“With our 3DViewStation product family we allow you to translate all geometries into a smaller, faster and light weight representation. We support all major CAD systems such as: Catia, NX, Creo, SolidWorks, SolidEdge, Inventor and also neutral formats like: JT and STEP. In order to protect your IP (intellectual property), during data preparation process, we also allow you to slightly alienate geometries in a nearly invisible way. This ensures that the data is not useful (i.e. production of spare parts). In addition, you may also opt to automatically remove internal parts which may not be required on the machine.” said Kelly Baumann, KISTERS North America Business Development Manager. “For the HMI itself, we provide Desktop as well as Web based visualization solutions, which can be installed on every single machine or on a separate system for a complete machine cluster.”

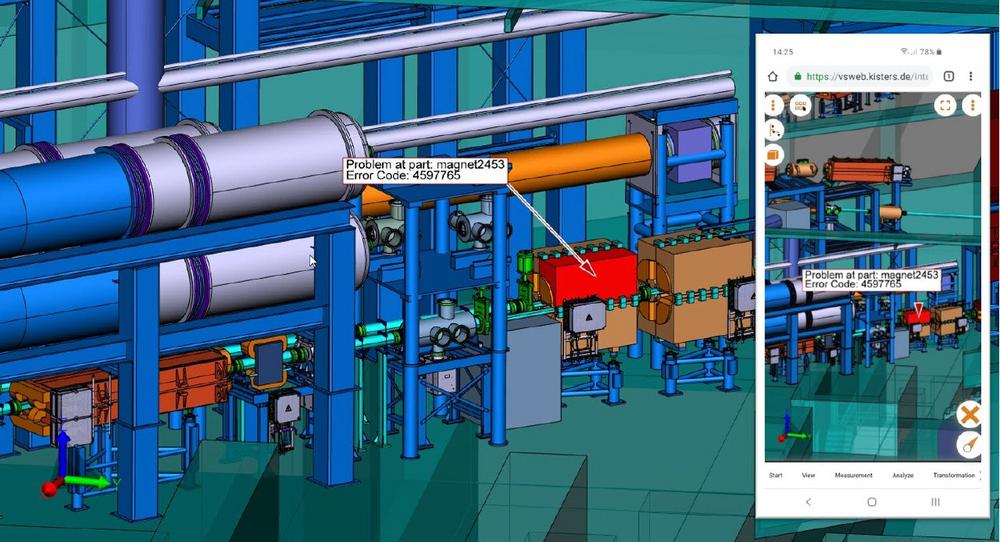

“As we now live in an IoT world, we demand more than simple error codes on the 3D model of the respective machine (i.e. for service staff alerts). When leveraging KISTERS 3DViewStation WebViewer users can now benefit by receiving: information about the customer, the machine and its error code, all on their smartphone. From there they can find information about where exactly the error occurred inside the machine and links to the potential error resolving procedures.” she added. “Customers as well as service staff can now easily order the correct spare parts as needed due to the fact that they will know the exact machine configuration. The results are even better when it has been maintained over a lifetime following the digital twin idea. Machine vendors might also benefit from virtual inspections in real size by leveraging our 3DViewStation VR-Edition, it is even able to handle machines consisting of millions of parts.”

Known for its modern user-interface, high performance viewing, advanced analysis and integration capabilities into leading systems, 3DViewStation ships with current and mature importers for a broad range of 3D and 2D formats including i.e. Catia, NX, Creo, SolidWorks, SolidEdge, Inventor, Revit, JT, 3D-PDF, STEP, DWG, DXF, DWF, MS Office and many more.

The latest developments of 3DViewStation can be reviewed in more detail at: https://www.3dviewstation.com/blog.html.

According to Baumann, KISTERS 3DViewStation is continuously enhanced in response to customer needs and requirements. It is available as Desktop, ActiveX, VR-Edition and HTML5 WebViewer product-versions. All product flavors are intended to be used together with a PLM, ERP or other management system product configuration or service and spare part applications, providing all necessary APIs. For cloud, portal and web-solutions, there is an HTML5-based WebViewer solution available, which does not require client installation. All file formats can be used in combination with the intelligent navigation and hyperlinking features to address the needs of complex integration scenarios.

25 years success in the market with superior visualization solutions from desktop to mobile has proven KISTERS to be one of the top players in the visualization industry. Clients ranging from small firms to well-known multinationals, 3DViewStation’s easy-to-use interface is suitable for all user groups and 100% customizable to each individual’s specific requirements. More than 3,000 customers and over 200,000 installations worldwide. In addition, KISTERS offers expert advice and support in concept development based on client requirements.

www.3dviewstation.com

KISTERS AG

Pascalstraße 8 + 10

52076 Aachen

Telefon: +49 (2408) 9385-0

Telefax: +49 (2408) 9385-555

http://www.kisters.de

2D/3D Viewer

Telefon: +49 (2408) 9385-171

Fax: +49 (2408) 9385-555

E-Mail: Germar.Nikol@kisters.de

![]()