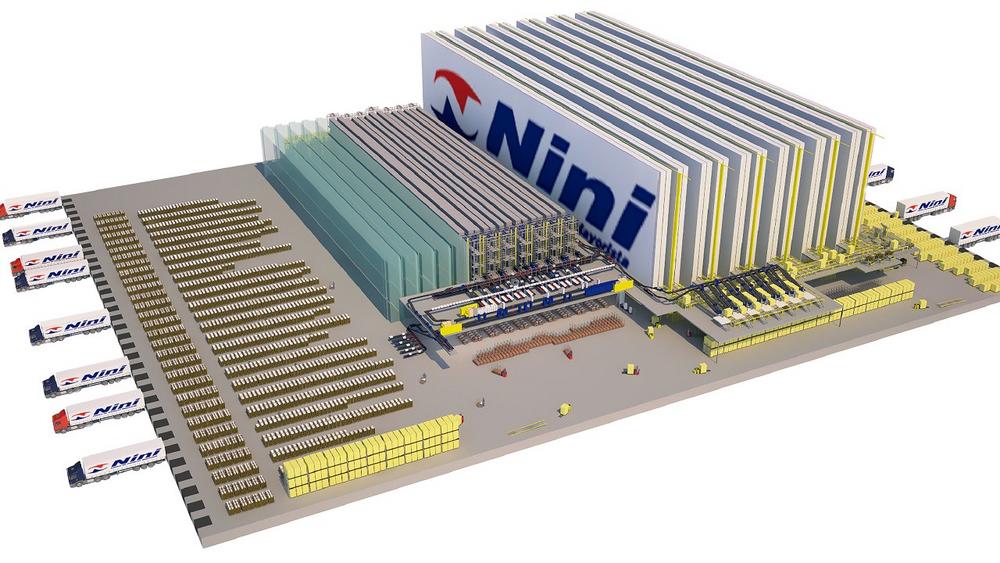

Fast store delivery, daily and seasonal volume fluctuations and continuously changing customer purchasing behavior are major challenges for wholesalers – hence, the intralogistics requirements also change. The new distribution center for Ricardo Nini S.A. in Moreno meets these requirements and will ensure the efficient supply of more than 3,000 stores in the Buenos Aires area as well as the directly connected 12,000 m² store with a wide range of dry food products and non-food items. The new logistics center covers an area of 32,000 m² and will accommodate 9,000 products. Every day, 1,100 pallets will be processed at goods-in, while 127,000 cases and 194,000 individual items will be picked.

Efficient processes with tailor-made automation

At goods-in, delivered pallets are checked and, if required, automatically put onto system pallets. The project’s core components are an automatic high-bay warehouse (HBW) with 37,000 pallet storage locations and a 7-aisle shuttle warehouse with 117,000 bin storage locations. In the HBW, 6 energy-efficient Exyz storage and retrieval machines (SRM) ensure double-deep storage and retrieval processes. In the shuttle warehouse, the items are first re-packed into bins at 12 ergonomic goods-to-person work stations and stored by the highly efficient single-level shuttle system Cuby.

Picking processes begin in an area with 990 pallet pick faces including automatic replenishment by the Exyz SRM, and then continue at 10 goods-to-person work stations for cases and 12 goods-to-person work stations for individual items. Additionally, a fleet of AGV will be in charge of automatic replenishment of entire pallets for the connected store. All areas in the new distribution center are connected by a pallet conveying system as well as a bin and carton conveying system. The scope of supply and services is rounded off by two bin stacker and de-stacker as well as the logistics software WAMAS, which controls all warehouse operations.

"We evaluated a large number of intralogistics options and solutions, and the solution proposed by SSI Schaefer has convinced us right from the beginning. We completely trust in the skills and experience of SSI Schaefer to plan, develop and implement holistic logistic systems including a tailor-made software as we requested," summarizes Carmelo Miguel Nini, owner of Ricardo Nini S.A.

The high-bay warehouse as well as the picking areas are planned to be in operation by the end of 2019.

The SSI Schaefer Group is the world’s leading provider of modular warehousing and logistics solutions. It employs approximately 10,500 people at its group headquarters in Neunkirchen (Germany), at more than ten domestic and international production sites, and at approximately 70 worldwide operative subsidiaries. Across six continents, SSI Schaefer develops and implements innovative industry-specific answers to its customers‘ unique challenges. As a result, it plays a key role in shaping the future of intralogistics.

SSI Schaefer designs, develops and manufactures systems for warehouses, industrial plants, workshops and offices. Its portfolio includes manual and automated solutions for warehousing, conveying, picking and sorting, plus technologies for waste management and recycling. In addition, SSI Schaefer is now a leading provider of modular, regularly updated software for in-house material flows. Its IT team, with a headcount in excess of 1,100, develops high-performance applications, and provides customers with in-depth advice on the intelligent combination of software with intralogistics equipment. SSI Schaefer’s broad IT offering, including its own WAMAS® and SAP products, delivers seamless support for all warehouse and material flow management processes. Solutions from SSI Schaefer improve the productivity and efficiency of customer organizations – not least through the highly precise monitoring, visualization and analysis of operational metrics for proactive intralogistics management.

SSI Schaefer offers highly sophisticated, turnkey systems. As an international player, it can deliver one-stop solutions to all four corners of the earth. Its comprehensive portfolio encompasses design, planning, consulting, and customer-specific aftersales services and maintenance.

SSI SCHÄFER

Fritz-Schäfer-Strasse 20

57290 Neunkirchen / Siegerland

Telefon: +49 (2735) 70-1

Telefax: +49 (2735) 70-396

http://www.ssi-schaefer.de

Marketing & Kommunikation

Telefon: +49 (2735) 70-252

Fax: +49 (2735) 70-382

E-Mail: melanie.kaempf@ssi-schaefer.de