Machine Vision

With a comprehensive portfolio of machine vision products Balluff provides the answer for the rapidly increasing requirements in production in terms of flexibility, productivity and quality. This product scope covers a broad range of applications in object detection, identification and quality assurance – scalable with single to multiple camera solutions. Another great feature: Image processing experts only need to be called in for truly intricate situations. The majority of tasks can be solved much more simply thanks to a well-thought out user interface.

Digitization in fluid technology

Traditional fluid technology drives are turning into intelligent, networked, highly flexible solutions. Sensors handle any possible task and use open interfaces to make their digital data available. The sensor data are a prerequisite for digitization of the overall system.

With their BMP series Balluff now has a new intelligent distance sensor for fluid technology applications in their product range. This magnetic, non-contact and wear-free sensor continuously detects the absolute position of a piston, is compatible with virtually all cylinder types and is quickly installed. In addition to the absolute position signal, it also transmits a variety of data for condition monitoring over the IO-Link interface. It can be seen in action at Booth 19 in Hall 23 (IAMD)

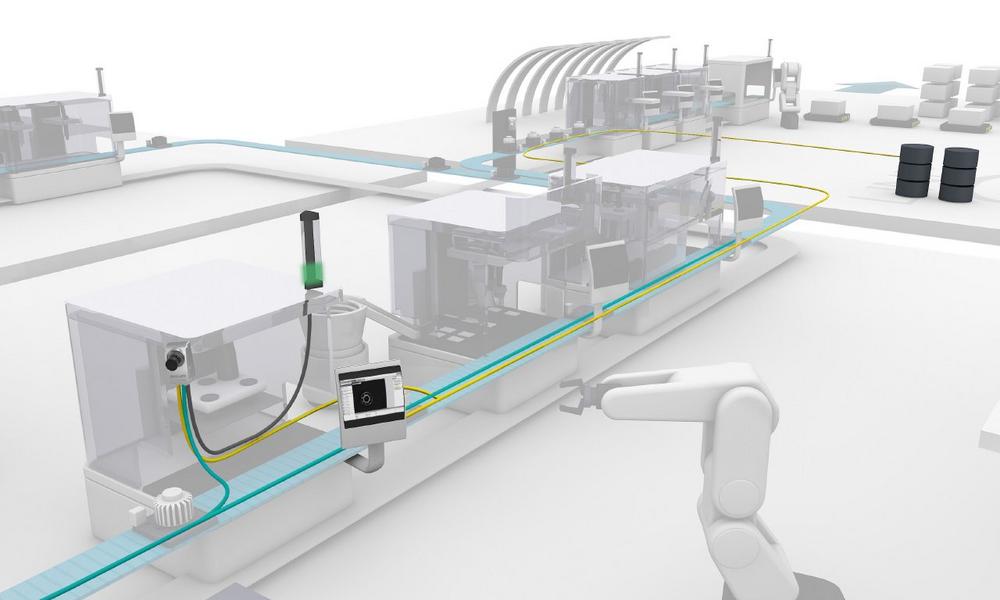

Modules for Industry 4.0

Tool ID is a clear and practical example for how Industry 4.0 easily finds its way into production. By means of industrial RFID, it makes the use of metal-cutting tools traceable, ensures their optimal utilization, and supports predictive maintenance.

Intelligent sensors

Balluff will also highlight all the advantages that intelligent IO-Link sensors offer the user. The new series BOS Q08M and BOS R01 mini-sensors feature not only reliable object detection with the smallest possible footprint, their scanning range and hysteresis can be set simply and precisely over the IO-Link interface without time-consuming adjustment of the sensor-to-object distance. In addition, these IO-Link sensors provide information such as diagnostics data and number of operating hours.

Another example is a newly developed optical multi-function sensor. It combines four photoelectric sensor principles in one enclosure which can be easily switched via IO-Link to choose the most reliable detection method for the respective application. Its detection signals are prepared and pre-processed in the sensor. This relieves the burden on the system controller and reduces data volume on the fieldbus systems.

Safety

With their "Safety over IO-Link" Balluff will show how automation and safety can be efficiently combined in one overall system. The world’s first integrated safety solution via IO-Link and PROFIsafe is open to the sensor level while being simple to install and retrofit. Both Balluff safety components and safety devices from other manufacturers can be connected to the Profisafe safety hub using M12 standard cable.

Balluff at the Hanover Exhibition:

Hall 9, Booth F53

Founded in 1921 in Neuhausen a.d.F., Balluff employs 4000 people worldwide and represents innovative technology, quality and cross-industry experience in industrial automation. As a leading sensor and automation specialist, the family-owned company in its fourth generation offers a comprehensive range of high-quality sensor, identification, networking and software solutions.

In 2017, Balluff Group reported revenues of around 459 million euros. In addition to the main headquarters in Neuhausen a. d. F., Balluff has sales, production and development locations around the world and can boast 37 wholly owned subsidiaries and other representatives in 68 countries. This guarantees customers rapid worldwide availability of products and high consulting and service quality on site.

Balluff GmbH

Schurwaldstr. 9

73765 Neuhausen

Telefon: +49 (7158) 1730

Telefax: +49 (7158) 69154

http://www.balluff.com

Pressekontakte /PR, Presseansprechpartner

Telefon: +49 (7158) 173-418

Fax: +49 (7158) 173-500

E-Mail: detlef.zienert@balluff.de