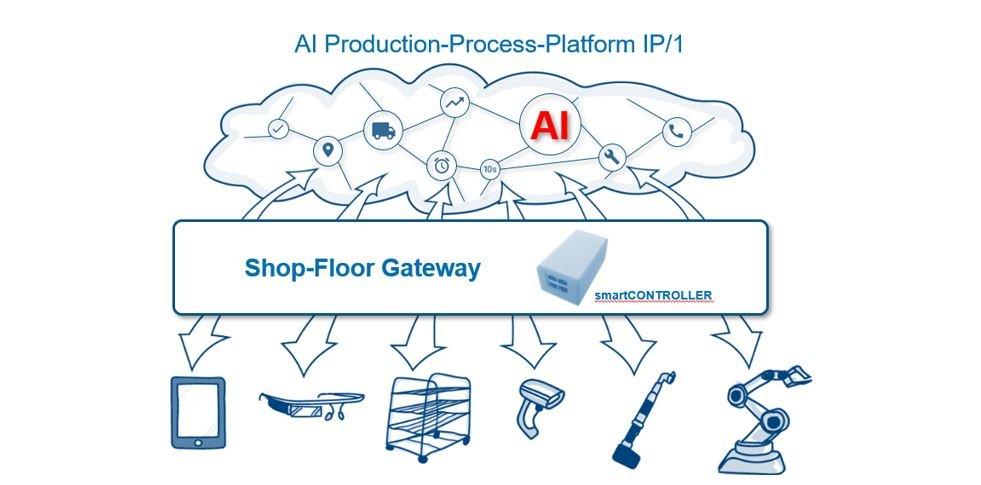

nextLAP is a provider of AI-based solutions for the digital management and automation of production and logistics processes. The proprietary cloud-based AI Production-Process-Platform IP/1 is a data hub with real-time evaluation. When fully integrated, it can be used to implement applications for AI-supported optimisation of material flows in factories, for example.

The IP/1 platform creates a digital real-time map of the production and logistics processes. Real-time data and existing empirical values are pooled on the platform and put into context. Using algorithms, the platform can make autonomous decisions for improvement and feed them back into the process. It instantly recognises anomalies, autonomously identifies potential problem-solving scenarios and takes countermeasures before a fault can actually occur.

smartCONTROLLER: automation made super easy

The IP/1 platform integrates both IIoT hardware developed in-house by nextLAP and technologies from third parties such as scanners or data glasses. The smartCONTROLLER shop-floor gateway enables a “connect whatever you like” approach. Using plug-and-play, it can be easily installed on existing hardware on the shop floor such as a shelf. Its extremely compact, robust housing (protection class IK06) makes the gateway ideal for industrial use. It is affordable, simple and flexible to use, making it a viable alternative to complex automation technology.

“The new-generation smartCONTROLLER is even more closely geared to the requirements of the shop floor and ensures that production-critical data is securely communicated. In addition to an RJ-45 network connection, the smartCONTROLLER can also be wirelessly connected to the production network. The solution can be updated over the air and has optimised interfaces such as an additional USB hub inside the housing, which allows a scanner to be connected, for example. The power supply, or more specifically, the ability to charge connected third-party devices, has also been integrated,” explains André Ziemke, Managing Director of nextLAP GmbH.

nextLAP GmbH

Hofmannstraße 61

81379 München

Telefon: +49 (89) 999533725

http://www.nextlap.de

PR-Redaktion

Telefon: +49 (211) 9717977-0

E-Mail: cp@punctum-pr.de

Managing Director

E-Mail: aziemke@nextlap.io

Managing Director

Telefon: +49 (211) 9717977-0

E-Mail: pr@punctum-pr.de