- Electrification of components for actuators: high performance operation

- Electric screw compressor: quiet air supply

- In Motion Charging: high-performance flexible charging system

“We target minimal emissions”: under this banner, Knorr-Bremse, the global market leader for braking systems and a leading supplier of other rail and commercial vehicle systems, offers a range of solutions aimed at continuously improving the environmental footprint of commercial vehicles. Such solutions will help towns and cities looking to meet their emissions targets, and fleet operators and vehicle manufacturers facing ever more stringent emissions standards.

As Dr. Peter Laier, Member of the Executive Board of Knorr-Bremse and responsible for the Commercial Vehicle Systems division, explains, “The preparations for more restrictive regulations on emissions and the accompanying trend toward zero-emission powertrains mean that component electrification is taking on new importance. Electrification allows components to be seamlessly integrated into the overall vehicle system and paves the way for high performance actuators. Our portfolio extends from high-precision, fast-acting electric actuators and intelligent controllers to high-performance electrical systems for vehicle propulsion and on-board power supply. At the same time, all-mechanical solutions too are contributing to improved environmental performance and efficiency.”

Thorsten Seehars, Member of the Management Board of Knorr-Bremse Commercial Vehicle Systems, adds: “There are a range of levers that can be used to reduce the emissions either of individual vehicles or of entire fleets. For example, even a small modification to an actuator can have a big impact on emissions. And of course, it should not be assumed that electrically actuated components are always more efficient than intelligently designed mechanical solutions. So, the fact that Knorr-Bremse possesses the same expertise in extremely robust and efficient mechanical systems as it does in the field of electric actuators and flexible charging concepts for electric vehicles is a definite advantage.”

CCA plus mechanical clutch actuator brings efficiency gains

The Concentric Clutch Actuator plus – or CCAplus for short – features a new all-mechanical design which minimizes dead volume. Dead volume is a standard feature of modern clutch actuators, ensuring that the actuator not only allows for actual clutch travel but can also compensate for wear. In terms of the pneumatic system, this means that every time the clutch is operated, a larger cylinder volume is pressurized than is actually needed to actuate the clutch.

On average, the dead volume of a clutch system measures approximately 450 cc at the beginning of the service life of the clutch. This compares with a stroke volume of only around 360 cc. The greatly reduced dead volume of the new CCAplus improves control accuracy, which results in faster clutch operation. No adjustment is required thanks to an allmechanical self-adjustment system, which ensures consistent control characteristics throughout the service life. CCAplus leads to an overall reduction in compressed air consumption, which is also reflected in reduced fuel consumption.

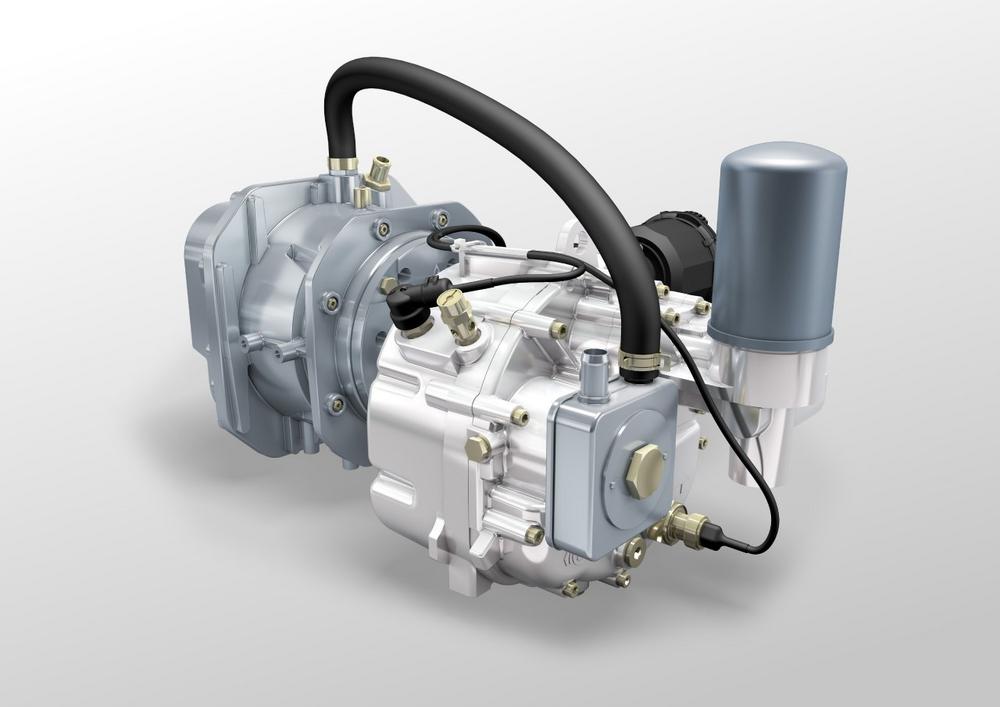

Electric screw compressor – quiet air supply

At the IAA Commercial Vehicles show in Hanover, Knorr-Bremse is presenting a new electric compressor with more compact dimensions – weight has been reduced by 25% and space requirements by 30% – and customizable control. The electric compressor is inherently much less vibration-prone than the piston compressors normally used on diesel vehicles. The fact that it reduces unwanted noise emissions to a minimum, emitting little more than a slight whirring noise when running, makes it a natural choice for electric and hybrid vehicles. Low noise is an important requirement since all-electric vehicles too feature a large number of pneumatically actuated components, and therefore require an efficient and highly reliable compressed air supply.

