▪ Trade fair booths focused on megatrends of urbanization, digitization and eco-efficiency

▪ Maintenance contract signed with Siemens Mobility Services for Desiro, Velaro and locomotive fleets

▪ Memorandum of understanding signed with Siemens Mobility Services on integration of iCOM apps into Railigent®

▪ Cooperation with Perpetuum on vehicle component monitoring

▪ Presentation of iCOM Monitor condition monitoring project with Rheinbahn

▪ Project launched with Deutsche Bahn to pilot eco-friendly CO2 refrigerant for air-conditioning units

▪ During InnoTrans, Knorr-Bremse received first ever “authorization for placing in service” from the German Federal Railway Authority, in connection with a brake modernization project

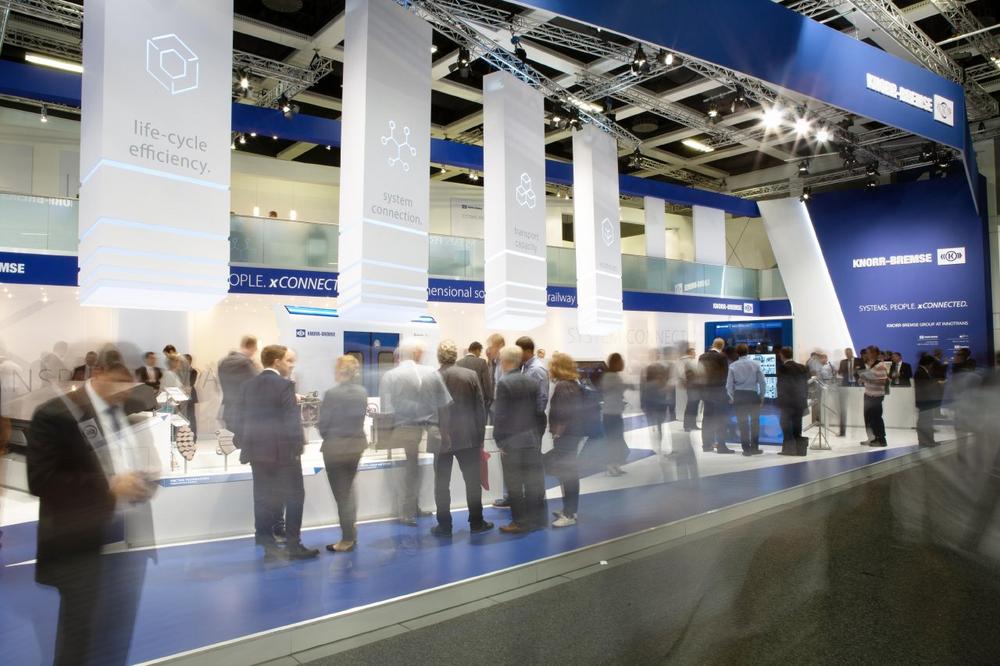

InnoTrans 2018 in Berlin was a great success and triggered several new business deals for Knorr-Bremse, the global market leader for braking systems and a leading supplier of other safety-critical rail and commercial vehicle systems.

“Our solutions for the market drivers of System connection, Life-cycle efficiency, Availability and Transport capacity, and Ecodesign were shown to add genuine value and met the requirements of vehicle manufacturers and rail operators around the world in full,” sums up Dr. Jürgen Wilder, Member of the Executive Board of Knorr-Bremse AG responsible for the Rail Vehicle Systems division.

Highlights of InnoTrans 2018:

Through its high level of systems expertise and broad product portfolio, Knorr-Bremse gives its customers the flexibility they need to develop advanced and connected rail vehicles. One highlight at InnoTrans 2018, for example, was the modular CCB-3 locomotive brake control system that was developed with all of the world’s most important rail transportation standards in mind. For vehicle manufacturers who aim to sell their locomotives in different markets, this leads to a reduction in cost and effort of redesigning their vehicles for specific markets.

Another focus of Knorr-Bremse Rail Vehicle Systems’ presence at the InnoTrans fair was on cutting the life-cycle costs of a vehicle or, in other words, boosting its life-cycle efficiency. With modular and high quality products and systems such as the EP2002 3.0 brake control system, optimized maintenance costs and obsolescence management solutions, Knorr-Bremse boosts vehicle availability and operational efficiency.

The third focal point for Knorr-Bremse Rail Vehicle Systems at the InnoTrans fair was on products and systems that help reduce CO2 and noise emissions. In this context, Knorr-Bremse Group company Kiepe Electric showcased its pioneering IMC (In Motion Charging) concept for trolley bus operation. On sections of the route without overhead lines, buses with IMC run like battery operated vehicles, with the batteries being charged on sections with overhead lines.

The presence of Knorr-Bremse Rail Vehicle Systems at this year’s InnoTrans was a complete success and greatly enhanced the company’s dialogue with its international customers. As a result, Knorr-Bremse is able to announce a number of new business deals and memoranda of understanding, as well as a groundbreaking pilot project, all concluded at the fair.

