It does not run without Execution

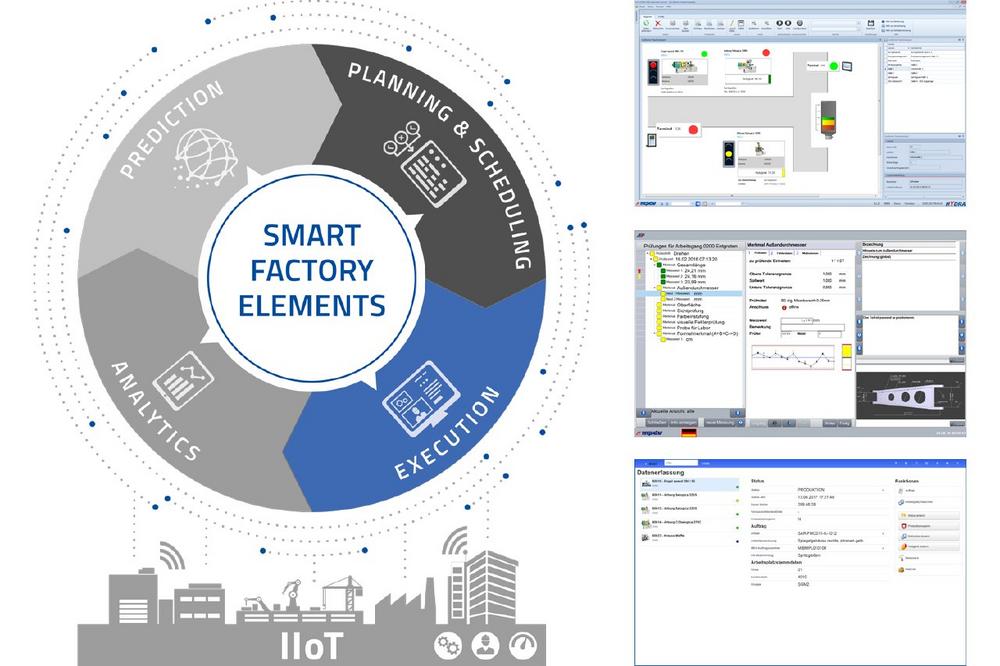

The Execution element covers a wide range of functions and applications that ensure that day-to-day production runs smoothly. These include, for example, logging on and off orders at a machine, posting material consumption and performing quality inspections. Also real-time visualizations for the purpose of condition monitoring must not be missing here. In short: Execution is all about the here and now.

Core competence of an MES system

As the name suggests, "Execution" belongs to the core competence of a Manufacturing Execution System (MES) such as HYDRA from MPDV. A large part of the functions offered by HYDRA can be assigned to the Execution element – independent of the classic subdivision according to shop floor, quality and personnel.

The MES HYDRA already meets most of the requirements that the "Smart Factory Elements" model places on a modern IT tool for Manufacturing Execution. The increased use of results from Artificial Intelligence and machine learning will successively expand existing applications or even create new ones.

More about the Smart Factory Elemens model at http://mpdv.info/prsfeexecution

More about MES HYDRA at http://mpdv.info/prsfehydra

MPDV, headquartered in Mosbach/Germany, is the market leader for IT solutions in the manufacturing sector. With more than 40 years of project experience in the manufacturing environment, MPDV has extensive expertise and supports companies of all sizes on their way to the Smart Factory. Products such as MPDV’s Manufacturing Execution System (MES) HYDRA or the Manufacturing Integration Platform (MIP) enable manufacturing companies to streamline their production processes and stay one step ahead of the competition. The systems can be used to collect and evaluate production-related data along the entire value chain in real time. If the production process is delayed, employees detect it immediately and can initiate targeted measures. More than 800,000 people in over 1,250 manufacturing companies worldwide use MPDV’s innovative software solutions every day. This in-cludes well-known companies from all sectors. MPDV employs around 480 people at thirteen loca-tions in China, Germany, Luxembourg, Malaysia, Singapore, Switzerland, and the USA. Further infor-mation: www.mpdv.com.

MPDV Mikrolab GmbH

Römerring 1

74821 Mosbach

Telefon: +49 (6261) 9209-0

Telefax: +49 (6261) 18139

http://www.mpdv.com

Marketing Manager

Telefon: +49 (6202) 9335-0

E-Mail: n.neubig@mpdv.com

![]()