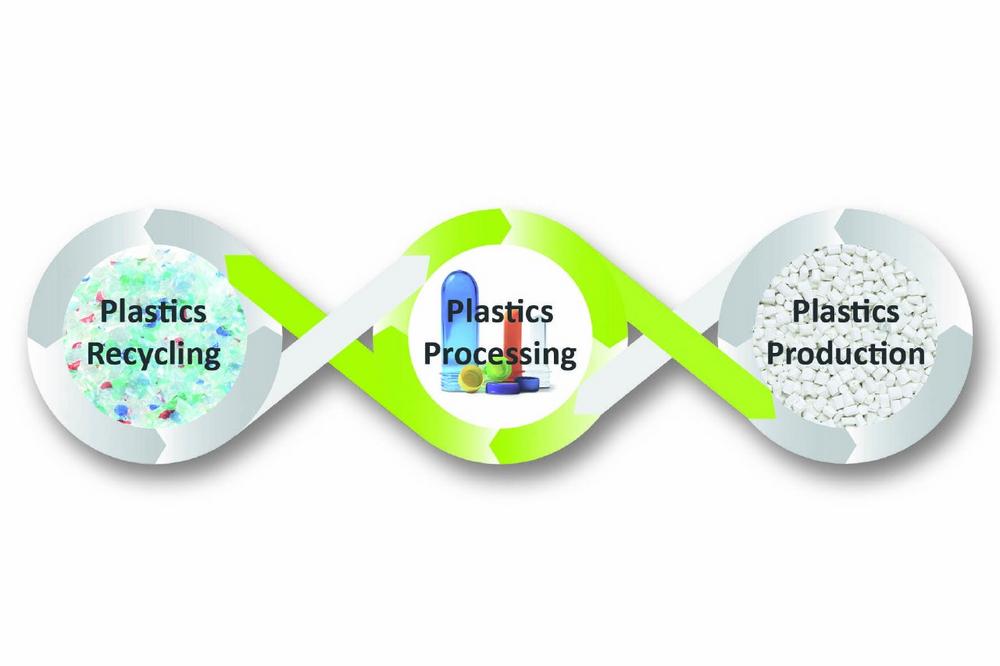

The circular economy presents manufacturers, processors and recyclers of plastic with a wide range of challenges as well as numerous opportunities. Virtually everyone knows that the raw materials to make new products are available in limited quantities. Yet plastic is still a valuable commodity at the end of its life cycle. The key is to make the circular economy a success by involving all stakeholders so that everyone benefits.

Andreas Reckziegel, Group Director Sales Division Product Inspection, says: “Plastics manufacturers and processors are going to use more and more recyclates – first because they have to, second because the products are designed to be recyclable, and third because it is more appealing to do so from a price perspective. So manufacturers and processors need to make sure that the quality of the material they’re processing is very high. Quality assurance is tremendously important.”

The economic side of using recyclates

As Andreas Reckziegel says, lower costs and the political and social pressure to increase the proportion of recycled material are the reasons why plastics manufacturers and processors are looking to use more recyclates. Often, an adequate amount of sufficiently high-quality recycled material is not available, forcing plastics manufacturers and processors to use lower-quality

constituents. This compromise is associated with substantial risk, since it can negatively impact process efficiency due to unscheduled machine downtime or lower quality of finished products, or because recyclates may simply be unsuited for use. The result is a loss of efficiency and price advantages.

To create a plastic cycle in line with the aim of achieving a circular economy, recyclers need to receive material of sufficient quality and process it with the utmost efficiency.

How do Sesotec devices and systems contribute to the circular economy?

At its K 2019 stand, Sesotec will showcase metal detectors from its GF, PROTECTOR and RAPID PRO SENSE 6 series. The detectors can be used in a variety of material infeed applications and ensure high plant availability for processing machinery and equipment by preventing unscheduled machine downtime due to metal particles, thereby avoiding the repair costs associated with breaks in production and potential recalls. Metal detectors play an essential role in ensuring high plant availability and avoiding damage, especially when processing recyclates.

The RAPID PRO SENSE 6 metal detector, which will be unveiled at K 2019, is equipped with a newly developed reject mechanism designed for compound manufacturers that have frequent colour changes or that manufacture or process abrasive materials.

K 2019 will also see the premiere of the FLAKE SCAN plastic flake analysis system, which is designed to be the perfect size for laboratory use. Companies looking to turn recyclates into new granulate can use the FLAKE SCAN material analysis system to inspect incoming goods. In recycling, the device can be used by quality laboratories to inspect outgoing goods. So far, both branches of the industry have employed manual analytical procedures that take a lot of time and produce results that cannot be duplicated. But thanks to FLAKE SCAN, a few minutes is all it takes to get reports on the composition of various plastics and on off-colour components in consistently high quality and with reproducible results.

Another new attraction is the ASM QUASAR optical sorting system, which can be used in granulate quality assurance in plastics manufacturing to ensure that granules with black spots,for example, are removed. Along with colour, further parameters – such as surface, shape and size – can also be analysed, making the system very accurate in deciding what to keep or reject.

Sesotec sorting systems for plastics recycling can be equipped with sensors that are capable of sorting bottles, flakes or regrind according to different criteria, such as colour, shape, material or metal content. The various sensors can also be combined depending on the application. The FLAKE PURIFIER+ multi-sensor sorting system, on display at Sesotec’s stand, features high-precision contaminant separation and reduced loss of good material. The special material infeed system, extra-fine valve grid and optional integrated resort track on the FLAKE PURIFIER+ increase efficiency during the recycling process, especially when dealing with highly contaminated input material.

Service rounds off the circular economy

At K 2019, Sesotec is set to showcase not only proven and new devices and systems alike, but also its wide range of service offerings. From expert advice and commissioning to maintenance packages and digital services such as predictive maintenance, Sesotec offers a full range of support to help customers ensure maximum machine availability and optimum performance. Using the new VISUDESK visualization program, all Sesotec devices in a plant can be monitored and controlled. The basis for this is an OPC UA machine communication model that is implemented on the devices.

Michael Perl, Group Director Sales Division Sorting Recycling: “K 2019 is proof positive that a circular economy is no easy task and that our metal detectors, material analysis systems, sorting systems and services offer benefits for everyone involved in the plastic cycle: manufacturers, processors and recyclers. All that makes this year’s K event more exciting than ever for us.”

Sesotec is one of the leading manufacturers of machines and systems for contaminant detection and material sorting. Product sales primarily focus on the food, plastics, chemical, pharmaceutical, and recycling industries. Sesotec’s global presence includes subsidiaries in Singapore, China, USA, Italy, India, Canada and Thailand, and more than 60 partners all over the world. The Sesotec group presently has 570 employees.

Sesotec GmbH

Regener Strasse 130

94513 Schönberg

Telefon: +49 (8554) 3080

Telefax: +49 (8554) 2606

https://www.sesotec.com/emea/de?utm_source=pressebox&utm_medium=link&utm_campaign=corp&utm_term=de

Marketing & PR

Telefon: +49 (8554) 308-2100

Fax: +49 (8554) 2606

E-Mail: brigitte.rothkopf@sesotec.com

![]()