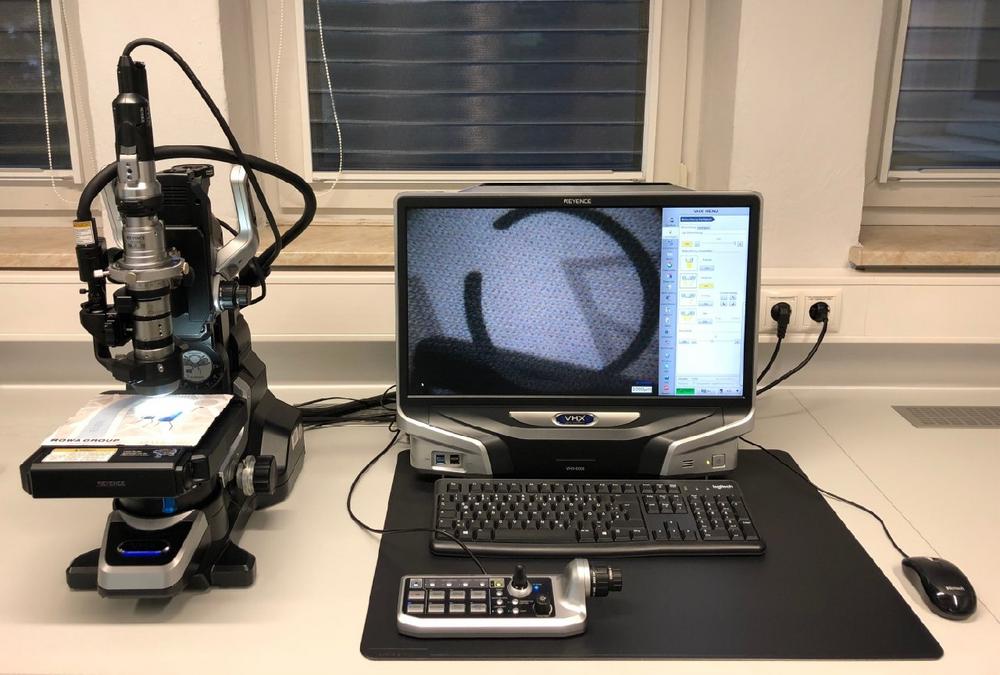

Depending on the specific problem and the necessary resolution, users can chose between two different lenses that cover the range from 20 to 200 and 500 to 5000 times magnification. Compared to classic light microscopy, digital microscopy gives users the chance to view, measure and save the images directly on a computer. Images with a very high depth-of-field at high magnifications can also be produced with digital microscopes. An additional effect during the generation of these images with large depth-of-field is the simultaneous production of 3D images of the object being observed, which can also be measured using the corresponding software.

In order to always be able to put the samples under investigation in the best light, coaxial illumination through the lens or lateral, adjustable-angle illumination are available to the user. These different kinds of lighting can also be combined with one another. Furthermore, a panorama image consisting of several individual images can be produced to show larger objects in a high resolution and magnification.

Polarization filters, HDR imaging and free-angle observation of three-dimensional objects round off the possibilities offered by the new digital microscope.

ROWA Lack GmbH gladly offers its customers to help them identifying coating problems, defects and failures in lacquer films.

About ROWA Lack:

The ROWA Lack GmbH was established in 1958 and is a partner in the ROWA GROUP of companies. The brand ROWA stands for technical competence, modern product design and customer oriented service the world over. Tailored customer solutions are part of the ROWA tradition and are a matter of course! The development of new products, the search for alternative raw materials and the constant and sustained optimization of our processes, coupled with modern technology, motivated employees and economical environment protection enjoy the highest priority in our company. In 2010 the ROWA GmbH has been renamed into the ROWA GROUP Holding GmbH and the departments Masterbatch and Lack were newly formed as ROWA Masterbatch GmbH und ROWA Lack GmbH specialist division: Special Lacquer Systems and Top Coats.

ROWA GROUP Holding GmbH

Siemensstraße 1-9

25421 Pinneberg

Telefon: +49 (4101) 70606

Telefax: +49 (4101) 706203

http://www.rowa-group.com

Telefon: +49 (4101) 706-189

E-Mail: d.stoltenberg@rowa-lack.de