With Poraver® you can produce purely mineral construction materials that meet all requirements to building physics and building biology with excellent values. Especially thermal insulation is very important. By adding Poraver®, a suitable monolithic building material can be produced depending on the application. Time-consuming and costly external thermal insulation composite systems (ETICS or EIFS) can become superfluous.

Applications for thermal insulating lightweight concrete with Poraver®

Walls & thermal separations

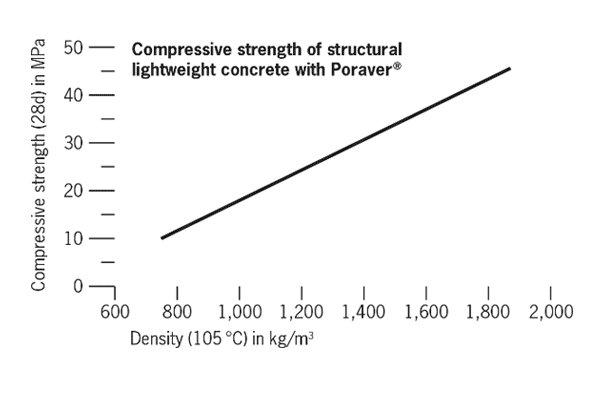

Compared to other lightweight aggregates, Poraver® expanded glass has a very positive ratio of compressive strength to bulk density. This enables single- and multi-layer structures with very good thermal insulation properties and at the same time good compressive strength. The production of load-bearing and insulating roller shutter boxes is feasible due to the excellent properties of Poraver® lightweight concrete, as well as the thermal separation of windows, door frames and other components.

Insulation of flat roofs & ceilings

In modern residential buildings with a flat roof, bound Poraver® can be installed as a load-bearing roof insulation. For suspended ceilings, bound Poraver® serves as a levelling layer to cover pipelines and as an insulating base layer for underfloor heating systems. The use of Poraver® contributes to meet the requirements of modern passive houses and ecological standards in construction.

Production

By using different Poraver® grain sizes, thermal insulation concretes with densities from 270 kg/m³ to 800 kg/m³ can be produced. Based on the available grain fractions, an optimized grading curve can be created. Depending on the requirements, thermal conductivities of ≥ 0.07 W/(m∙K) or 28d compressive strengths of up to 13 N/mm² can be achieved for thermal insulating lightweight concretes. In general, Poraver® can be used to produce porous and dense lightweight concretes of all density classes.

Guide formulations

On request, we offer various guide formulations for lightweight concretes with Poraver® of different density classes. In addition, if you need support by our application engineering department, don’t hesitate to contact us! Please use our contact form!

Poraver® advantages at a glance

- Weight reduction

- Excellent thermal insulating properties

- Non-combustible (Building material class DIN 4102-A1)

- Consistent lightweight aggregate quality due to industrial production

- Secured availability

- Protects natural resources (made from post-consumer recycled glass)

Examples of applications for Poraver® LWC

- Monolithic or multi-layered wall construction

- Thermal separations on floor slabs

- Insulation of roller shutter boxes

- Thermal separation bricks

- Mineral insulation for flat roofs

- Bound levelling fill for covering pipelines

- Load-bearing insulating layer under underfloor heating systems

PORAVER GmbH

Mozartweg 1

96132 Schlüsselfeld

Telefon: +49 (9552) 92977-0

Telefax: +49 (9552) 92977-26

https://poraver.com

Marketing Kommunikation

Telefon: +49 (9552) 92977-51

E-Mail: nestmann@poraver.de

![]()