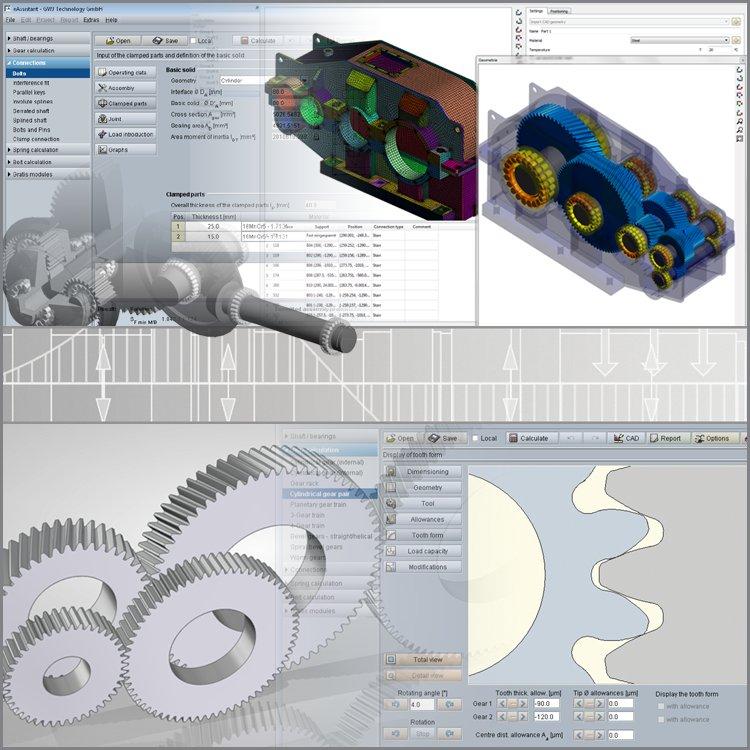

After several years of development, eAssistant was released in 2003 during Hannover Fair. Dial-up internet was literally the only kind of internet modem back then. The actual release was in May 2003 and included three calculation modules for shafts, rolling bearings and interference fits. The development process of the eAssistant continued thanks to the positive market response. Further modules for parallel keys, serrated and splined shaft connections as well as involute splines were added in 2003 and 2004. At the Hannover Fair 2005, the first version of the “Cylindrical gear pair“ was introduced. Even back then, this module already included the real gear tooth form based on a mathematical simulation of the manufacturing process. Based on this, the first 3D CAD plugins for SOLIDWORKS, Solid Edge and Autodesk Inventor were implemented shortly afterwards.

This was followed by the release of an English version and other gear modules. Single cylindrical gears, cylindrical gear pairs, planetary gear trains, three- and four-gear train systems, gear racks, bevel gears as well as worm gears can now be determined. eAssistant provides different standards in order to calculate the load capacity. DIN 3990 / ISO 6336 Method B or ANSI / AGMA 2101 are available. Calculation modules for bolted joints, timing belts, clamp connections and bolts and pins are also part of the eAssistant.

By the end of 2012, GWJ reached another major milestone – SystemManager, a true software application for complete systems of machine elements, was released. It runs as a classic desktop application, including FE libraries. The individual system elements are directly linked to the eAssistant calculation modules.

The software engineering process of eAssistant and SystemManager is heavily influenced by user feedback to improve the software quality. The applications are constantly being developed.

Visit www.gwj.de for more information or contact GWJ at +49 (0) 531 1293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology, a leading engineering company with its headquarter in Braunschweig, Germany, stands for high quality products and innovative software development. With keen insight, high energy and an enthusiastic team of engineers, we put our utmost efforts, skills, knowledge and passion into our work to achieve top quality products. Our portfolio includes the development of standard calculation software for machine elements, such as shafts, rolling bearings, cylindrical gears, bevel gears, etc. To increase the efficiency in the design process and to combine calculation and CAD, we provide CAD plugins for various 3D CAD systems. Our software solutions are designed with a sleek user interface, making it easier than ever to design or re-calculate machine elements. Additionally, we have geared our company to offer a special software application for the determination of real 3D tooth form geometries of complex gears. The tooth form is the basis for a 3D model to manufacture gears in conjunction with multi-axis machining centers. The software opens completely new possibilities for engineering.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

Geschäftsführer

Telefon: +49 (531) 1293990

Fax: +49 (531) 12939929

E-Mail: g.weser@gwj.de