Operating several coupled systems safely

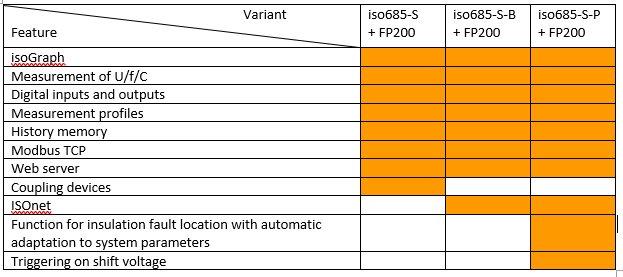

As several insulation monitoring devices can interfere with each other due to the measuring procedure, in accordance with IEC 61557-8 only one insulation monitoring device is allowed to be present in an unearthed system (IT system). On board, the individual control panels of the generators are operated both separately and coupled to keep the operating hours to a minimum. If these systems are connected via the coupling switches, there will be several insulation monitoring devices in one IT system. The variants iso685-S-B/P + FP200 are suitable for this application. This allows several insulation monitoring devices to be used in a coupled system without being influenced by closed coupling switches.

The insulation monitoring devices can be deactivated directly via the feedback of the coupling switches or by interconnecting the devices. The ISOMETER®s measure one after another and only one is active at a time – Bender calls this function ISOnet.

Comfortable insulation monitoring and fault location

The larger the unearthed and on board usually coupled systems (IT systems) to be monitored, the more difficult it is to locate possible insulation faults. This challenge is met with the help of automatic insulation fault location systems, the function of which can be carried out during operation. Also, faults can be narrowed down which occur only sporadically because the faulty systems, such as pumps or winches, only run for a short time.

The results are increased system availability and minimised downtime periods. Additional electrical components are required for insulation fault location systems.

The iso685-S-P + FP200 variant without an integrated display in combination with an extra display for the assembly in control cabinet doors, can be used for systems with insulation fault location. An integrated locating current injector creates a limited locating current to earth when an insulation fault occurs. This locating current can be adjusted. With insulation fault locators of the ISOSCAN® series, the locating current can assign the fault to the exact distribution or even the exact load by means of measuring current transformers. The iso685-S-P + FP200 can communicate with the insulation fault locators EDS440 and EDS441 via an RS-485 sensor bus or via a backbone bus. All required settings for the EDS440 and EDS441 can be made via the remote FP200 display of the iso685-S-P. It is possible to program each channel separately or all channels at once.

New measuring methods allow locating high-impedance faults with high system leakage capacitances and low locating currents. The faulty channels are indicated on the remote FP200 display of the iso685-S-P and can be replaced by plain text messages. For example, in the event of an insulation fault on a motor the message "Insulation fault compressor 1" could be displayed. This allows the location of a fault without having to study the wiring diagram and therefore facilitates the insulation fault location. Of course, all the features of the iso685-X-B variant are included in the iso685-X-P.

In DC systems, the iso685-S-P + FP200 can be triggered and issue a prior warning if there is a DC offset voltage measured against earth. The corresponding response values for these prior warnings and the disconnection can be adjusted in 5-V steps.

See picture iso685-S series.

Bender GmbH & Co. KG

Londorfer Str. 65

35305 Grünberg

Telefon: +49 (6401) 807-0

Telefax: +49 (6401) 807-259

http://www.bender.de

Kommunikation

Telefon: +49 (6401) 807-519

E-Mail: daniela.theiss@bender.de

![]()