The lower the sludge volume, the lower the cost of transportation and disposal. High-performance in sludge dewatering is the decisive criterion for reducing operating costs. Since its launch in 2018, the Xelletor series has achieved impressive results in terms of throughput, polymer consumption and energy requirements. In comparison to other modern machines, it offers up to 15 % more throughput, up to 2 % higher dry solids content and up to 20 % savings in flocculant and energy consumption. In recognition of these achievements, the Xelletor series was granted the German Innovation Award 2019 and the German Excellence Prize 2019.

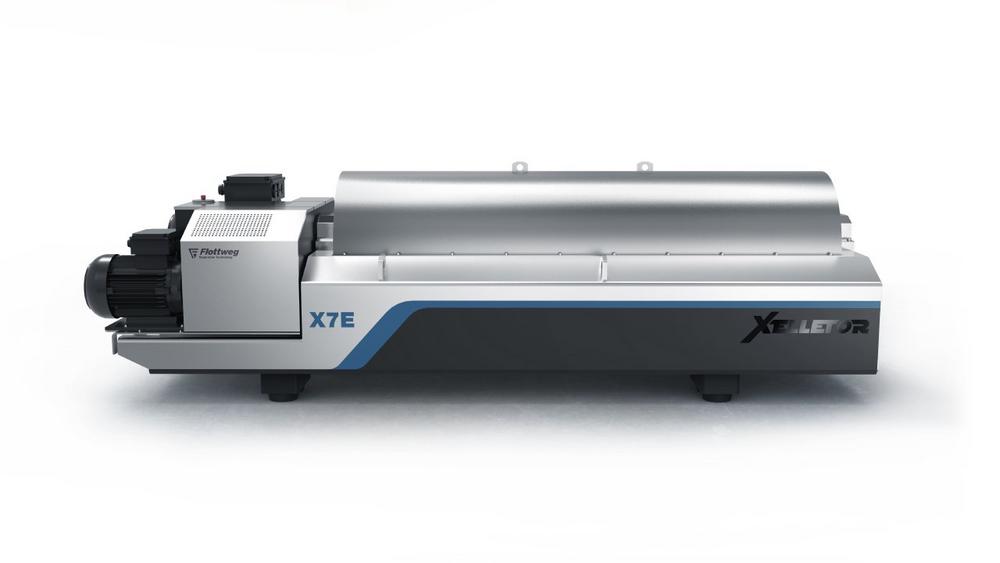

Flottweg now complements its product portfolio with the top of the range X7E. The newest Xelletor development has a capacity of up to 130 m³/h and is therefore suitable for medium to large sewage treatment plants.

Automation in the treatment of sewage sludge

Automation has become a popular buzzword in recent years. Having said this, Flottweg will demonstrate what automation can mean for operators of municipal sewage treatment plants. The separation technology specialist from Lower Bavaria offers its customers a comprehensive package for the full automation of sewage sludge dewatering and thickening.

The package includes inter alia:

- Intake regulation for the optimization of results

- Thick sludge control for optimizing the operation of digestion towers

- Centrate regulation for optimal control of the polymer supply

- Machine monitoring for optimum operational safety

The advantages are rather obvious. Thanks to the fully automatic operation, employees can usually focus on other tasks. The company is not bound by weekly working hours. Wastewater treatment plant operators often use the technology to operate 24 hours a day, 7 days a week.

Hall A1, Booth 550

Flottweg Engineered for Your Success

Specializing in separation technology, Flottweg is a family business with the goal of always achieving tangible success for the customer. With an annual turnover of over 200 million euros and an export quota of over 80 percent, Flottweg is one of the world’s leading manufacturers of centrifuges, equipment and systems. With over 60 years of experience, Flottweg guarantees the highest product quality – Made in Germany.

Flottweg maintains its own subsidiaries in the form of sales and service centers in the USA, the People’s Republic of China, Russia, Italy, Peru, Brazil, France, Australia and Mexico.

Flottweg always knows what is important to operators and works daily with this knowledge to find the optimum solution for its customers.

Flottweg SE

Industriestr. 6-8

84137 Vilsbiburg

Telefon: +49 (8741) 301-0

Telefax: +49 (8741) 301-300

https://www.flottweg.com

PR Manager

Telefon: +49 (8741) 301-1577

Fax: +49 (8741) 301-303

E-Mail: enge@flottweg.com

![]()