Agreements with Siemens

Knorr-Bremse RailServices has concluded a long-term maintenance agreement with Siemens Mobility, covering multiple countries. The aftermarket specialists will carry out the braking system maintenance of all the Desiro and Velaro fleets that Siemens is responsible for maintaining in the UK and Russia, as well as its current locomotive fleets in Europe.

A memorandum of understanding has also been signed governing the incorporation of apps from Knorr-Bremse’s iCOM digital platform for the railway industry into the Siemens Mobility Services application suite, Railigent. The combination of Knorr-Bremse’s comprehensive component know-how and Siemens’ top-class maintenance and AI expertise can help customers to increase the availability of their fleets.

Better insight into the condition of vehicle fleets

A memorandum of understanding has also been signed with Perpetuum regarding the iCOM platform and its iCOM Monitor app. RailServices hopes to combine Perpetuum’s system for recording and monitoring vibrations of wheels, gearboxes, motors and wheel bearings with iCOM Monitor. This systems connection initiative will provide an enhanced insight into vehicle condition, enabling longer maintenance cycles and improved availability and thus reducing vehicle life-cycle costs and increasing transportation capacities. Knorr-Bremse also invited Düsseldorf-based operator Rheinbahn to present its implementation of the app in light rail vehicles. Online transmission of condition data from in-service LRVs has significantly improved the organization of workshop operations, reduced vehicle downtime and cut operating costs.

Pilot project for eco-friendly CO2 refrigerant

Kiepe Electric has signed an agreement with Deutsche Bahn to pilot an innovative airconditioning unit. Instead of a refrigerant based on environmentally harmful CFCs, its ecodesign employs natural and significantly more eco-friendly CO2. The difference is striking: the Global Warming Potential (GWP) of CFCs is between one and two thousand times that of CO2 (GWP 1).

The unit is based on a system already being used on a VT 642 diesel-electric vehicle belonging to Chemnitzer Erzgebirgsbahn. The new pilot agreement relates to two adapted systems for DB Regio double-decker passenger cars. “The partnership will benefit the Knorr-Bremse HVAC group by feeding real field data back into the development process. This data can then be used to further optimize the technology and demonstrate its suitability for volume production,” explains Peter Pichler, Managing Director of Kiepe Electric’s Vienna facility. “Our partner in this pilot project will benefit from being able to test the reliability of this new, ecofriendly technology in an operational environment.”

Federal Railway Authority (EBA) authorizes RailServices modernization solution

During InnoTrans, Knorr-Bremse also received news of a significant breakthrough with the Federal Railway Authority (EBA). On September 20, the EBA issued Knorr-Bremse Rail Vehicle Systems with its first ever “authorization for placing in service” (Inbetriebnahmegenehmigung – IBG). The authorization relates to a modernization project involving the new ESRA 3.0 brake control system. Knorr-Bremse RailServices fitted the new system in an existing Desiro Classic VT642 vehicle, helping to extend its service life and thus reduce its life-cycle costs. As well as carrying out the actual modernization of the braking system, for the first time ever the package also involved RailServices assuming full responsibility for the required additional vehicle approval procedure. “Obtaining the IBG means that Knorr-Bremse can now offer the complete package, including vehicle approval, to other Desiro Classic VT642 operators,” explains Mark Cleobury, Member of the Management Board at Knorr-Bremse Rail Vehicle Systems.

Knorr-Bremse is the global market leader for braking systems and a leading supplier of other safety-critical rail and commercial vehicle subsystems. Knorr-Bremse’s products make a decisive contribution to greater safety and energy efficiency on rail tracks and roads around the world. For more than 110 years the company has been the industry innovator, driving innovation in mobility and transportation technologies with an edge in connected system solutions. Knorr-Bremse is one of Germany’s most successful industrial companies and profits from the key global megatrends: urbanization, eco-efficiency, digitization and automated driving.

Approximately 29,000 employees (per June 30, 2018) at over 100 sites in more than 30 countries use their competence and motivation to satisfy customers worldwide with products and services. Localization is a central focus of Knorr-Bremse’s strategy. Knorr-Bremse delivers braking, entrance, control and auxiliary power supply systems, HVAC and driver assistance systems for rail vehicles, as well as braking, steering, powertrain and transmission control solutions, and driver assistance systems for commercial vehicles.

In 2017, Knorr-Bremse’s two divisions together generated revenues of EUR 6.2 billion (IFRS). A comprehensive aftermarket & services business with high entry barriers gives these revenues increasingly cyclically independent stability. The company benefits from strong, entrepreneurial and experienced management. Technical excellence, reliability, passion and responsibility are deeply embedded in its corporate culture.

Knorr-Bremse AG

Moosacher Straße 80

80809 München

Telefon: +49 (89) 3547-0

Telefax: +49 (89) 3547-2767

http://www.knorr-bremse.de

Corporate Communications

Telefon: +49 (89) 35471498

Fax: +49 (89) 444454-193

E-Mail: eva.doppler@knorr-bremse.com

Head of Corporate Communications

Telefon: +49 (89) 3547-1402

E-Mail: alexandra.bufe@knorr-bremse.com