“The mirror finish on the high-gloss version is just like a polished lacquer surface, and gives the colour depth as if behind a pane of glass,” is how Thomas Tossmann, Business Unit Manager at RENOLIT DESIGN, describes the visual effect. The touch is just as authentic: the high-gloss surface feels just as smooth as it looks – it is endlessly smooth, even when lightly rubbed. And the super-matt texture feels emphatically flat, with visual and tactile appeal in equal measure.

PET laminates combine their design qualities with excellent formability and durability. They are scratch-resistant, unaffected by fingerprints and easy to clean. These material properties mean that it is possible to create furniture fronts and caravan equipment which can withstand knocks and bangs, and retain their beautiful finish for a prolonged period. The RENOLIT PET Laminate 2D and 3D designs are both available from stock.

Interplay of materials

Mixing materials is currently a hot topic in the world of interior design, colour schemes and surfaces. Distinctive wood finishes and super-matt lacquered laminates harmonise, for instance, with the new reproduction marble finishes “Harley” and “Carrara” which RENOLIT had also brought along to the trade fair. By contrast, the material mix in the “Concrete Illusion” print is in the finish itself. Two materials flow into one another: “A wafer-thin concrete surface covers a textile weave, allowing the grain of its fibres to gleam through, so that a mix of materials is created within one surface,” is how designer Claudia Hiepel describes this interesting approach.

New chapter in lightweight construction

The new thermolaminate collections set the scene for sculpted furniture projecting three-dimensionally from the walls, a caravan module with kitchenette, wet room and seating area demonstrate the versatility of RENOLIT GORCELL base material combined with RENOLIT ALKORCELL in contemporary finishes and on-trend colours.

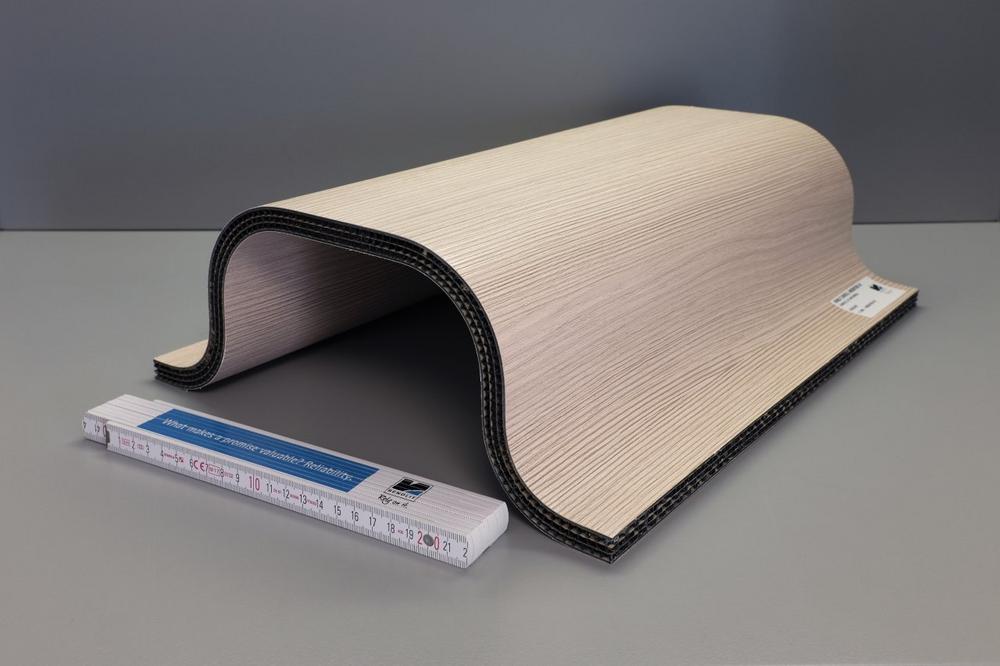

The company is launching a new chapter with innovative core materials RENOLIT GORCELL veneer-flex and RENOLIT GORCELL super-flex. These materials are extremely light and rigid, with less than half the density of balsa wood, for instance. They are also flexible, can be formed to an internal radius of up to 20 millimetres – regardless of the direction of bend – and are 100% water-resistant. Coated with RENOLIT CORK-STOK, RENOLIT WOOD-STOCK or CPL/veneer, these new materials are ideal for interior fittings in caravans or yachts, for example, as well as for wet and humid areas.

Just like wood: printed finish with synchonised pore

In striving for the most natural possible effect in decorative wood finishes, synchronised pore technology remains the ultimate choice. For RENOLIT’s latest creation for 3D laminates, the striking “Halifax” oak finish, this technique helps recreate the interplay of knots, cracks and ribbon stripes in the wood. A visual as well as tactile gnarled effect is created, which perfectly answers the quest for a natural and authentic look in the living room, particularly in the “Nature” shade. The same applies to the “White” shade, and the dark “Tobacco”, which are equally well suited to door finishes. The pale tones of “White” will recreate a light Scandi decor in living rooms or offices, as well as suiting interior fittings.

And “Sweet Chestnut” pulls out all the stops, with its harmonious interplay of printed and synchronous pore finish. The pattern for 2D laminate runs three-dimensionally on different levels, the growth rings resemble steps and give the printed image a depth which looks extremely natural. Every level has its own dimension – ribbons, stripes and knotted effects alternating in the grain. Sweet Chestnut brings an elegant yet rustic feel to living and sleeping areas, and is available in Chestnut, Bleached, Limed, Dark Grey and Black shades.

The open grain of the brushed chestnut comes into its own particularly through the grey shades. The black option, by contrast, is reminiscent of the charred finish of “Yakisugi” – a traditional Japanese method of preserving wood. Sweet Chestnut reflects the special depth of colour and texture which carbonisation gives the wood, and also inspired the colour scheme of RENOLIT’s Interzum stand.

The RENOLIT Group is an international company specialising in high-quality films, panels and other synthetic products. With more than 30 branches in over 20 countries, and sales amounting to 1,031 billion Euros in 2018 the company based in Worms, Germany, is one of the leading processers of polymers in the world. Over 4,700 employees have been constantly developing know-how throughout the company’s 70-year history.

www.renolit.com Twitter Facebook Linkedin

RENOLIT SE

Horchheimer Str. 50

67547 Worms

Telefon: +49 (6241) 303-0

http://www.renolit.com

Corporate Communications

Telefon: +49 (6241) 303-1175

E-Mail: matthias.mueller@renolit.com