Since its establishment in 1978 Esquel Group has developed into a high-performance company and produces 24.000 tons of cotton knit fabric and 130 million meters of yarn-dyed cotton woven fabric each year. The group has established a vertical supply chain, which means that everything from raw cotton, yarn spinning, fabric production and finishing, garmenting as well as packaging is controlled by Esquel. In this way highest quality standards can be guaranteed. Furthermore Esquel also occupies a leading market position in advanced textile technology, fair employment conditions and, above all, commitment to sustainability. In order to become a ‘green player’ along the entire supply chain, a strong corporate culture and reliable partners are required. For almost 30 years now, Esquel is trusting in the machines and technology of Mahlo GmbH + Co. KG. The German machine manufacturer is the world market leader in weft-straightening machines as well as quality and process control systems.

Controlling the fabric

Along the entire production process knitted as well as woven fabrics are permanently subject to distortion, tension and elongation, which need to be controlled and corrected. Therefore Esquel has invested in several fully-equipped Orthopac RVMC-15 automatic weft-straighteners from Mahlo. “The scanning system detects and analyses the regular basic structure of the weft threads, courses or rows of tufting. It automatically adapts the control system to a wide variety of textiles, even with the most complicated fabric structures”, explains Mahlo’s Sales Director Thomas Höpfl.

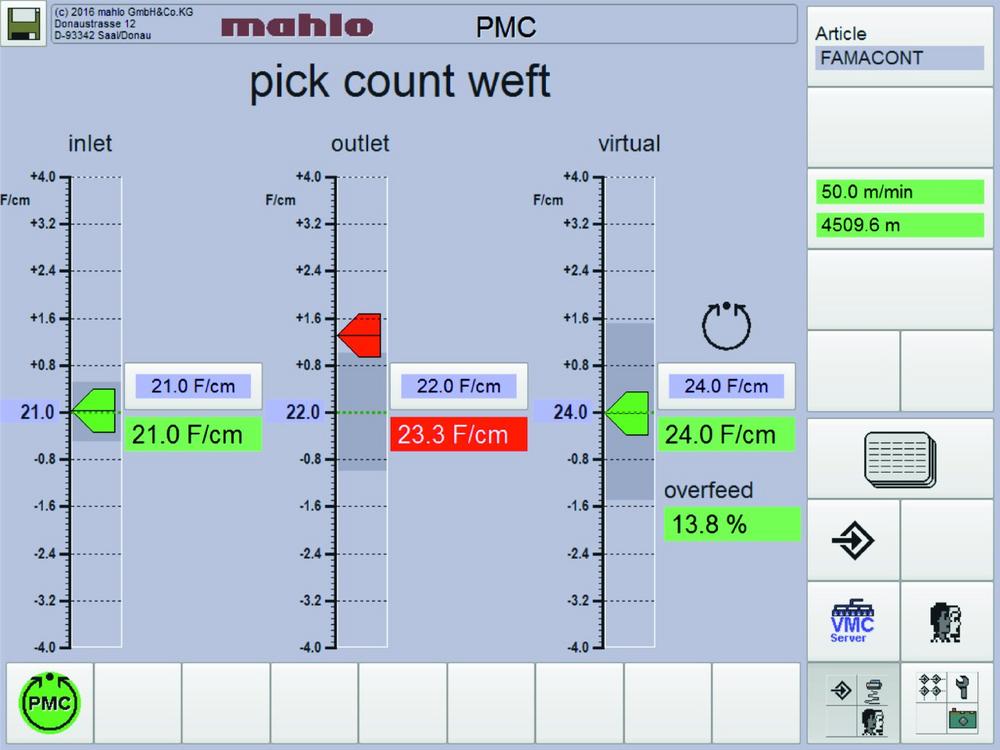

And in order to stabilize the thread density of their knitwear, Esquel has decided in favour of Famacont PMC-15 thread counting system. The latest development from Mahlo determines the yarn and stitch density with the greatest precision using digital signal processing. A sensor detects the thread density before the infeed of the stenter frame and controls automatically the over-feed in correlation to the chain speed. This enables Esquel’s production team to keep the thread density always constant and thus to obtain also information on the basis weight of the fabric, which is an important factor especially for knitwear, as it is sold by weight. Esquel Group is also using the Optipac VMC-15 process control system to determine other key parameters such as humidity and temperature in their production lines. The versatile Optipac system enables the textile manufacturer to enhance their fabric quality and to optimize their productivity, while at the same time reducing significantly the energy consumption during the production process. In this way Esquel can ensure high-quality standards and achieve a sustainable production.

Several decisive elements

The long cooperation with the German machine manufacturer was also influenced by other factors. Mahlo and Kuantex, the local Chinese partner, have always provided the Esquel Group with an optimum in technical support and after sales service. “The best possible technical support and know-how transfer is our priority. Thanks to numerous service stations worldwide, our customers can reach us quickly and easily. This is expected from an industry leader” emphasizes Höpfl. Esquel has been building on this expertise for over 30 years and further projects are also planned for the future.

Mahlo GmbH + Co. KG

Donaustr. 12

93342 Saal/Donau

Telefon: +49 (9441) 601-0

Telefax: +49 (9441) 601-102

http://www.mahlo.com

Marketing & Media Relations / Marketing und Öffentlichkeitsarbeit

Telefon: +49 (9441) 601-115

E-Mail: stephanie.marchsreiter@mahlo.com