As industrial processing complexity rises and the quality or safety-relevance of manufactured components increases, then even more applicable is the saying ‘time is money’. This fuels the need for processing solutions that raise productivity. Modern laser micro-machining methods are ideal for helping the electronics industry and other sectors to meet these challenges.

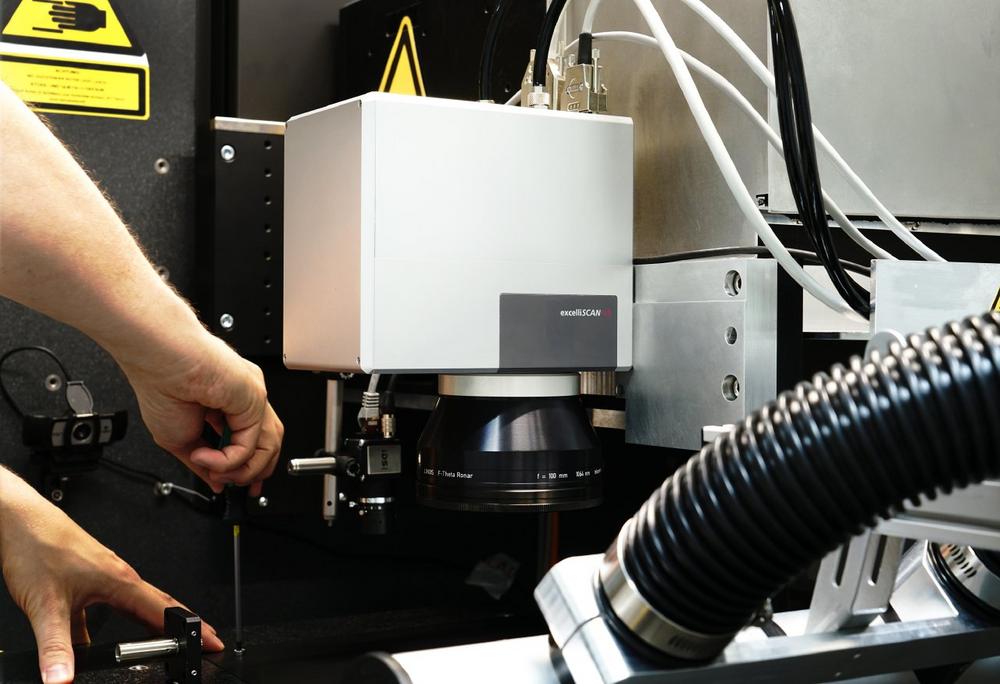

Extensive excelliSCAN test applications confirm that its unique servo design delivers considerable productivity gains for numerous applications. The scan system features novel SCANahead servo control as well as galvanometer scanners with highly precise digital angle sensors. And its in-built intelligence can be compared to autonomous driving – the scan head autonomously calculates its own control parameters and anticipates in real time for optimal navigation of curves. This servo innovation breaks through the irreconcilability between higher dynamics and maximum precision, and thus provides an appreciable productivity boost to users. Additionally, contour fidelity is substantially improved at high marking speeds, e.g. when traversing sharp corners and circles. Control is furnished as standard by the powerful RTC 6 control board, now available as an Ethernet variant.

Another element of the Smart Factory

And this premium scan system offers even more power for factories of the future. Integrated functions like online status monitoring or acquisition of operating times and process data allow not only integration in networked structures, but also retrospective process analysis.

"We’re very pleased with positive user feedback on the excelliSCAN. When applications have particularly challenging technical requirements, then our own standards for the applied technologies are likewise exceptionally rigorous," explains SCANLAB CEO Georg Hofner regarding the start of series production. "To secure future gains in maximum speed and precision, we’ll continue on the trajectory servo path we have embarked upon. The next step will involve planning trajectories."

In view of the strong demand for high-precision scan systems well-suited to micro-structuring and 3D printing, SCANLAB is already working to extend its excelliSCAN family: scan heads with 20 mm and 30 mm apertures are in the pipeline.

With over 30,000 systems produced annually, SCANLAB GmbH is the world-leading and independent OEM manufacturer of scan solutions for deflecting and positioning laser beams in three dimensions. Its exceptionally fast and precise high-performance galvanometer scanners, scan heads and scan systems find application in industrial materials processing and the electronics, food and beverage industries, as well as biotech and medical technology.

For more than 25 years, SCANLAB has secured its international technology leadership through pioneering developments in electronics, mechanics, optics and software, as well as the highest quality standards.

SCANLAB GmbH

Siemensstraße 2a

82178 Puchheim

Telefon: +49 (89) 800746-0

Telefax: +49 (89) 800746-199

http://www.scanlab.de/

Marketing & Kommunikation

Telefon: +49 (89) 800746-0

Fax: +49 (89) 800746-199

E-Mail: e.jubitz@scanlab.de