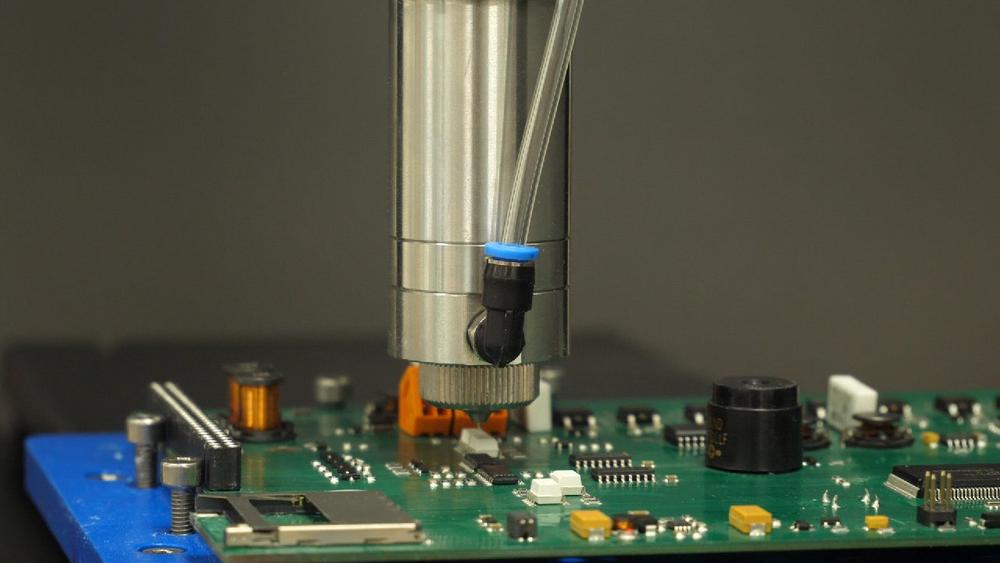

In a current feasibility study, preeflow tested the spray application of a filled Glob Top material: More precisely a DELO MONOPOX GE6515 adhesive. This highly viscous adhesive is used, for example, in the automotive industry for potting electronic components that are exposed to demanding environmental conditions. In particular these include high temperatures, but also aggressive materials.

The preeflow eco-SPRAY is the combination of a volumetric dispensing system – based on the eco-PEN Dispenser series – and a specially developed "low-flow spray chamber". On the one hand this makes it possible to spray a precisely defined quantity: With a precision of up to ± 1 %. On the other hand, very high viscosities can be processed, and even pasty materials can be sprayed. This makes the eco-SPRAY unique in the spray valve market. It enables continuous spraying at different traversing speeds, spraying of a precisely defined area with a precisely defined amount of material and high edge sharpness. With the eco-SPRAY spray dispenser, an efficient dispensing application was achieved in the dispensing tests – an alternative to needle dispensing.

Advantages of the spray application compared to the usual needle dispensers:

- Reduced material consumption

- Time-saving (no movement necessary in the Z-direction)

- Non-contact (no contact is made with the substrate, therefore no risk of damage)

You can see the results of the dispensing tests in the video: https://www.youtube.com/watch?v=DCzcD9fD5b8

Microdispensing in perfection!

preeflow® is a brand name powered by ViscoTec Pumpen- u. Dosiertechnik GmbH. ViscoTec primarily deals in systems required for conveying, dispensing, applying, filling and emptying medium to high-viscosity fluids. The headquarters of the technological market leader is in Töging (upper Bavaria, near Munich). In addition, ViscoTec has subsidiaries in the USA, in China, Singapore and in India and employs about 250 people worldwide. Established in 2008, preeflow® ensures precise, purely volumetric dispensing of liquids in the smallest of quantities. preeflow® products are appreciated worldwide, not to mention because of their unique quality – Made in Germany. An international distribution network offers professional service and support in all areas of preeflow® dispensing systems. The various fields of application include, among others, automotive, electrical and electronics industry, medical technology, aerospace, renewable energies, electrical and hybrid technology and measurement and sensor technology. The complete preeflow® portfolio can be easily integrated due to standardized interfaces. Worldwide more than 20,000 preeflow® systems are working in semi- or fully-automated dispensing applications to the user’s and customer’s complete satisfaction.

preeflow Microdispensing

Amperstraße 13

84513 Töging a. Inn

Telefon: +49 (8631) 9274-0

Telefax: +49 (8631) 9274-300

http://www.preeflow.com

Online & PR

Telefon: +49 (8631) 9274-404

E-Mail: melanie.hintereder@viscotec.de