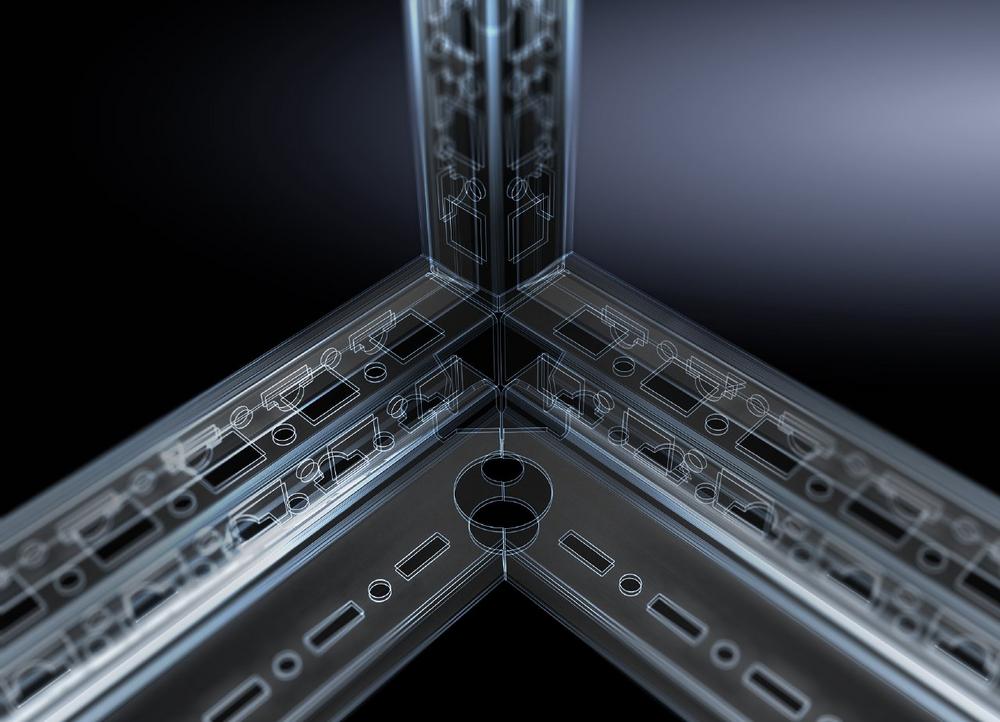

Control and switchgear manufacturers who want to increase their productivity and bring it in line with “Industry 4.0“ need all their data to be of the highest possible quality. The new Rittal VX25 large enclosure system supports control and switchgear engineering with complete, high-quality data for every process along its value chain – from electrical planning through mechanical design to manufacturing. A variety of web-based software tools are available from Rittal so that companies can quickly, easily and precisely convert to the new enclosure system.

Converting parts lists at speed

Parts lists from the earlier TS 8 enclosure system can now be easily turned into VX25 parts lists with the VX25 conversion assistant. TS 8 parts lists from projects that are to be used again need merely to be loaded into the conversion tool as an Excel file by drag and dop. If the Excel columns are selected based on model no and quantity, the user will receive the desired VX25 parts list with just one click. The program automatically displays items of no relevance for the VX25 in the list. Afterwards, the converted parts list can be simply downloaded or directly placed in the shopping cart for online ordering. TS 8 Model Nos can also be entered individually via a search field, and corresponding VX25 Model Nos and additional product information can be quickly found.

Besides this, plant constructors are also given support in converting from TS 8-based 3D enclosure layouts to VX25 system technology in EPLAN Pro Panel projects. The replacement of TS 8 enclosures and accessories for VX25 articles is largely automated.

Data for all common CAD systems

Rittal provides further help in converting to its new large enclosure system with the easy and free download of detailed, validated CAD data in more than 70 formats, enabling the flexible transmission of data to all common CAD systems. The EPLAN Data Portal can also be employed to load macros of the VX25 bayed enclosure system for mechatronic engineering using CAE/CAD and for generating 3D enclosure layout with EPLAN Pro Panel. Moreover, Rittal offers data for the VX25 for classification as per eClass (Advanced) and ETIM.

Selecting and configuring products with ease

With the VX25 selector, Rittal enclosures can be easily selected and the corresponding accessories found for appropriate applications. The enclosure types included can be populated to suit individual requirements with a pre-selection of common accessories.

The web-based configurator Rittal Configuration System enables simple and error-free configuration – even without prior CAD knowledge – of the VX25 and the desired installation components.

The tool permits the configuration of free-standing enclosures and bayed suites based on the VX25 – a task that is “plausibility checked”. For example, while accessories are being placed, the system will automatically check if the selected components can be placed at the chosen location. Machining can also be planned with the Rittal Configuration System since the configured data package not only contains the parts list but also a CNC program for the Perforex machining centre and a 3D step model of the complete enclosure including the accessories. This way, the data on the enclosure flows directly into the machining processes. The items configured can be ordered directly via the linked online shop, which makes the ordering process even easier.

Rittal, headquartered in Herborn, Germany, is a leading global provider of solutions for industrial enclosures, power distribution, climate control and IT infrastructure, as well as software and services. System solutions from Rittal can be found in more than 90 percent of all global branches of industry, including mechanical and plant engineering, food and beverages, IT and telecommunications.

The wide range of products from the global market leader includes configurable enclosures, whose data is available throughout the entire production process. Intelligent Rittal cooling solutions with up to 75 percent lower energy and CO2 consumption can communicate with the production environment and enable predictive maintenance and service concepts. Innovative IT solutions ranging from IT racks and modular data centres through to edge and hyperscale computing solutions all form part of the portfolio.

Leading software providers Eplan and Cideon complement the value chain, providing interdisciplinary engineering solutions, while Rittal Automation Systems offer automation systems for switchgear engineering. Rittal delivers within 24 hours in Germany – precisely as needed, flexibly and efficiently.

Founded in Herborn in 1961, Rittal is the largest member company in the owner-operated Friedhelm Loh Group. The Friedhelm Loh Group operates worldwide with 18 production sites and 80 international subsidiaries. The entire group employs 11,500 people and generated revenues of around €2.5 billion in 2017. In 2018, the family-run business was named one of Germany’s leading employers by the Top Employers Institute, for the tenth year running. Within the scope of a Germany-wide survey, Focus Money magazine identified the Friedhelm Loh Group as one of the nation’s best providers of vocational training for the third time in 2018.

For more information, visit www.rittal.com and www.friedhelm-loh-group.com.

Rittal GmbH & Co. KG

Auf dem Stützelberg

35745 Herborn

Telefon: +49 (2772) 505-0

Telefax: +49 (2772) 505-2319

http://www.rittal.de

Presse- und Öffentlichkeitsarbeit / Presseansprechpartner

Telefon: +49 (2772) 505-2693

E-Mail: koch.hr@rittal.de

Leiterin Unternehmenskommunikation

Telefon: +49 (2772) 5052527

E-Mail: wiechens-schwake.r@rittal.de

Telefon: +49 (2772) 505-1328

E-Mail: abels.c@rittal.de