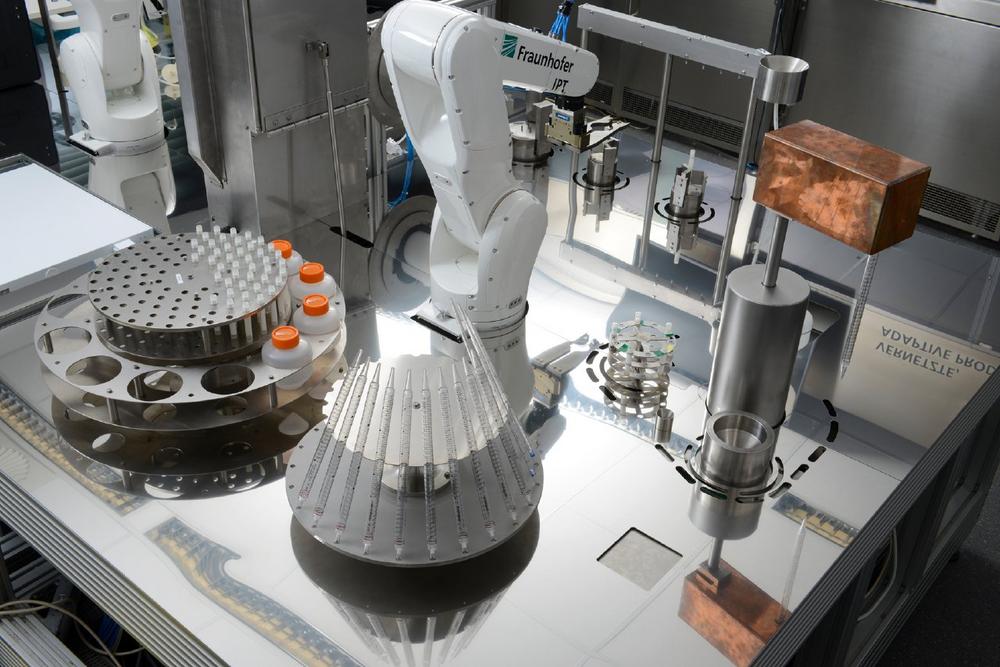

The Autostem platform concept has been designed as a user-oriented, closed, automated system to provide an efficient pipeline for the delivery of large numbers of therapeutic cells (mesenchymal stromal cells or MSCs). The process starts with a bone marrow donation, taken from the hip bone of a donor using a novel suction device developed to improve the patients’ comfort and yield. The bone marrow can be transferred in a sterile manner into the Autostem production line, where a robotic arm supports the isolation of MSCs from the bone marrow. The production line also includes capacity for real-time process management, monitoring of cell quality and environment and maintenance of the bio-reactor.

Flexible, automated cell production platform with related software and fully integrated functional modules

This entire process involves no hands-on human operations. While the system is of course monitored by scientific staff, the cell production process is entirely automated. This removes much of the risk of error or contamination, so that the pipleline will generate large amounts of high-quality cells, suitable for use in therapy. In addition to the novel pipeline itself, other innovations include tailored sensors that provide real-time in-process monitoring during production. Commercially available sensors track dissolved oxygen, pH and temperature, but the Autostem team have developed additional sensors to also track glucose, lactate and ammonia.

The platform represents a fully equipped, automated laboratory which will soon be working in a completely environmentally controlled area and is capable of isolating and expanding MSCs autonomously in a full end-to-end, adaptive process. Its modular and highly integrated design combines state-of-the-art laboratory equipment with novel technological developments: The pipeline allows for close monitoring and control of production and environmental parameters and paves the way towards sophisticated production schemes that are adaptive to cell behaviour. In this way the Autostem platform has been built to deliver a significant advance towards the routine clinical application of cell therapies in the future.

Exploring commercial perspectives of the project outputs

The Autostem team which has been working together in the project represents a wealth of experience in regenerative medicine, automation and robotics, bio-reactors and cell production, regulatory affairs and quality control, over more than ten years. The project began on 1 January 2016 and finished successfully on 31 December 2018. Finally, the researchers have been biologically validating the cells that had been produced in the project in vitro and in vivo, in order to ensure the clinical-relevance of the product.

As the prototype of the Autostem platform has been finished now, more work will be needed to allow for direct clinical use in patients, so the next steps will be exploring the markets for the project outputs. New knowledge about MSC selection and expansion, bioreactor systems, sensor technology and MSC action has been gained, which will present opportunities for further research and collaboration.

“The project is paving the way towards the cost-effective manufacture of MSCs and other therapeutic cell products in the future. Ultimately, this will benefit patients, clinicians and health systems, yielding wider societal and economic benefits”, says Dr. Mary Murphy of the National University of Ireland, Galway, Coordinator of the Autostem project.

List of international Autostem research partners

- National University of Ireland, Galway, Ireland

- Universita Degli Studi di Genova, Italy

- Fraunhofer Institute for Production Technology IPT, Germany

- University College Cork – National University Of Ireland, Cork, Ireland

- Pintail Ltd, Ireland

- Crospon Limited (now part of Medtronic), Ireland

- Zellwerk GmbH, Germany

- Cell Therapy Catapult Limited, United Kingdom

- Aston University, United Kingdom

- Orbsen Therapeutics Limited, Ireland

AUTOSTEM has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement no 667932. The material presented and views expressed here are the responsibility of the author(s) only. The EU Commission takes no responsibility for any use made of the information set out

More information

Das Fraunhofer-Institut für Produktionstechnologie IPT vereint langjähriges Wissen und Erfahrung aus allen Gebieten der Produktionstechnik. In den Bereichen Prozesstechnologie, Produktionsmaschinen, Produktionsqualität und Messtechnik sowie Technologiemanagement bietet das Fraunhofer IPT seinen Kunden und Projektpartnern angewandte Forschung und Entwicklung für die vernetzte, adaptive Produktion. Das Leistungsspektrum des Instituts orientiert sich an den individuellen Aufgaben und Herausforderungen innerhalb bestimmter Branchen, Technologien und Produktbereiche, darunter Automobilbau und -zulieferer, Energie, Life Sciences, Luftfahrt, Maschinen- und Anlagenbau, Optik, Präzisions- und Mikrotechnik sowie Werkzeug- und Formenbau.

Fraunhofer-Institut für Produktionstechnologie IPT

Steinbachstraße 17

52074 Aachen

Telefon: + 49 241 8904-0

Telefax: + 49 2 41 8904-198

http://www.ipt.fraunhofer.de

Presseansprechpartner

Telefon: +49 (241) 8904-180

Fax: +49 (241) 8904-6180

E-Mail: susanne.krause@ipt.fraunhofer.de

Geschäftsfeldleiterin

Telefon: +49 (241) 8904-571

E-Mail: jelena.ochs@ipt.fraunhofer.de