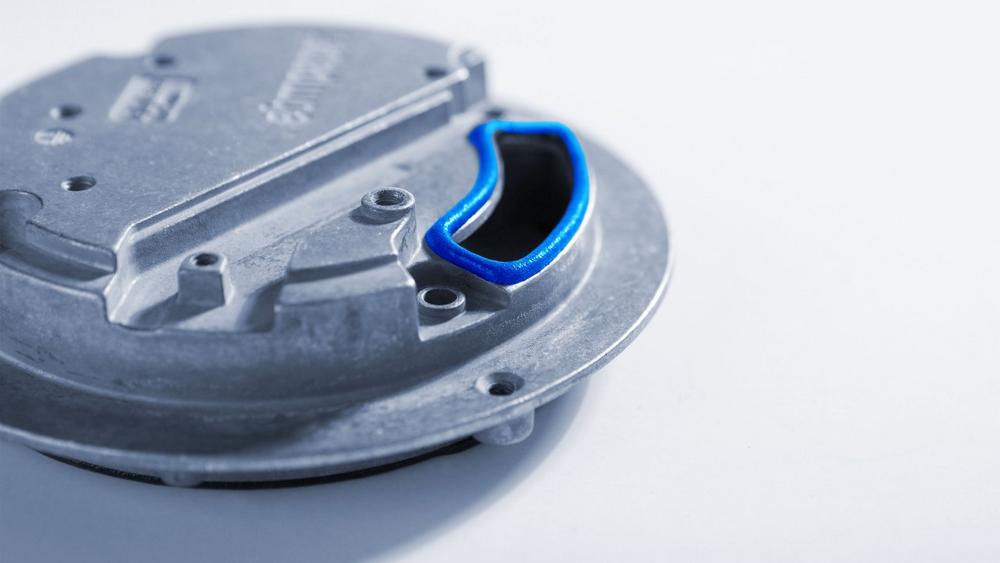

These predominantly closed-cell, soft sealing gaskets combine basic technical requirements for use in e-mobility applications – such as high tensile strength / fatigue strength and special tightness requirements even with considerable over- and underpressure – with the economic manufacturing and processing advantages of polyurethane (PUR) while maintaining closest tolerances, even in large-scale production.

Expertise in development

To ensure that the material and thus the foam seals can show all their advantages in applications such as battery covers, plug seals or seals for covers or housings of all kinds, it is important to involve the development supplier at an early stage in the design phase, especially in projects in the field of e-mobility: the expertise gained on decisive parameters – such as space-saving dimensioning, necessary tightness (protection against dirt / moisture / noise transmission), expected degree of deformation, seal heights, installation details (i.e. minimum installation forces), etc. – does not only have a significant influence on the long-term performance of the entire unit, but also on the costs of installation, subsequent maintenance or possible replacement.

Expertise in material combinations

As one of the leading manufacturers of 1K-PUR foam seals including the necessary experience in the entire value chain, CeraCon is your qualified partner. From the needs-based selection of the specific sealing material and support in the process-optimized design of the components to be sealed to the development of prototypes / pre-series and series production in contract gasketing plants in Germany and abroad. Thus, in addition to the original task, such as tightness against dirt / moisture or noise insulation, the specific characteristics of the materials with which the foam sealing gaskets should be combined can be included in the development right from the beginning. For example, due to intensified use of lightweight constructions, a clear trend can currently be observed from the familiar cast or aluminium housings to particularly filigree metal lightweight construction or plastic solutions to which the predominantly closed-cell PUR foam seals from CeraCon Sealing systems are already adapted.

The German mechanical engineering company CeraCon GmbH was founded in 2000 and has got its head office in Weikersheim/Baden-Württemberg. Currently, CeraCon has got about 200 employees in different business areas working in Germany and abroad.

The core business of CeraCon is selling, designing and manufacturing of standardized and customer-specific machines. The division "Sealing systems" is responsible for processing and applying foam gaskets directly to the components to be sealed as well as for developing and producing the corresponding adhesives and sealing compounds. The division "Thermal systems" comprises the heat treatment and buffering of components in horizontal and vertical design.

Furthermore, CeraCon offers contract gasketing service and is able to apply foam to customer components in large or small series.

Target industries are the automotive sector, the respective suppliers, the electrical and electronics industry as well as the white goods sector. More than 70 % of the company turnover is achieved abroad.

CeraCon GmbH

Talstr. 2

97990 Weikersheim

Telefon: +49 (7934) 9928-0

Telefax: +49 (7934) 9928-28

http://ceracon.com/

Leitung Öffentlichkeitsarbeit

Telefon: +49 (7934) 9928-651

E-Mail: baerbel.haas@ceracon.com

![]()