Sigma Smart Air offers much more than current frameworks for servicing compressed air systems, in which maintenance is performed either upon request or at established intervals. In this case, there is always the risk that service will be performed too early or too late, depending on the actual operating hours – both of which result in additional costs and the risk of downtime for the operator.

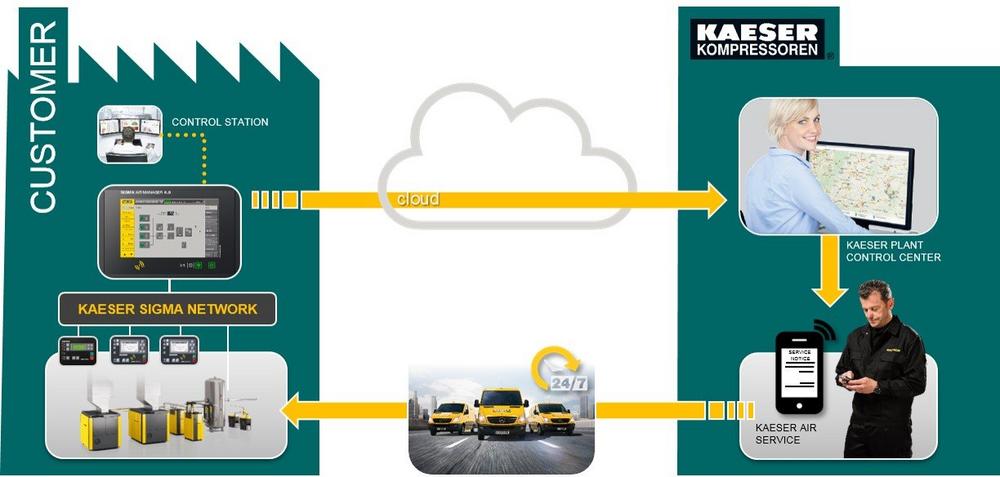

With Sigma Smart Air, Kaeser Kompressoren offers a service that delivers predictive maintenance and maximum energy efficiency, while guaranteeing the availability of the compressed air supply – far beyond what could be expected of any system in the past. In order for users to benefit from real-time display of operating, service and energy data for the compressed air station, it must be ‚intelligent‘, in other words, connected to the Ethernet-based Sigma Network (or Profibus) and controlled by the Sigma Air Manager 4.0 master controller.

Sigma Smart Air offers the option of creating the above conditions for existing and new compressed air systems, without the need for further investments.

Sigma Smart Air combines the powerful feature of real-time data management with Kaeser’s expertise and predictive maintenance, making it possible to maximise the compressed air supply whilst minimising life-cycle costs without additional investments.

How does Sigma Smart Air work?

The physical meets the virtual world within the framework of a structural model in which the specific compressed air system, configured according to the operator’s requirements, is represented virtually by a digital twin. Real-time availability of operating data makes it possible to monitor the ‚health‘ status of a compressed air station. This means that potential faults can be detected in advance and appropriate maintenance measures automatically initiated at the right time. Ultimately, operators benefit from significantly reduced compressed air production and operating costs, as well as improved compressed air availability.

Sigma Smart Air saves costs otherwise required for procurement, training, logistics, service and in-house service staff. Sigma Smart Air also provides maximum cost transparency throughout the compressed air system’s entire life-cycle.

This is guaranteed by a service price, based on the volume of compressed air that is actually produced and adjusted flexibly to additional or reduced demand, similar to your electricity bill. Fixed prices over long periods of time facilitate your advance planning.

Moreover, Sigma Smart Air includes monitoring of key figures such as service costs, reserves and specific power, enabling sophisticated energy and life-cycle management of the compressed air station throughout its entire service life. Always up-to-date, the energy data figures from a single source also lay the foundation for energy management as per ISO 50001.

Established in 1919 as a mechanical engineering workshop, Kaeser Kompressoren is a family-owned business and today is one of the world’s leading compressor manufacturers and compressed air systems providers. Kaeser’s production centres are located in Coburg (main plant) and Gera, Germany. The company has approximately 6000 employees worldwide.

Kaeser’s comprehensive product range comprises stationary and portable rotary screw compressors, stationary and mobile reciprocating compressors, vacuum pumps, rotary blowers, filters, dryers, air tools and accessories. Furthermore, Kaeser’s state-of-the-art compressor control systems with advanced IT technology take compressed air efficiency to the next level and beyond. Both users and the environment therefore benefit from the consequent energy-savings.

Subsidiaries and authorised partners in over one hundred countries ensure that users are able to enjoy all of the benefits that the very best in compressed air engineering has to offer. Key markets include the EU, the United States, Latin America and the Asia-Pacific region. Kaeser owes its enviable reputation not only to the exceptional efficiency and quality of its products, but also to its reliable field service. More recently, the other industry-leading services offered by the company – such as operator models for compressed air stations, concepts within the framework of Industry 4.0 and predictive maintenance – have increasingly moved to centre stage.

Kaeser’s many years of strong growth and expansion are directly attributable to its passion for innovation and strict quality standards. Both are driven by the hard work and dedication of its employees, whose expertise, combined with ongoing professional development, keep them attuned to the very latest technology. The company’s opening-up of key global markets in recent years has also created many additional jobs and secured existing ones, both in Germany and around the world.

The company is headed by Thomas Kaeser, Dipl.-Wirtsch.-Ing, grandson of the company’s founder, and Tina-Maria Vlantoussi-Kaeser, Dipl.-Wirtsch.-Ing.

Brief company history:

Founded: Coburg 1919

Trade name: Kaeser Kompressoren

Founder: Carl Kaeser senior

Executive management: Thomas Kaeser, Dipl.-Wirtsch.-Ing.,

Tina Maria Vlantoussi-Kaeser, Dipl.-Wirtsch.-Ing.

Products: Reciprocating and rotary screw compressors ranging from 0.18 to 515 kW, portable rotary screw compressors, high-pressure and dry-running compressors, compressor control systems, vacuum pumps, rotary blowers, air filters and tools, refrigeration & desiccant dryers, as well as compressed air system accessories and services.

Turnover (2018 Kaeser Kompressoren SE): Approximately EUR 1 billion

Employees:

Worldwide: Approx. 6000

Apprentices: Approx. 300

Apprentice positions per year (since 2016): 120

Production centres: Coburg (main plant), Gera

Branch offices: 8 regional offices throughout Germany

Worldwide sales partners: Represented in over 100 countries by Kaeser-own branch offices and exclusive authorised partners

KAESER KOMPRESSOREN SE

Carl-Kaeser-Str. 26

96450 Coburg

Telefon: +49 (9561) 640-0

Telefax: +49 (9561) 640-130

http://www.kaeser.com

Pressestelle

Telefon: +49 (9561) 640-452

Fax: +49 (9561) 640-129

E-Mail: daniela.koehler@kaeser.com