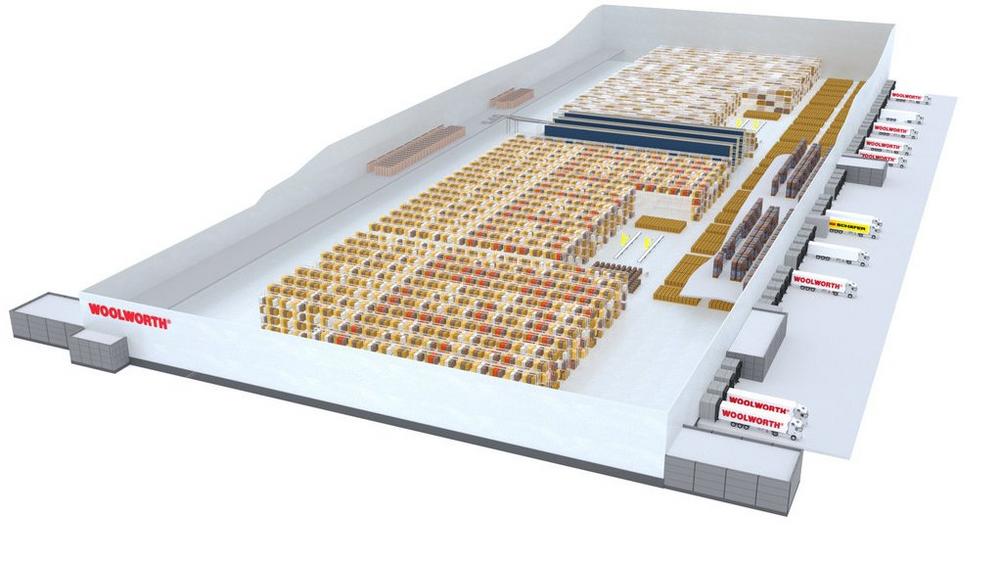

In the medium term, the traditional retail company, which sees itself as a local supplier of everyday consumer goods, would like to expand its nationwide store network from around 400 to 800 stores. The hub for the supply will be the new company headquarters in the industrial estate Unna/Kamen, directly at the A1 highway. The headquarters include an administration building and a new warehouse and distribution center with five halls. On an area of approx. 50,000 m², around 40,000 pallets will be stored in the SSI Schaefer longitudinal beam rack PR 600. Additionally, a static rack system R 3000 to archive files as well as a three-aisle miniload for double-deep storage with more than 29,000 bin storage locations will be installed. The SSI Schaefer logistics software WAMAS® controls the material flows. The system is operated by ERL Euro Retail Logistics GmbH and stores and prepares a wide range of home textiles, household supplies, fashion for women, men and children, decorating materials and drugstore products as well as stationary, notions and sweets for shipping.

Designed for continuing expansion

In August 2019, the gradual installation of the racks was started. The miniload will be installed starting from January 2020. It is scheduled to be launched in July of the same year. “Our new central warehouse provides sufficient capacity for future growth,” says Heinz Lutermann, General Manager ERL Euro Retail Logistics GmbH. “At the same time, we take advantage of a fast and secure provision of goods from the miniload and combine them with classic person-to-goods processes in the forklift-controlled pallet warehouse.” This ensures maximum delivery quality. All in all, about 8,000 items will be stored in the future. Approx. 2,100 of them in the miniload. This translates to a performance of about 16,500 of more than 250,000 store positions per day. “SSI Schaefer convinced us as a full-range supplier of manual and automated logistics solutions,” comments Mr. Lutermann on the reasons for choosing the logistics supplier.

Optimized material flow solution for store supply

In the future, the empty bins provided at the goods-in area are filled with goods at the four repacking work stations and are conveyed to the miniload after a contour and weight check. There, three storage and retrieval machines, type Schäfer Miniload Crane, are in charge of storage and retrieval processes. On the long side of the miniload aisles, a total of 2,178 dynamic channels are implemented for manual picking. The required items are taken from the corresponding dynamic channels until the order is complete and ready for shipping. A repacking and clearing station facilitates repacking remaining items from the pallet warehouse and e.g. processing items that are past their best before date.

The go-live date for the entire system is planned for July 2020.

The SSI Schaefer Group is the world’s leading provider of modular warehousing and logistics solutions. It employs approximately 10,500 people at its group headquarters in Neunkirchen (Germany), at eight domestic and international production sites, and at approximately 70 worldwide operative subsidiaries. Across six continents, SSI Schaefer develops and implements innovative industry-specific answers to its customers’ unique challenges. As a result, it plays a key role in shaping the future of intralogistics.

SSI Schaefer designs, develops and manufactures systems for warehouses, industrial plants, workshops and offices. Its portfolio includes manual and automated solutions for warehousing, conveying, picking and sorting, plus technologies for waste management and recycling. In addition, SSI Schaefer is now a leading provider of modular, regularly updated software for in-house material flows. Its IT team, with a headcount in excess of 1,100, develops high-performance applications, and provides customers with in-depth advice on the intelligent combination of software with intralogistics equipment. SSI Schaefer’s broad IT offering, including its own WAMAS® and SAP products, delivers seamless support for all warehouse and material flow management processes. Solutions from SSI Schaefer improve the productivity and efficiency of customer organizations – not least through the highly precise monitoring, visualization and analysis of operational metrics for proactive intralogistics management.

SSI Schaefer offers highly sophisticated, turnkey systems. As an international player, it can deliver one-stop solutions to all four corners of the earth. Its comprehensive portfolio encompasses design, planning, consulting, and customer-specific aftersales services and maintenance.

SSI SCHÄFER

Fritz-Schäfer-Strasse 20

57290 Neunkirchen / Siegerland

Telefon: +49 (2735) 70-1

Telefax: +49 (2735) 70-396

http://www.ssi-schaefer.de

Junior Project Manager CR & PR | Global Marketing

Telefon: +49 (2735) 70-9683

Fax: +49 (2735) 70-382

E-Mail: Annika.Nolte@ssi-schaefer.com

Senior Global Communications Manager / Global Marketing

Telefon: +49 (2735) 70-252

E-Mail: Melanie.Kaempf@ssi-schaefer.com

![]()