MEGLA provides solutions for the digital transformation, predictive maintenance, Industry 4.0 and the Internet of Things. Production companies can use the manufacturing app (mApp) MEGLA IoT Suite Connector to connect machines and sensors easily and quickly to MPDV’s MIP. The mApp Bridge MIP to OSIsoft PI can be used to connect order data of the MIP with process data. As a result, MEGLA creates a uniform data infrastructure and provides new opportunities to increase efficiency along the value chain.

"We want to solve the problems of our customers. To do so, we rely on a strong network. MPDV is the ideal partner for us. MPDV complements our portfolio with its extensive range of IT solutions for the manufacturing sector", says Julian Dohle, Managing Director, MEGLA.

"We are also pleased to have gained MEGLA as a partner for our MIP. MEGLA’s solutions offer real added value to our ecosystem in the field of machine connectivity," says Thorsten Strebel, Vice President Products, MPDV.

About the MIP

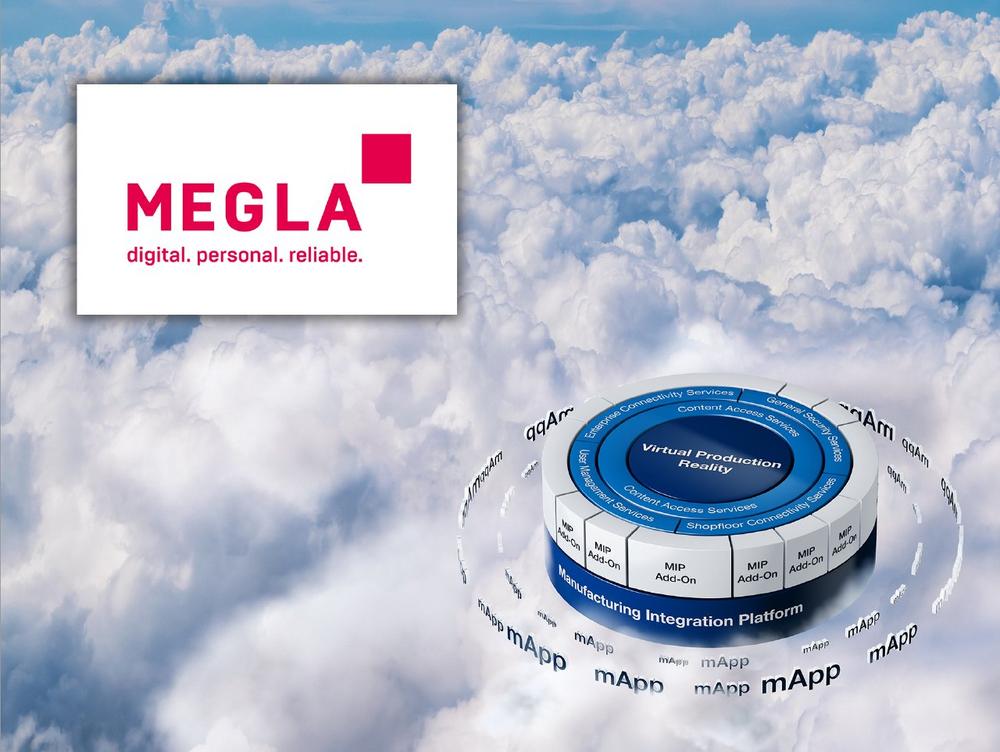

Manufacturing processes are becoming increasingly complex. This is the reason why today’s companies are asking for flexible platform solutions allowing to program applications according to their specific requirements and to combine applications from different providers. MPDV’s MIP is the first solution of production IT that makes all this possible.

The MIP is used as a central information and data platform in production and for all connected processes. All applications communicate using a common information model guaranteeing global interoperability. MIP users select from a multitude of so-called manufacturing apps (mApps) of various manufacturers. These mApps provide different functions and can be combined according to the users‘ requirements. Companies can also develop their own mApps and offer them on the MIP marketplace. System integrators can create customized solutions from available applications for their customers. This transforms the MIP into an ecosystem of users, providers and system integrators providing completely new business models.

MPDV headquartered in Mosbach, Germany, is the market leader of IT solutions for the production sector. With more than 40 years of project experience in the production environment, MPDV has ex-tensive expertise and supports companies of all sizes on their way to the Smart Factory. Products such as the Manufacturing Execution System (MES) HYDRA by MPDV or the Manufacturing Integra-tion Platform (MIP) enable production companies to streamline their processes and stay one step ahead of the competition. The systems can be deployed to record and evaluate production-related data along the entire value chain in real time. If the production process is delayed, employees can instantly detect the problem and take proactive measures. More than 900,000 people in over 1,400 production companies worldwide use MPDV’s innovative software solutions every day. These include renowned companies from all industries. MPDV currently employs 500 people at 13 sites in Germany, China, Luxembourg, Malaysia, Switzerland, Singapore and the USA. For more information see www.mpdv.com.

MPDV Mikrolab GmbH

Römerring 1

74821 Mosbach

Telefon: +49 (6261) 9209-0

Telefax: +49 (6261) 18139

http://www.mpdv.com

Marketing Manager

Telefon: +49 (6202) 9335-0

E-Mail: n.neubig@mpdv.com

![]()