For years, continuous miniaturization in the electronics and semiconductor industry has naturally forced even the device connectors to become ever tinier. This means probe cards for testing electronics must themselves be made smaller, too. A key component of probe cards are their guide plates. They contain a mechanically stable substrate with thousands of micro-bore-holes through which the probe card’s contact pins must be safely and precisely guided to facilitate subsequent reliable contact with the semiconductor device’s connectors. Substrates are made of ceramics. And it is exactly this material that is so challenging to process.

Greatest Flexibility Combined with Intuitive Operation

Posalux’ laser processing machine specifically addresses these requirements. The integrated sub-system by SCANLAB, coupled with an ultra-short-pulse (USP) laser, enables processing of highly diverse materials such as metals, polymers and ceramics, without affecting them thermally. The scan solution provides five axes for defined laser beam guidance in the machine’s x,y,z coordinate axes and a simultaneous superimposed, adjustable angle of incidence (positive or negative). This makes it ideal for fabricating micro-bore-holes with high aspect ratios and freely definable geometries. And the intuitive user interface lets machine operators easily load a bore image, assign process parameters and scan the workpiece surface.

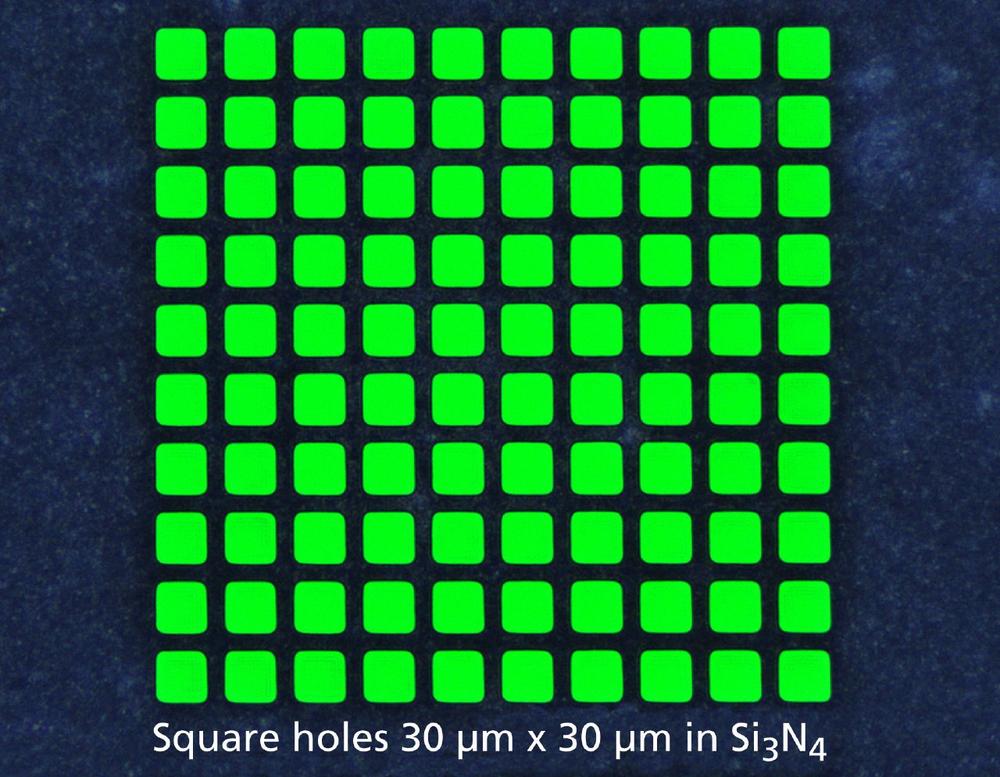

Industry insiders are well aware of the imperative to create ever-smaller bore geometries. This makes it all the more impressive that Posalux’s precSYS infrared machine already fulfills application specifications previously thought only possible at green wavelengths. Here, customers’ usage demonstrates that even bore holes specified for 30 µm x 30 µm edge lengths, 300 µm material thickness and 10 µm separation are consistently achievable. In that application case, 46,000 bore holes were examined for positioning accuracy of ±2 µm, and corner radii smaller than 5 µm were reliably achieved. Thus, the user has available a robustly designed machine for processing any desired geometries in the µm range, as well as their exact localization to ±2 µm, across a maximum working area of 300 mm x 300 mm.

“We’re pleased that our micromachining sub-system performs so well in applications. And we’ve received consistently positive feedback, not just from Posalux, but also from other integrators and users in additional industries. After these superb results, we increasingly look forward to the results of a precSYS ‘green variant’.” comments SCANLAB’s CEO Georg Hofner on the developments.

The precSYS sub-system is currently produced exclusively for infrared lasers with a 1030 nm wavelength. A new variant is being developed for green lasers with a 515 nm wavelength, to thereby enable even finer structures and corner radii. Availability of initial prototypes is expected in summer 2019.

With over 30,000 systems produced annually, SCANLAB GmbH is the world-leading and independent OEM manufacturer of scan solutions for deflecting and positioning laser beams in three dimensions. Its exceptionally fast and precise high-performance galvanometer scanners, scan heads and scan systems find application in industrial materials processing and the electronics, food and beverage industries, as well as biotech and medical technology.

For over 25 years, SCANLAB has secured its international technology leadership through pioneering developments in electronics, mechanics, optics and software, as well as the highest quality standards.

About POSALUX:

Since its founding in 1943, POSALUX SA has been a reference for implementing high-precision micromachining technologies in mass production. Headquartered in Biel, Switzerland, and with subsidiaries in Germany, Korea, Taiwan, and the USA, as well as a worldwide network of sales and service agents, Posalux is positioned to meet the highest customer requirements.

The company focuses on the enabling technologies of µ-machining & PCB (drilling, routing), SACE (spark assisted chemical engraving), EDM (electrical discharge machining) and femto lasers. This orientation provides the machine designs required for applications in the automotive, medical technology, electronics and watchmaking industries.

SCANLAB GmbH

Siemensstraße 2a

82178 Puchheim

Telefon: +49 (89) 800746-0

Telefax: +49 (89) 800746-199

http://www.scanlab.de/

Marketing & Kommunikation

Telefon: +49 (89) 800746-0

Fax: +49 (89) 800746-199

E-Mail: e.jubitz@scanlab.de