One example is the new menu item "New". Clicking the menu item "New" closes the current calculation and opens the calculation module with the internal TBK default setting for all values.

The calculation modules "Cylindrical single gear“, "Three- and four-gear train systems“ as well as "Gear rack" have been enhanced. The modules now include DIN 58405 for fine mechanics, ISO 1328 and ANSI/AGMA 2015 in addition to DIN 3961 for gear tolerances/gear qualities.

The SKF bearing selection in the bearing module has also been updated. The new filtering function enables user to search for "Popular items" easier and faster. Popular items have a high level of availability and generally provide a cost-effective solution. The new release also adds SKF Explorer bearings. The Explorer bearings are marked which makes it much easier for customers to select the right bearing. There is also a new direct link to open the SKF online catalogue.

For the DXF output of the 2D gear tooth form, a new function for setting the minimum point distance has been added to all gear modules. This makes it easy to set the accuracy and point density for the output of the tooth form in order to use it for wire and laser cutting.

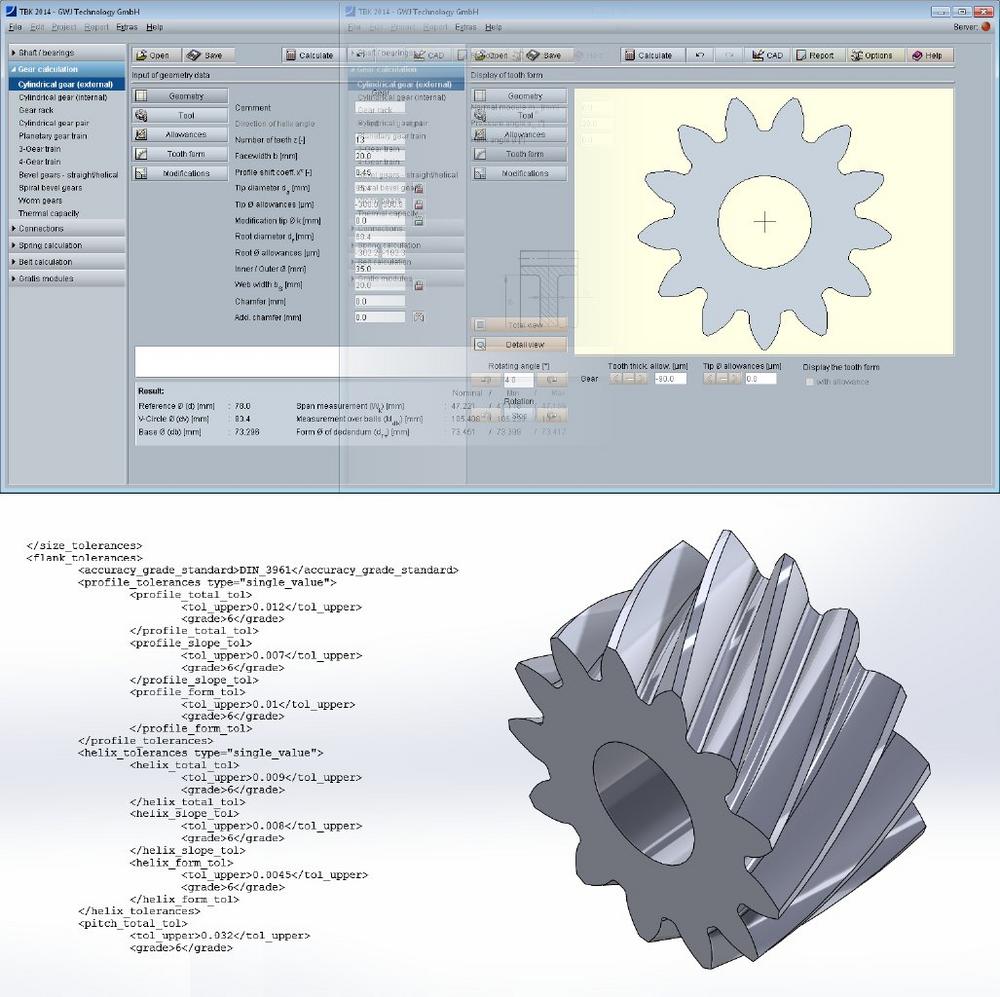

Data reuse seems like a topic that’s been covered for a long time, especially in the industry 4.0 era. With the integration of the standardised GDE format into the modules for gears and involute splines, TBK takes a step closer to a seamless data workflow.

GDE stands for Gear Data Exchange. This format, which is defined in VDI/VDE guideline 2610, is already supported by many measuring machine manufacturers. With the GDE format, geometries of cylindrical gears and involute splines can be loaded directly from the software into the measuring machine. It only takes a few clicks to create a measuring program. This avoids transmission errors and allows to work with standard measuring instructions. By means of the GDE format, data transfer to cutting machines could be also an option.

Visit www.gwj.de for more information or contact GWJ at +49 (0) 531 1293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology, a leading engineering company with its headquarter in Braunschweig, Germany, stands for high quality products and innovative software development. With keen insight, high energy and an enthusiastic team of engineers, we put our utmost efforts, skills, knowledge and passion into our work to achieve top quality products. Our portfolio includes the development of standard calculation software for machine elements, such as shafts, rolling bearings, cylindrical gears, bevel gears, etc. To increase the efficiency in the design process and to combine calculation and CAD, we provide CAD plugins for various 3D CAD systems. Our software solutions are designed with a sleek user interface, making it easier than ever to design or re-calculate machine elements. Additionally, we have geared our company to offer a special software application for the determination of real 3D tooth form geometries of complex gears. The tooth form is the basis for a 3D model to manufacture gears in conjunction with multi-axis machining centers. The software opens completely new possibilities for engineering.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

Geschäftsführer

Telefon: +49 (531) 1293990

Fax: +49 (531) 12939929

E-Mail: g.weser@gwj.de