Quiet, low-vibration, and low-friction linear travel are essential in sophisticated mechanical engineering systems. This applies to automated applications in metrology, as well as in the semiconductor, biotech, medical devices, machine tools, laser processing, and many other branches of industry. SCHNEEBERGER provides high-quality MONORAIL guideways to serve as the perfect basis for such applications. The Swiss company offers many different versions of its magneto-resistive measuring system to always supply the appropriate solution to meet the stringent requirements of precision distance measurement.

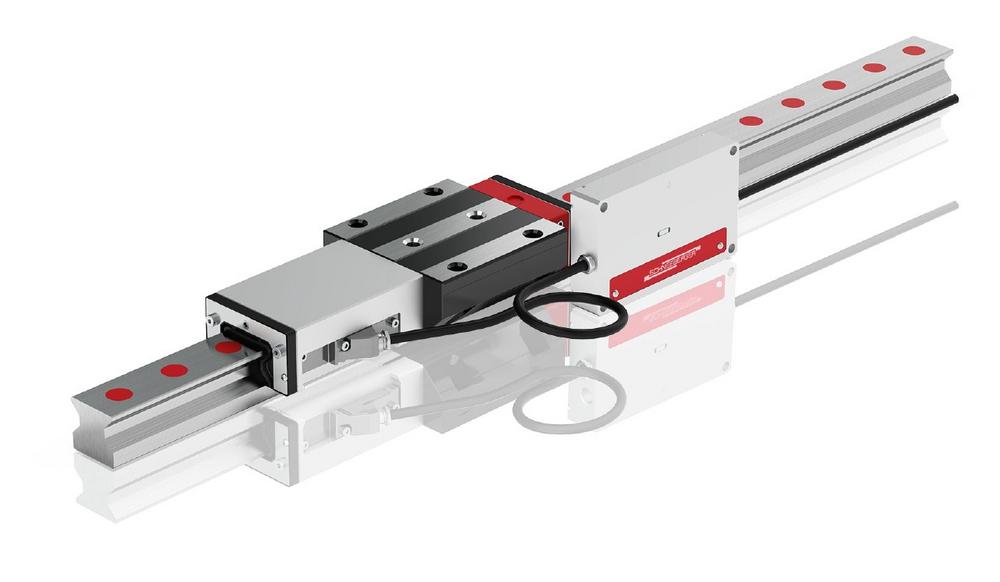

The MONORAIL AMS 3B, for example, is an integrated magneto-resistive distance measuring system based on the MONORAIL MR roller profile guideway. This integration results in axes with a compact design and distance measurement and guideways which are especially suitable for use in machine tools. No additional assembly or adjustment of the measuring system is required by the operator; It also delivers cost savings in the design, manufacture, and maintenance of the equipment. And, by using the AMS 3B, accuracy and process reliability are improved.

The AMSA 3B analog variant features a voltage interface of 1 Vss that connects to all conventional controllers and is the starting point for the AMSD 3B digital version. The latter has a digital incremental interface that references different resolutions and permits system adaptation for controllers with different input frequencies.

SCHNEEBERGER developed the AMS 4B integrated magneto-resistive measuring system for the MONORAIL BM ball guideway. In terms of measurement technology, it corresponds to the AMS 3B and offers the same advantages in cost savings, accuracy, and reliability. AMS 4B products are the preferred choice if there is a great demand on the dynamic characteristics of the axes and rate of travel.

In summary, the MONORAIL AMSABS with an absolute interface is an integrated magneto-resistive measuring system developed on the basis of the measuring systems mentioned above. It adds new features to the proven benefits and simplifies the operation of measurement systems in industrial environments. For example, since it uses absolute distance measurement, there is no longer any need for a reference run after switching on, which saves time and money during operation.

The AMSABS features an absolute interface for connection to SSI, SSI+SinCos and all Fanuc controllers. The Siemens DRIVE CLiQ®* and Mitsubishi interface have recently been added. The Siemens DRIVE CliQ interface is certified in accordance with SIL 1.

The latest development from SCHNEEBERGER in the field of integrated magneto-resistive measuring systems is the MONORAIL AMSA 3L, which is designed for building especially long axes on the basis of the MONORAIL MR roller guideway. SCHNEEBERGER also offers an integrated distance measuring system for combined guidance and measuring in very restricted spaces. The MINISCALE Plus system based on the MINIRAIL guideway has a resolution of 1 µm and can measure lengths as short as 1000 mm.

[1] DRIVE-CLiQ is a protected trade mark of Siemens

SCHNEEBERGER® operates worldwide as an established OEM supplier in a wide variety of sectors – from the solar, semiconductor and electrical industries to the machine tool and medical devices sectors, and beyond. The product and manufacturing program includes linear bearings and profiled linear guideways as well as measuring systems, gear racks, slides, positioning systems and mineral casting. A.MANNESMANN, headquartered in Remscheid, Germany, has been part of the SCHNEEBERGER Group since October 2017.werotec ag, headquartered in Reigoldswil, Switzerland, has also been part of the SCHNEEBERGER Group since early 2018. werotec ag’s core competence lies in precision grinding technology and in the complete production of anti-friction bearing rollers.

SCHNEEBERGER AG

St. Urbanstrasse 12

CH4914 Roggwil

Telefon: +41 (62) 91841-11

Telefax: +41 (62) 91841-00

http://www.schneeberger.com

Pressekontakt

Telefon: +41 (62) 9184-302

E-Mail: rosalia.haller@schneeberger.com