Today, there are many commercially available Slicing software, most of which provide an automatic function for the creation of a G-code. As generating a G-code for 3D printing can be as easy as the user-friendliness of the Slicing software being used, the main success comes from having an appreciable knowledge about the materials-process-parameters relationship as well as the technical capabilities of the 3D printer. In the absence of such knowledge, the time needed to develop a printing profile, which delivers on excellent parts could take several months.

Overcome Challenges in the Generation of G-Code for 3D Printing with Apium

At Apium, we have established our industrial 3D printing solutions tailored to meet all our customer requirements. Our material development team put-in a great deal of time and effort to develop printing parameters for specialty polymers and metals. Upon attendance to our advanced trainings delivered by our Applications and Services Center engineers, you will already have your first successful print in hand on day 1.

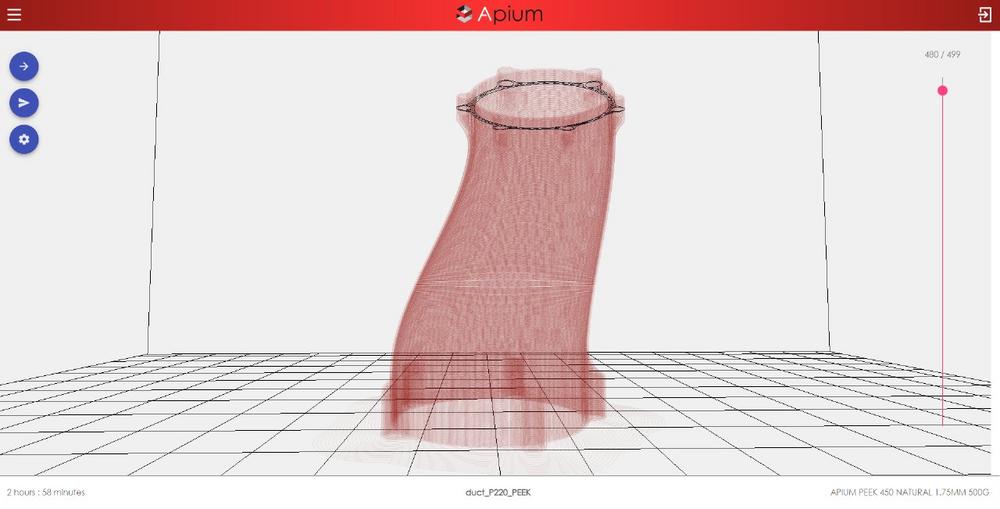

Together with the trainings, our engineers will be delivering material profiles for your future prints. These profiles contain the G-code file for your material of choice and ensure the preservation of the basic properties of the material being used together with the appropriate printing parameters. Our Apium P220 Series industrial high temperature 3D printers are designed for the processing of specialty materials. Fed with the appropriate G-Code for 3D printing, you can enhance your polymer processing capabilities significantly while reducing production costs and delivery lead times using the P220 printer. Apium P220`s open material system and filament tracking function will allow you to save your printing parameters as well as avoid trial and error for your future prints.

Contact our Apium experts to learn more about material profiles, Apium`s advanced trainings and best-in-class industrial 3D printing solutions.

We research, develop and produce Fused Filament Fabrication 3D printing filaments made from high performance polymers along with 3D printers to process them. After intensive research, we became the first company worldwide able to make PEEK (poly ether ether ketone) printable with the FFF 3D printing technology. As pioneers, we assure the best and most reliable print quality on the market. With our expertise and experience in practical applications, together with basic research, we have a unique competence center for small and medium enterprises from industries that use high performance polymers for the most demanding environments and applications.

With our strong core-competencies we strive to become the largest technology supplier of high performance filament materials and 3D printers for FFF 3D printing technology within the European market. Our goal is to set the industry standard in terms of quality and reliability at FFF 3D printing of high performance polymers. As a competence center we claim on the legitimacy to be present on the market and to take over a long-term leading role. Through our know-how and our expertise in the field of FFF 3D printing we assure our customers the highest quality and the best service.

Apium Additive Technologies GmbH

Siemensallee 84

76187 Karlsruhe

Telefon: +49 (721) 13 20 95 0

Telefax: +49 (721) 13 20 95 77

http://www.apiumtec.com/

Head of Marketing and Quality Management

Telefon: +49 (721) 6803087-0

E-Mail: pinar.karakas@apiumtec.com

![]()