment is measured incrementally by means of a direct distance measuring system. That means, "there is no backlash," assures Heinemann. Radial adjustment for the plate position is 0.4 mm at the minimum. Axial length adjustment of up to 1.5 mm can be made via the wedge element. The new precision drilling module supports speeds of up to 10,000 rpm. The internal cooling system directs cooling lubricant directly down to the cutting edge.

An external display for precise values

Legwork to and from the tool room is no longer required. This is also due to the fact that values can be set accurately, and are displayed clearly and distinctively. Values are shown on an external display, which is docked when the adjustment procedure is performed. It houses the electronic evaluation module including the battery. The display can be docked to the port of the new precision drilling module by means of magnetic force. It displays adjustment values with an accuracy of 0.001 mm.

The external display is easy to operate. It can serve multiple precision drilling modules. The fact that the display can be rotated similar to tablets and smartphones makes it suitable for both right-handed and left-handed users. It can thus be read in a correct orientation at all times. It can also toggle between mm and inch. The vernier scale is often difficult to read, especially in precision drilling operations. The new digital precision drilling module by Swiss Tools makes this task significantly easier thanks to the reliable and error-free detection of set and changed values.

A leading name in its own right – and as an OEM

Founded in 1971, Swiss Tool Systems AG employs just under 50 employees in the manufacture of high-precision tool systems used in turning (HSK-T, PSC and KM), milling, and precision drilling. From its origins as a contract manufacturer of quality machine parts, the company has grown into a leading international producer of tools. Swiss Tool Systems AG now ranks as one of the key suppliers of all products used between the spindle and the blade edge. Swiss Flex, Swiss PSC, Swiss KM XMZ, Swiss Bore, Swiss Varia, Swiss MBM and Swiss CAD – our brands are known far beyond the borders of Switzerland. We also play an active role as an OEM for leading companies.

SWISS TOOL SYSTEMS AG

Wydenstrasse 28

CH8575 Bürglen

Telefon: +41 (71) 63485-20

Telefax: +41 (71) 63485-29

http://www.swisstools.org