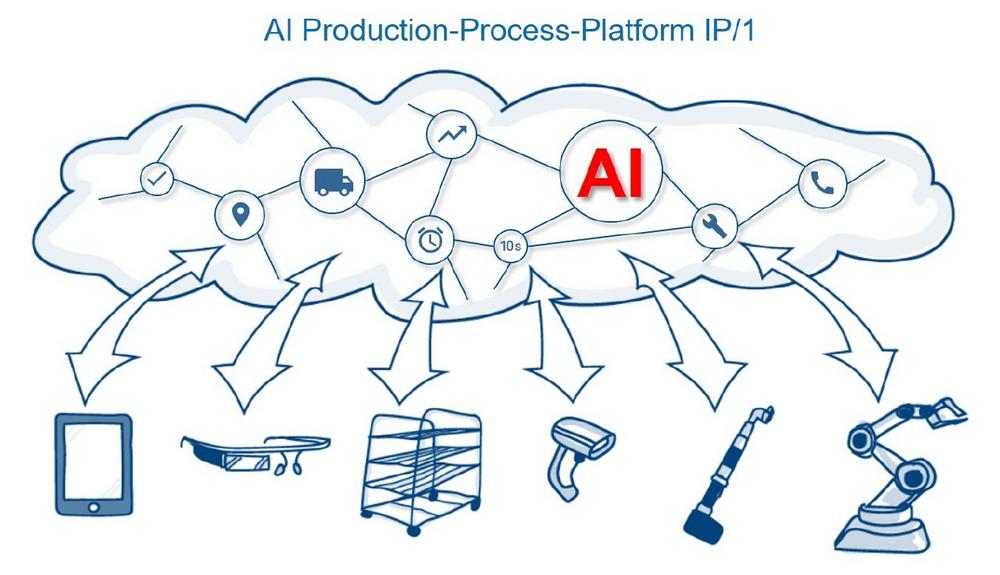

nextLAP Inc. will present its SmartRack and pickEXPLORER solutions at the Automotive Logistics Global Conference. Both solutions are integrated into the in-house developed cloud-based AI Production-Process-Platform IP/1. The platform collects process parameters from production and logistics – for example, when and where a part was installed, installation rates or the current location of a truck that is delivering parts to the factory. With the help of real-time data and existing empirical values, which are pooled on the platform and put into context, nextLAP develops algorithms that can make autonomous decisions for improvement and feed them back into the process. In line with nextLAP’s predictive process control philosophy, the Production-Process-Platform instantly recognises anomalies, autonomously identifies potential problem-solving scenarios and takes countermeasures before the fault can actually occur.

The platform uses relevant data sources to create a digital real-time overview of the production and logistics processes and thus serves as the basis for the planning, development, management and monitoring of processes. It integrates both IIoT hardware developed by nextLAP itself and technologies from third parties such as scanners or data glasses.

Intralogistic process savings and improvements in quality

Both the SmartRack and pickEXPLORER nextLAP solutions for optimising material flows build on the IP/1 AI platform. SmartRack is used for digitising and automating all types of order-picking processes and includes IIoT buttons with LED display, controller and a screen or tablet. The storage racks and areas are equipped with these IIoT components and connected to the nextLAP IP/1 platform.

The data collected in SmartRack from order-picking processes (e.g. part number, shaft, number of picks) establishes the core for pickEXPLORER, a solution for layout-based planning and the analysis of intralogistic areas. pickEXPLORER optimises routes, throughput times and ergonomics, resulting in process cost savings of up to 50 per cent.

“With their AI technologies, our solutions contribute to the implementation of self-optimised factories. They are employed by many companies, including leading international automotive OEMS. Using SmartRack, a leading German automotive manufacturer was able to significantly improve the quality of its order-picking process, achieving almost zero-defect order picking. This resulted in order picking cost savings of 30 per cent”, explains André Ziemke, Managing Director of nextLAP Inc. He adds: “Our attendance at the Automotive Logistics Global Conference 2018 in Detroit underlines our international outlook – it shows that factories have similar requirements, whether for German manufacturers or across the pond”.

For more information, see https://automotivelogistics.media/events/global/2018-2/home

nextLAP Inc. was founded in late 2016 by former Audi managers and is based in Mountain View, California. Based on many years of profound industry experience in Production, Logistics & IT, the company developed the AI Production-Process-Platform IP/1. It brings together Engineering & Execution of any Manufacturing & Logistics processes, pushing towards the self-optimizing Factory of the Future that autonomously takes decisions based on AI. nextLAP’s SmartRack product family enables their customers to digitize Production and Logistics processes themselves. The big data obtained from the digitized processes is played back to the AI Production-Process-Platform IP/1. Using algorithms and artificial intelligence, improvement measures and alternative actions for decision making are generated real-time. All nextLAP’s solutions are leased "as a service" on a monthly basis with no fixed term; usage, maintenance and support are included. The company’s customers include leading premium automotive manufacturers in the USA and Germany. (www.nextlap.io)

nextLAP GmbH

Hofmannstraße 61

81379 München

Telefon: +49 (89) 999533725

http://www.nextlap.de

PR-Redaktion

Telefon: +49 (211) 9717977-0

E-Mail: cp@punctum-pr.de

President

Telefon: +49 (89) 999533725

E-Mail: aziemke@nextlap.io

punctum pr-agentur GmbH

Telefon: +49 (211) 9717977-0

E-Mail: pr@punctum-pr.de