One of the main challenges in the aerospace industry is to accurately predict acoustic and vibration responses under rocket launch conditions, as the intense acoustic field experienced during the early launch phase, including liftoff, can cause severe structural damage. Specifically, the integrity of both the spacecraft and protective fairing, along with sensitive ground-based equipment, can be impaired at launch. Most approaches to evaluate launch acoustic conditions use older calculation or empirical methods and rely heavily on trial-and-error testing information from legacy designs. These provide little opportunity for design optimization and such methodology can lead to inaccurate results, conservative assumptions, excess weight, and are likely to neglect frequency-dependent characteristics. In this context, independent engineering firm Space Structures GmbH sought to employ an advanced simulation methodology that would eliminate such limitations.

Specialized in the development of metal and composite structures for space applications, Space Structures was commissioned by the European Space Agency to develop a multi-functional panel for large satellites. Building on their core competences in the development of carbon-fiber composite structures for large spacecraft and years of experience in designing the right equipment for launch environments, Space Structures envisioned a new, cutting-edge methodology that would reduce uncertainties related to the ability of the structures to withstand the launch acoustic environment, and would enable them to address the topic early in their design process. As they laid out this ambitious project, Space Structures decided to extend their simulation capabilities to include the prediction of structural stress and strength responses during acoustic excitation.

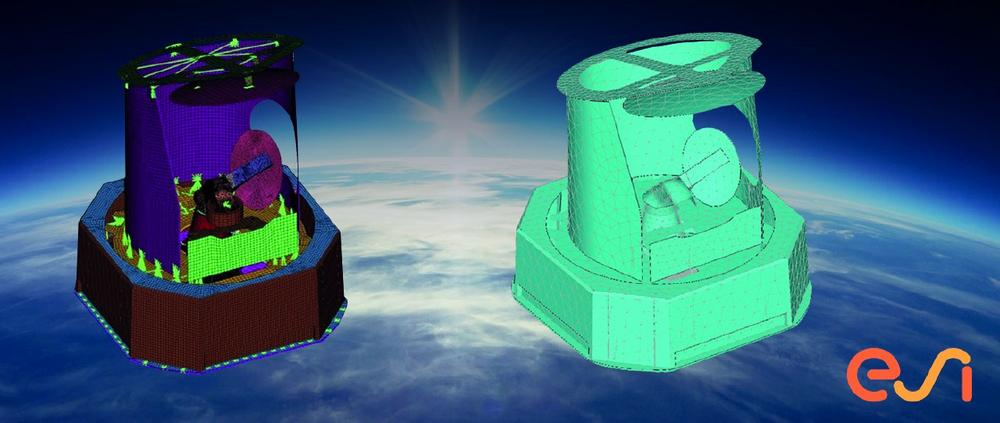

With help from ESI teams, Space Structures created a Boundary Element Model (BEM) with more than 250,000 nodes, a landmark achievement unthinkable in the industry just 10 short years ago. Florian Ruess, Managing Director of Space Structures GmbH, comments: "ESI VA One is an outstanding software product. However, the real success is provided in the proactive, flexible, timely and high-quality support of the ESI team from our first contact with the sales team to our contact with technical support."

Today, Space Structures has expanded their business thanks to the simulation tool and now have a customer service department that routinely conducts analytical verification and design optimization of spacecraft structures, including vibro-acoustic simulation. With the assistance of ESI’s technical service, Space Structures learned to benefit from the comprehensive functionality of VA One across the full-frequency range. The company realized a high return on investment and saw raised levels of customer satisfaction. In the future, Space Structures intends to continue their use of VA One to improve structural design for all acoustic noise environments For more information about ESI’s solution for vibro-acoustics simulation, please visit:

ESI Group is a leading innovator in Virtual Prototyping software and services. Specialist in material physics, ESI has developed a unique proficiency in helping industrial manufacturers replace physical prototypes by virtual prototypes, allowing them to virtually manufacture, assemble, test and pre-certify their future products. Coupled with the latest technologies, Virtual Prototyping is now anchored in the wider concept of the Product Performance Lifecycle™, which addresses the operational performance of a product during its entire lifecycle, from launch to disposal. The creation of a Hybrid Twin™, leveraging simulation, physics and data analytics, enables manufacturers to deliver smarter and connected products, to predict product performance and to anticipate maintenance needs. ESI is a French company listed in compartment B of NYSE Euronext Paris. Present in more than 40 countries, and addressing every major industrial sector, ESI Group employs about 1200 high-level specialists around the world and reported annual sales of €135 million in 2017. For more information, please visit www.esi-group.com.

Engineering System International GmbH

Siemensstr. 12

70565 Stuttgart

Telefon: +49 (6102) 2067-0

Telefax: +49 (6102) 2067-111

http://www.esi-group.com

Media Relations

Telefon: +33 (1) 417358-46

E-Mail: Celine.Gallerne@esi-group.com

Marketing Assistant

Telefon: +49 (6102) 2067-179

Fax: +49 (6102) 2067-111

E-Mail: Vanessa.Seib@esi-group.com

![]()