In addition to the brakes, such components also include door opening and closing mechanisms (in the case of buses) and chassis air suspension systems. Smarter compressor control allows the battery’s energy reserves to be optimally managed, all the way to conversion of braking energy into electricity for driving the compressor. The design of the compressor has been optimized to ensure minimized downtimes over the entire vehicle service life.

Electrically actuated exhaust valves – seamless adjustment

The electrically actuated exhaust valve systems from GT Emissions Systems, a Knorr- Bremse Group company, provide high-precision control of the engine air and temperature management system. Unlike their mechanical counterparts, they allow air flow to be seamlessly adjusted – for optimal adaptation to current engine operating conditions. These components are an important support for manufacturers of diesel engines in implementing their emissions strategies and complying with current and future international emissions standards such as Euro VI, Tier 4 or the Japanese standard pPNLT.

In Motion Charging – high-performance charging system maximizes flexibility

The most important constraint for large electric vehicle fleets is battery capacity. From overnight charging, which allows the vehicle to cover its full daily mileage on a single charge, to flash charging at bus stops or use of terminus charging stations, a range of stationary charging systems are currently in use. These systems only charge the vehicle when it is not in motion. The In Motion Charging (IMC®) concept adopts a different approach. Here the vehicle is charged from the overhead power lines while on the move, wherever such lines are available. Alternatively, on sections of the route where no overhead lines are available it operates like a battery bus. The advantage is that a smaller battery can be used than if the vehicle had to rely solely on overnight charging, while charging-related downtimes become a thing of the past. The fact that charging can be distributed in a balanced way across the day reduces peak loads which, just like with rail vehicles, reduces power supply costs for large fleets. To exploit synergies, it is possible to use the same substations as any pre-existing metro, mass transit or light rail systems. Similarly, it is also possible to use ready-trained personnel specialized in the relevant infrastructure and vehicle technology.

At this year’s IAA, Kiepe Electric will be presenting the IMC500 concept for in-motion charging of battery buses at a rate of up to 500 kW. Wherever overhead lines are available, the IMC500 concept allows all sub-systems to be charged at the same time, namely the two 160 kW motors (= 320 kW), the HVAC system and the battery, which can be charged at a rate of 200 to 300 kW. The higher the charge rate, the less time the vehicle needs to spend under overhead lines to keep the batteries regularly topped up, which reduces the amount of overhead line infrastructure required. Since only a minimal overhead line system (approx. 20% of the total network) is needed, the IMC500 concept results in minimized infrastructure costs.

The new concept allows e-buses and charging infrastructure to be used very efficiently, and results in reduced operating costs for the system as a whole. The increased time available for charging, and higher charging rates, make it possible to provide robust and reliable ebus services.

Knorr-Bremse: Shaping tomorrow’s transportation. Together.

Along with traffic safety, the megatrends that will shape the mobility sector in the next few years will be connectivity, emissions reduction, electric mobility and automated driving. Against this backdrop, Knorr-Bremse will be the systems partner for its customers going forward and will be driving forward developments in all four core areas in close collaboration with its customers. Knorr-Bremse will be presenting its portfolio of products and services at the commercial vehicle industry’s key trade fairs in 2018 – IAA and Automechanika. Activities and innovations on show will include pioneering traffic safety technologies and automated transportation solutions for highway and city applications, set out under the motto Shaping tomorrow’s transportation. Together.

Come and see Knorr-Bremse at the IAA Commercial Vehicles show in Hanover from September 20-27, on booth A30 in hall 17 and in outdoor area D107. At the Automechanika fair in Frankfurt am Main from September 11-15, Knorr-Bremse will be on booth 91 and booth 98 in hall 3.0.

Knorr-Bremse is the global market leader for braking systems and a leading supplier of other safetycritical rail and commercial vehicle systems. Knorr-Bremse’s products make a decisive contribution to greater safety and energy efficiency on rail tracks and roads around the world. For more than 113 years the company has been the industry innovator, driving innovation in mobility and transportation technologies with an edge in connected system solutions. Knorr-Bremse is one of Germany’s most successful industrial companies and profits from the key global megatrends: urbanization, ecoefficiency, digitization and automated driving.

About 28,000 employees at over 100 sites in more than 30 countries use their competence and motivation to satisfy customers worldwide with products and services. Localization is a central focus of Knorr-Bremse’s strategy. Knorr-Bremse delivers braking, entrance, control and auxiliary power supply systems, HVAC and driver assistance systems for rail vehicles, as well as braking, steering, powertrain and transmission control solutions, and driver assistance systems for commercial vehicles.

In 2017, Knorr-Bremse’s two divisions together generated revenues of EUR 6.2 billion (IFRS). A comprehensive aftermarket & services business with high entry barriers gives these revenues increasingly cyclically independent stability. The company benefits from strong, entrepreneurial and experienced management. Technical excellence, reliability, passion and responsibility are deeply embedded in its corporate culture.

Knorr-Bremse AG

Moosacher Straße 80

80809 München

Telefon: +49 (89) 3547-0

Telefax: +49 (89) 3547-2767

http://www.knorr-bremse.de

Corporate Communications

Telefon: +49 (89) 35471498

Fax: +49 (89) 444454-193

E-Mail: eva.doppler@knorr-bremse.com

Head of Corporate Communications

Telefon: +49 (89) 3547-1402

E-Mail: alexandra.bufe@knorr-bremse.com