Like the majority of Swedish retail companies, Stadium Sverige AB has experienced a strong development in the e-commerce sector. Customers expect a high level of service and fast delivery, which places new and increased demands on logistics processes as the volume grows.

"Due to the development of the digital trade in recent years, and especially in the past year, it has been absolutely necessary for us to find a more efficient logistics solution, where we switch from manual processes to automation," says Daniel Johansson, Logistics Manager, Stadium Sverige AB.

The automated system is designed as a flexible platform and can be used by several companies for handling their customer orders together with PostNord TPL AB in the future. The solution will be cost-effective regardless of the company size, the quantity of stored goods and the number of deliveries.

"The solution removes the threshold for smaller e-merchants to use an automated logistics system. They can benefit from it without the need to invest in their own system," says Magnus Lindskog, Production Manager, PostNord TPL AB.

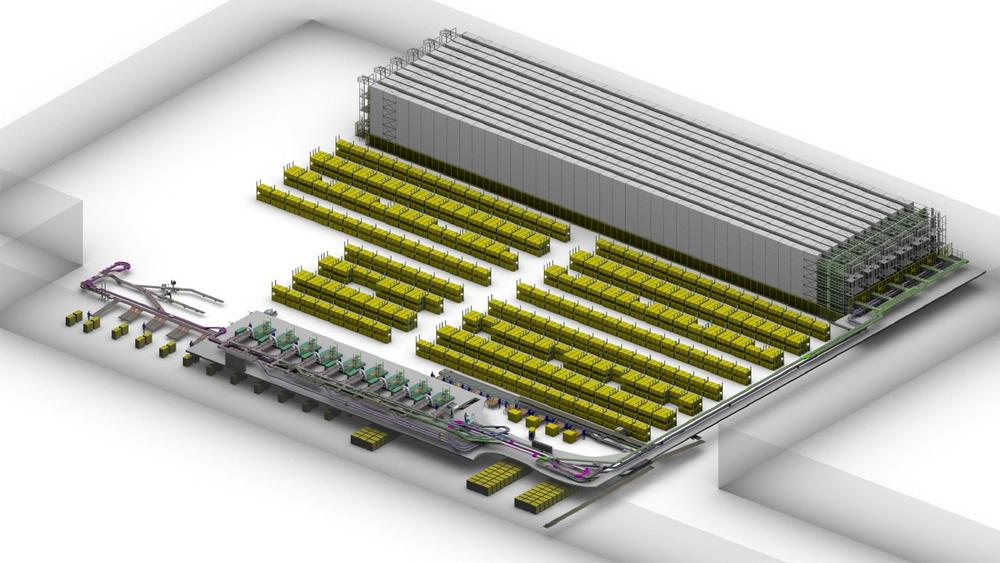

The automated, tailor-made solution is supplied by SSI Schaefer and will include a single-level shuttle system Cuby, packing stations, conveyors, shelves and a WMS system for controlling the entire warehouse. "The solution will consist of a 6-aisle shuttle warehouse with 74,000 storage locations for bins. Each aisle will be 100 meters long and 10 meters high," says Anders Bohlin, Sales Manager, SSI Schaefer Sweden.

The SSI Schaefer Group is the world’s leading provider of modular warehousing and logistics solutions. It employs approximately 10,500 people at its group headquarters in Neunkirchen (Germany), at more than ten domestic and international production sites, and at approximately 70 worldwide operative subsidiaries. Across six continents, SSI Schaefer develops and implements innovative industry-specific answers to its customers‘ unique challenges. As a result, it plays a key role in shaping the future of intralogistics.

SSI Schaefer designs, develops and manufactures systems for warehouses, industrial plants, workshops and offices. Its portfolio includes manual and automated solutions for warehousing, conveying, picking and sorting, plus technologies for waste management and recycling. In addition, SSI Schaefer is now a leading provider of modular, regularly updated software for in-house material flows. Its IT team, with a headcount in excess of 1,100, develops high-performance applications, and provides customers with in-depth advice on the intelligent combination of software with intralogistics equipment. SSI Schaefer’s broad IT offering, including its own WAMAS® and SAP products, delivers seamless support for all warehouse and material flow management processes. Solutions from SSI Schaefer improve the productivity and efficiency of customer organizations – not least through the highly precise monitoring, visualization and analysis of operational metrics for proactive intralogistics management.

SSI Schaefer offers highly sophisticated, turnkey systems. As an international player, it can deliver one-stop solutions to all four corners of the earth. Its comprehensive portfolio encompasses design, planning, consulting, and customer-specific aftersales services and maintenance.

SSI SCHÄFER

Fritz-Schäfer-Strasse 20

57290 Neunkirchen / Siegerland

Telefon: +49 (2735) 70-1

Telefax: +49 (2735) 70-396

http://www.ssi-schaefer.de

Marketing & Kommunikation

Telefon: +49 (2735) 70-252

Fax: +49 (2735) 70-382

E-Mail: melanie.kaempf@ssi-schaefer.de