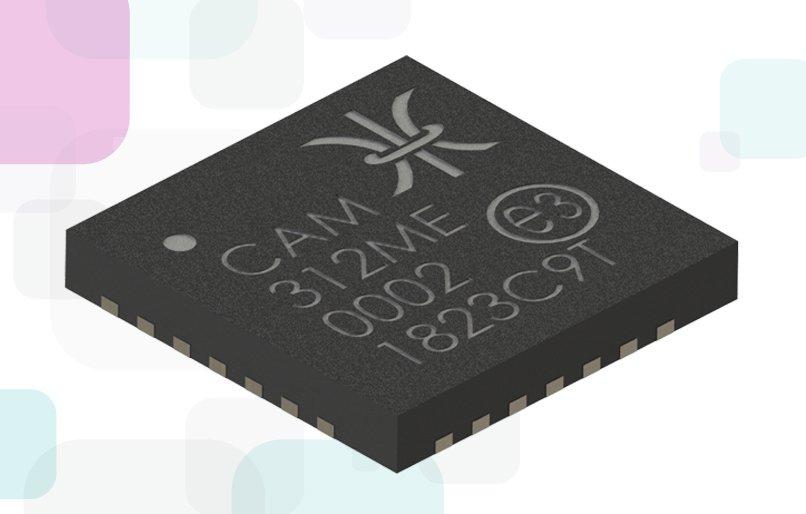

The CAM312 builds on CambridgeIC’s existing family of position measuring ICs, used in a wide range of applications for nearly a decade. These are a highly effective alternative to traditional position sensing approaches such as optical encoders or Hall encoders. CambridgeIC offers the performance of an optical sensor without the fragility, and the convenience of a Hall sensor in geometries where Hall sensors are not usable.

The chip connects to resonant inductive sensors built from PCBs, which not only improves robustness but also simplifies mechanical design and manufacture. Using a contactless target on the moving part, both linear and rotary (angular) positions can be measured, cost effectively and with high precision.

The latest generation of IC provides excellent responsiveness, with up to 2000 position samples per second, 200us Group Delay and a fast SPI interface. This rate of measurement allows for refined and repeatable control of fast moving parts in machines, even in harsh environmental situations. An automotive variant is available for operation up to 150°C.

By taking inputs from two simple sensors, the CAM312 also bears down on costs and complexity in designs, and allows multi-axis measurement of critical parts.

Applications will be in industrial valves, robotics and automotive applications. These require precision, no wear, stability over temperature, immunity to dirt and contamination, and tolerance of large gaps and misalignment between target and sensor.

A CAM312 Development Board is available.

For more information (and to obtain a data sheet) visit www.mev-elektronik.com. Or visit MEV’s stand at Embedded World. (Hall 3, booth 341).

About Cambridge IC:

CambridgeIC develops integrated circuits for sensing the precise position of moving parts in machines. We specialise in resonant inductive position sensing, and our team has been leading the development of this technology for over 20 years.

Our customers are designers of electromechanical products seeking an innovative edge. Resonant inductive technology helps simplify their product design and manufacture. Position sensors are built from conventional PCBs, so that they are accurate, robust and manufacturable at low cost. Founded in 2007, CambridgeIC has developed single chip processors and a set of standard sensor designs and integration tools. These help customers embed resonant inductive sensing inside their products, by drawing on modular and well proven components.

CambridgeIC’s head office is close to the centre of Cambridge UK, with partner companies and associates based in the US and Germany.

MEV Elektronik Service GmbH is a distributor/ stocking rep. and manufacturers‘ representative for electronic components, modules and systems. Special emphasis is placed on optimum technical service and consultation by 15 engineers to support the customers in Germany as well as in Central and Eastern Europe, while concentrating on state-of-the-art applications in leading market segments.

Our in-house laboratory and demonstration rooms where the best possible technical solutions can be worked out together with the FAEs in particular in the fields of power management, display technology and optoelectronics are at our customers‘ disposal.

Apart from the design-in oriented distribution, MEV focuses also on logistics concepts and services precisely adapted to individual customer needs, the open, honest and reliable partnership being the basis of the successful cooperation with customers and suppliers and within the team.

MEV Elektronik Service GmbH

Nordel 5a

49176 Hilter a.T.W.

Telefon: +49 (54) 242340-0

Telefax: +49 (54) 242340-40

http://www.mev-elektronik.com

Product Line Manager

Telefon: +49 (5424) 2340-57

Fax: +49 (5424) 2340-40

E-Mail: ggandolfo@mev-elektronik.com